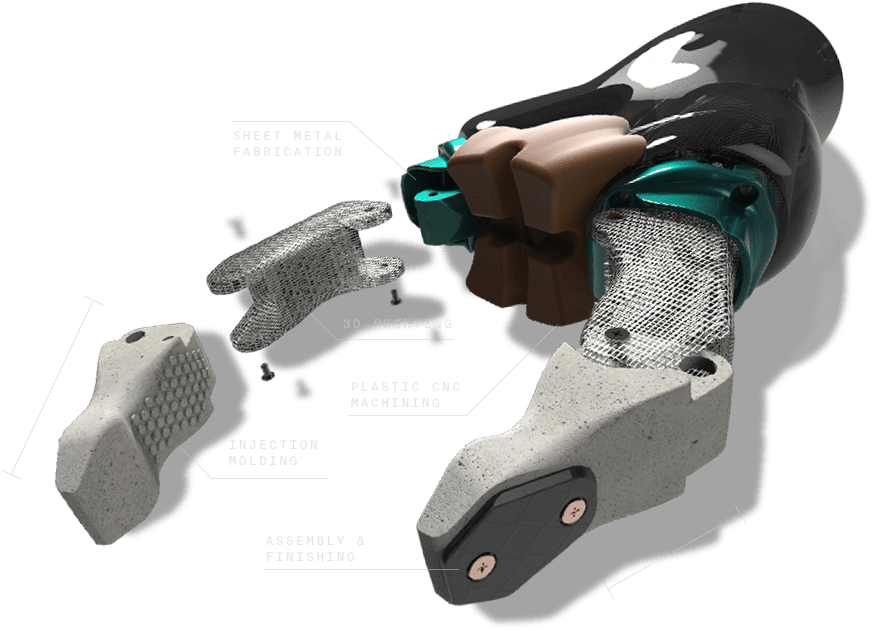

Whether it’s just for one element, or your entire product lifecycle, Fathom works with you.

Utilize Fathom’s comprehensive suite of 25+ technologies.

Fathom will work with you to identify the BEST technology and processes alongside immersive engineering support.

Benefit From … //

- Faster Product-to-Market Timelines

- Seamless Project Continuity

- Supplier Consolidation

Whether it’s just for one element, or your entire product lifecycle, Fathom works with you.

Utilize Fathom’s comprehensive suite of 25+ technologies.

Fathom will work with you to identify the BEST technology and processes alongside immersive engineering support. Benefit From … //

- Faster Product-to-Market Timelines

- Seamless Project Continuity

- Supplier Consolidation

Additive Manufacturing //

- Polyjet, SLS, SLA, FDM, FDM, MJF, STEP, DMLS

- Design for Additive Manufacturing Guidance (DAM)

