- From Medical Device Prototyping to High-Volume Production

- Our Medical Device Manufacturing Inspecting, Certifications and Compliance

- Medical Device Manufacturing Services

- Manufacturing Processes

- Finishing Services

- Rapid Prototyping Medical Device Manufacturing

- Common Medical Device Manufacturing Materials

- Applications of Medical Device Manufacturing

- How Medical Device Manufacturing Companies Differ

- Get Your Medical Device Manufacturing Quote Today

From Medical Device Prototyping to High-Volume Production

When your products are manufactured by us, you will benefit from our uncompromised commitment to quality. We strive to be the highest quality supplier of medical device components, surgical equipment and implant systems.

Our Medical Device Manufacturing Inspecting, Certifications and Compliance

We employ the very latest inspection equipment including Video-Based Inspection and Measuring Systems, Optical Comparators, and Coordinate Measuring Machines (CMM). We guarantee that the products you receive from us will meet your specifications and requirements. We are ISO 9001:2000 and ISO 13485 certified and FDA and DCAA compliant.

Medical Device Manufacturing Services

With Fathom, you have access to some of the industry’s top talent with unsurpassed expertise of medical device development and contract manufacturing. As your single-source vertically integrated supplier, we feature product packaging and packaging assembly services so we can handle your project from design through sterilization.

Manufacturing Processes

We are always ready to meet the demands of our customer’s medical device and component expectations by employing our cutting-edge technology, knowledgeable staff, and years of experience. When it comes to medical device manufacturing, we understand how important security and assurance are as you work to get your device to market. As a vertically integrated supplier, we can assist you with your design, product manufacturing, sterilization, and packaging assembly. We have worked with many materials, including titanium, MP35N, stainless steel, Hastelloy, Inconel, nitinol, F75, PEEK, Tecapro, Radel, and other specialty plastics and metals, including all superalloys. Allow us to review your medical device project needs and find a solution that works best for you.

Our medical device manufacturing processes include:

5-axis CNC Milling:

Using our 5-axis CNC milling capability, we can produce complex shapes with a single set-up. This streamlined manufacturing process reduces time which means you can expect a faster turnaround. Another added benefit of 5-axis machining is error reduction. The accuracy of feature-to-feature is improved as the same datum reference point is utilized throughout manufacturing. Our skilled team will provide you with a single-source manufacturing solution that meets your production needs and deadlines.

6-axis CNC Grinding:

Using our 6-axis CNC grinding capability, we can maximize productivity and accuracy. Our grinders are equipped with automatic tool loading and the ability to support more than one grinding wheel. The combination of high levels of automation and automatic in-machine tool measurement and compensation means we are capable of extended periods of unmanned production. Our 6-axis CNC grinding machines can produce components with complex geometries and strict tolerances that can be held consistently even on the most complex parts. We can meet your challenging production expectations, even if they involve exotic or rare materials.

Premium Swiss CNC Turning:

Our team consists of some of the industry’s best machinists with extensive knowledge of cutting-edge machines. The Swiss CNC machines have added to our versatility in manufacturing a diverse array of different parts. These machines are equipped with high-pressure coolant, live tooling, and c-axes. Our CNC turning machines are equipped for quick changeovers, allowing our expert operators to switch between entire families of screws by changing just a few variables. They are designed to run lights out, facilitating maximum production capacities while simultaneously reducing our clients’ costs. Lastly, we have developed complex, multi-stage broaching and in-machine deburring. Our CNC Swiss turning machines are equipped with ample memory for complicated surface programs. We can tackle your most complex design demands.

Finishing Services

To complete a finished component or medical device, we offer a wide variety of finishing processes, including titanium anodizing, electropolishing, passivation, metal polishing and finishing, micro-bead blasting, heat treatment, bending, forming, laser welding and TIG welding.

Rapid Prototyping Medical Device Manufacturing

We are known for our industry-leading talent and expertise in medical device manufacturing. Our skilled team of mold designers, machinists, toolmakers and engineers are dedicated to meeting your pressing deadlines and quality standards. When it comes to medical device manufacturing, we will provide you with a cost-effective, high-quality and fast solution, producing low-volume samples of your unique design. Contact us today to collaborate on product development, manufacturing plants, cost reduction and scale-up strategies.

Common Medical Device Manufacturing Materials

We have experience working with a wide variety of materials for medical device manufacturing, including:

- Titanium

- NiTi

- MP35N

- Stainless Steels

- Hastelloy

- Inconel

- F75

- Super Alloys

- PEEK

- Tecapro

- Radel

- Other specialty plastics

Applications of Medical Device Manufacturing:

We are capable of producing high-quality medical devices, including:

- Biopsy forceps cups

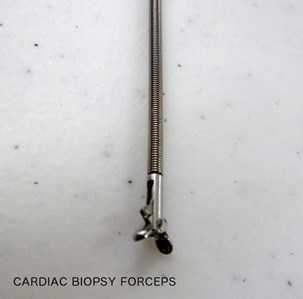

- Cardiac biopsy forceps

- Heart stabilizer

- Laparoscopic curved scissors

- Laparoscopic instruments

- Endoscopy device components

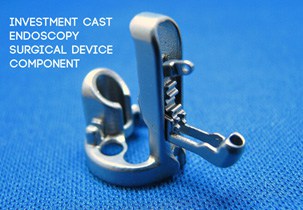

- Investment cast endoscopy surgical device components

- Investment cast surgical device components

- Vascular

- Reusable medical devices

- Orthopedic

- Gastrectomy

- Hemorrhoidectomy

- Bypass

- Cauterization

- Angioplasty

- Aspiration

- Closure devices

- Single-use medical devices

- And more!

How Medical Device Manufacturing Companies Differ

Different medical device manufacturing companies can differ based on the specific type and volume of production they offer. Each will come with specific expertise and may specialize in different areas or specific devices and components. With Fathom, you have access to some of the industry’s top talent with unsurpassed expertise of medical device development and contract manufacturing.

Get Your Medical Device Manufacturing Quote Today

Ready to begin your medical device manufacturing process? Get started with an online quote.