- Low-Mid-High-Volume Capabilities

- Parts As Fast As Next Day

- Value-Added Post Processing and Finishing

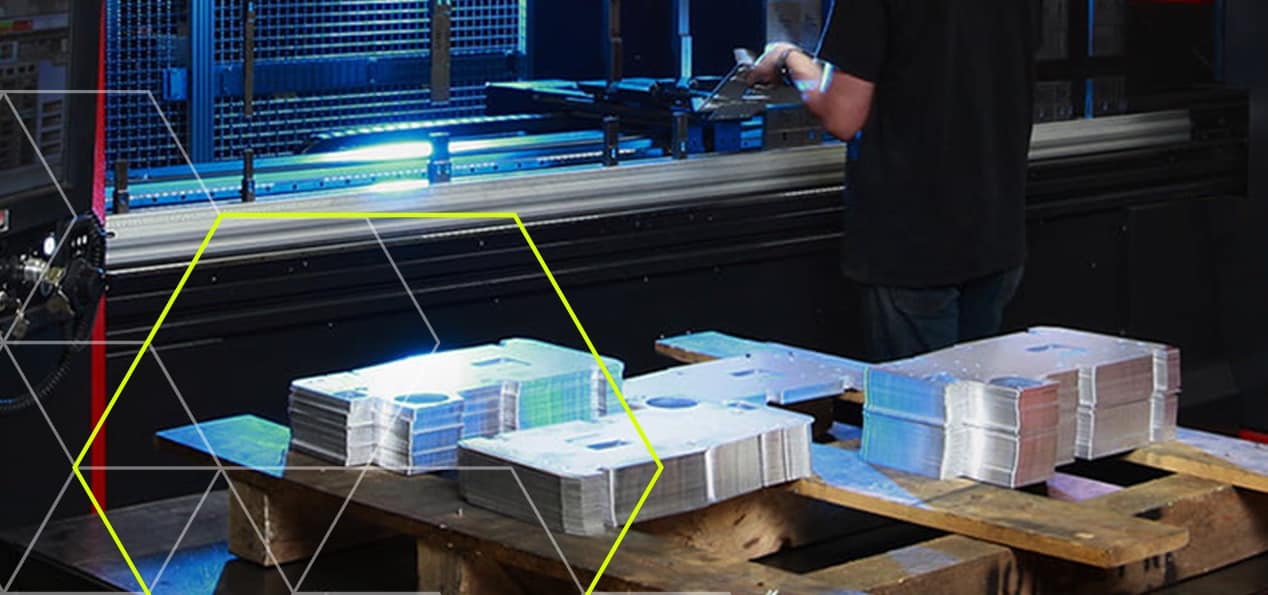

CNC Machining //

- Rapid Prototyping, Bridge-to and Production Capabilities

- Post Processing and Finishing

- 3 & 5-Axis Milling & Turning; Metal and Plastic Materials

Sheet Metal Fabrication //

- Small and Large Parts Capabilities

- Laser, Water Jet and Wire EDM Cutting

- Contract Manufacturing

- Photo Chemical Etching

Rapid Tooling + Injection Molding //

- Custom Plastic Injection Molding, Tooling, Compression Molding & DFM

- Domestic and International Fathom-Owned Sites

- Prototype and Production Molds

Urethane Casting //

- Create production quality parts (up to 200)

- Materials Mimic Production Thermoplastics Including ABS-Like, WaterClear, UL94 VO-Rated, Heat Resistant, Polypropylene-Like, Various Rubber Hardnesses, etc.

Assembly, Post Processing + Finishing //

- Sanding, Priming, Painting & Assembly

- Stock Components and Custom Artwork

- Full Finishing and Post Processing

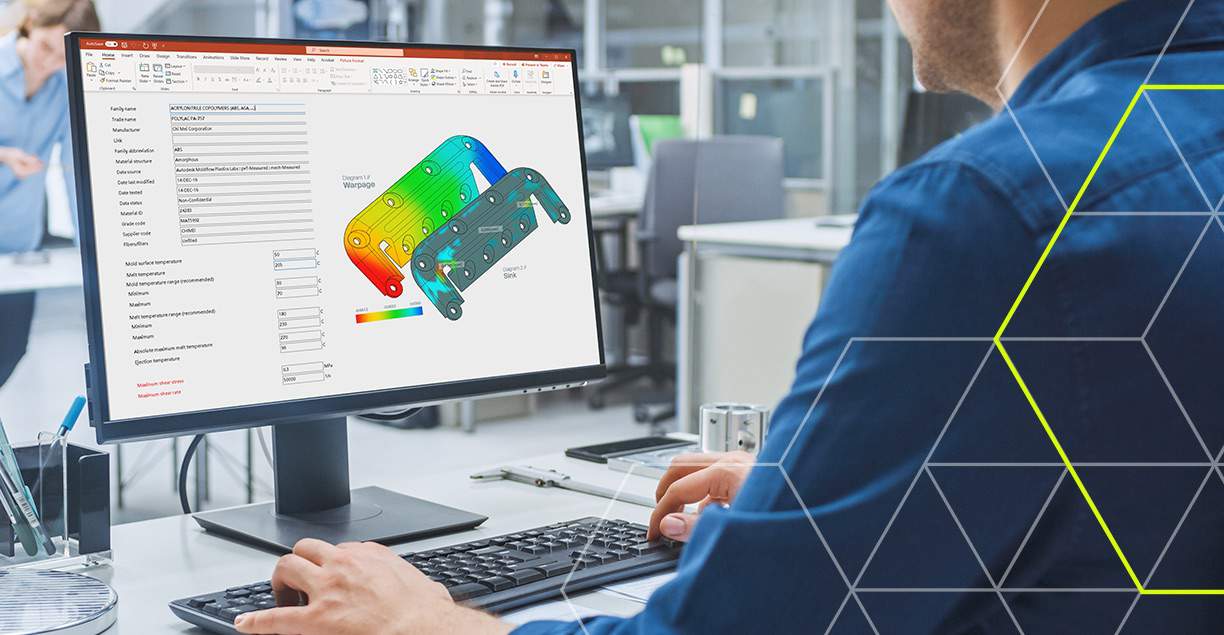

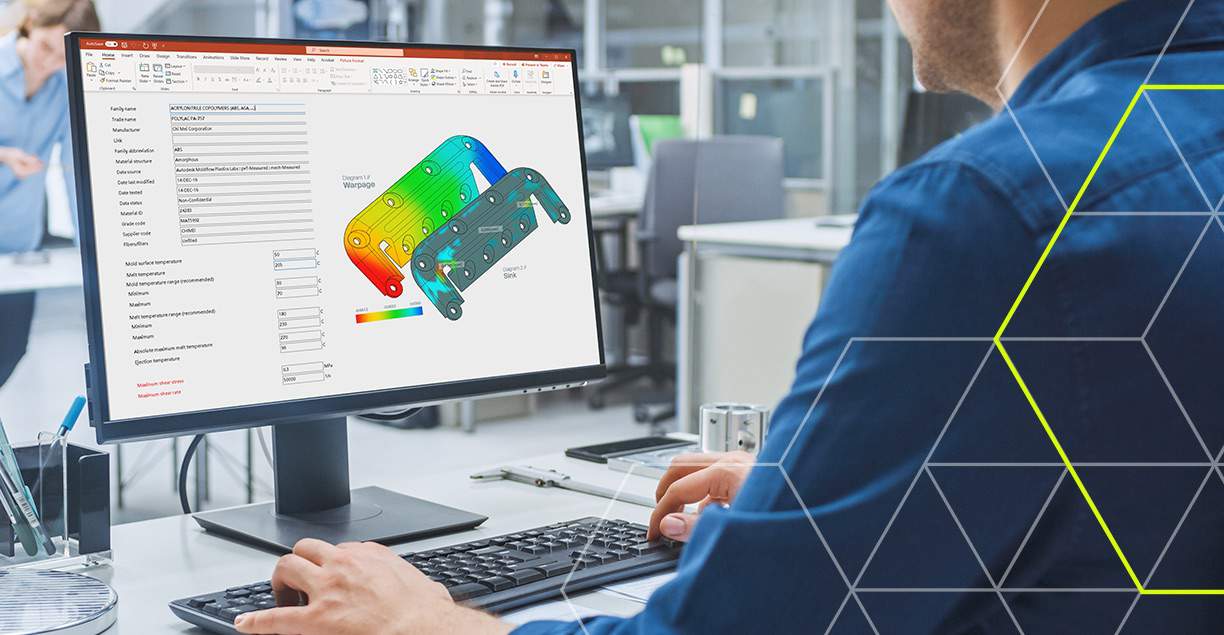

Engineering + Design Support //

- Additive & Manufacturing Expertise

- Design for Manufacturing

- Advanced Prototyping

Quality Inspection //

- Climate controlled labs

- First article and non-contact inspections

- DCC, CMM & Laser Scanning

- PPAP / PQP Submittals

Real Customers.

Real Results.

Consumer goods to industrial products. Medical to government. Fathom works with a variety of industries with complex demands, like lead times, material needs and critical certifications.

Aerospace

PROJECT //

Full size mockups of aircraft interior assemblies

TECHNOLOGIES USED //

- Additive Manufacturing

- CNC Machining

- Ancillary Tech

Automotive

& EV

PROJECT //

High-complexity quick-turn automotive bridge to production

TECHNOLOGIES USED //

- Additive Manufacturing

- Precision Sheet Meal

- Design & Enginnering

- Ancillary Tech

Government

& Defense

PROJECT //

High-complexity missile mockup

TECHNOLOGIES USED //

- Additive Manufacturing

- CNC Machining

- Design & Engineering

- Ancillary Tech

Industrial

PROJECT //

Functional generator prototype for testing

TECHNOLOGIES USED //

- Additive Manufacturing

- Precision Sheet Metal

- CNC Machining

- Ancillary Tech

Medical

PROJECT //

Bridge-to-production for medical incubator

TECHNOLOGIES USED //

- Additive Manufacturing

- Injection Molding

- CNC Machining

- Design & Engineering

- Ancillary Tech

7

of the Top 10 Fortune 500

aerospace and defense companies

choose Fathom Manufacturing*

8

of the Top 10 Fortune 500

industrial companies

choose Fathom Manufacturing*

9

of the Top 10 Fortune 500

companies in the world

choose Fathom Manufacturing*

*Excluding service companies

Real Customers.

Real Results.

Consumer goods to industrial products. Medical to government. Fathom works with a variety of industries with complex demands, like lead times, material needs and critical certifications.

Aerospace

PROJECT //

Full size mockups of aircraft interior assemblies

TECHNOLOGIES USED //

- Additive Manufacturing

- CNC Machining

- Ancillary Tech

Automotive

& EV

PROJECT //

High-complexity quick-turn automotive bridge to production

TECHNOLOGIES USED //

- Additive Manufacturing

- Precision Sheet Meal

- Design & Enginnering

- Ancillary Tech

Government

& Defense

PROJECT //

High-complexity missile mockup

TECHNOLOGIES USED //

- Additive Manufacturing

- CNC Machining

- Design & Engineering

- Ancillary Tech

Industrial

PROJECT //

Functional generator prototype for testing

TECHNOLOGIES USED //

- Additive Manufacturing

- Precision Sheet Metal

- CNC Machining

- Ancillary Tech

Medical

PROJECT //

Bridge-to-production for medical incubator

TECHNOLOGIES USED //

- Additive Manufacturing

- Injection Molding

- CNC Machining

- Design & Engineering

- Ancillary Tech

7

of the Top 10 Fortune 500

aerospace and defense companies

choose Fathom Manufacturing*

8

of the Top 10 Fortune 500

industrial companies

choose Fathom Manufacturing*

9

of the Top 10 Fortune 500

companies in the world

choose Fathom Manufacturing*

*Excluding service companies

What to Expect When You Work with Fathom

Comprehensive

Capabilities

High-Touch

Engineer Support

Unified Customer

Experience

Rapid Turnaround

Times

You shouldn’t have to choose between high quality parts or accelerated time-to-market from a manufacturing partner.

At Fathom, we strive for best-in-class and prove it with our highly skilled staff, our investments into technology, our wide-scope of capabilities and unapologetic commitment to our customers.

Prototyping

Innovate, iterate, re-iterate, validate until your R&D project needs are fulfilled. Fathom experts will support your in-house team to get you the BEST outcomes accelerating your time to market.

Design for

Manufacturability

Fathom’s in-house production capabilities are paired with a large network of specialists. You can depend on our knowledge and resources to inform key design decisions-especially manufacturing nuances for your specific project and we can carefully identify risks and optimize costs earlier in development and effectively meet challenging manufacturing demands.

Production

When your products are manufactured by us, you will benefit from our uncompromised commitment to quality. We strive to be the highest quality supplier of your parts or project with expert engineering support every step of the way. Download our linecard »

Post-Processing

Our finishing and assembly services will skyrocket your parts to production quality for a complete and finished look. We offer complete finishing and final assembly services in-house—creating turnkey finishing services that are flexible, quality-driven and cost-efficient.

Procurement &

Supply Chain Solutions

We will meet your stringent procurement requirements for contract manufacturing, single and multiple parts production. We have multiple certifications and highly unique service offerings with an acutely talented engineering team.

Committed to Quality & Security

Ready for your high-quality, compliant projects.

AS9100:2016

Certified

ISO 9001:2015

ISO 13485

Certified

ITAR

Registered

NIST 800-171

Compliant

Fathom maintains several certifications across our nationwide manufacturing network to ensure all parts are produced to exacting specifications and requirements. Talk to an Expert to kick off your specialized project today!