Sheet Metal Prototyping

- Bring Your Products to Market Faster

- Leverage Our Extensive Metal Prototyping Expertise

- Accountability // All Services Under One Roof

Get a Quote

Or Any of Our 25+ Manufacturing Processes

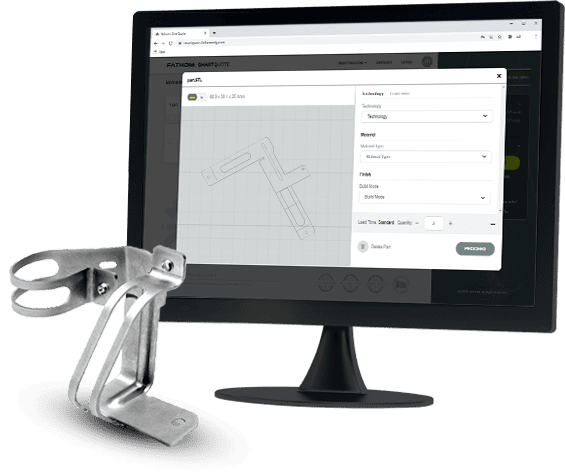

Need Sheet Metal Prototype Parts Fast?

Fathom Manufacturing Makes It Possible

Bring Your Product to Market Faster

Fathom’s quick turnaround on prototype parts makes it possible to iterate your way through multiple design variations and bring your product to market faster.

Comprehensive Prototyping Capabilities

When you need sheet metal prototype parts quickly, Fathom is ideally equipped to meet your needs. From sheet metal fabrication and precision forming of small, complex parts plus a full range of cutting, forming and finishing technologies, we’ve got you covered.

Sheet metal prototype parts can help eliminate the guesswork in manufacturing while reducing overall costs. Prototypes act as a physical example of a concept, making it easy to explain product features and benefits to others. Metal prototypes also allow designers to validate their form, fit and functionality.

Sheet Metal Prototyping // Cutting

Fathom offers multiple options for metal cutting to meet your needs:

Laser Cutting

Perfect for high-quality prototyping, laser cutting offers excellent cut quality with minimal heat-affected zones.

Water Jet Cutting

When you need precision metal parts cut with a high degree of accuracy, water jet cutting is a versatile and cost-effective solution. Fathom’s large-format water jet machines can cut materials up to 6 inches thick with a tolerance of 0.005″- 0.015″.

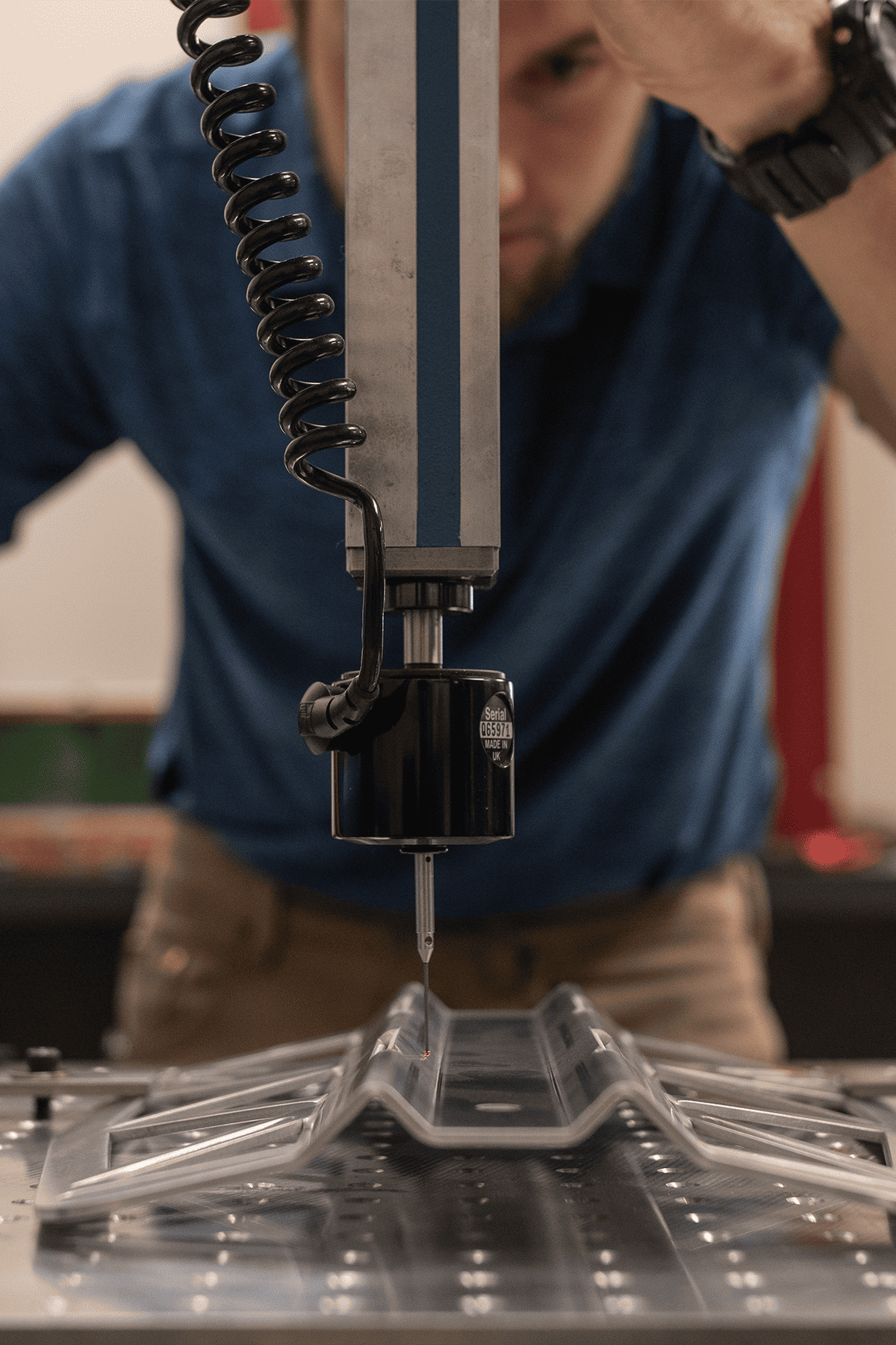

Microcut™ Cutting

When you need exceptional precision for high-tolerance metal parts, micro water jet cutting can help you achieve the results you seek. Fathom’s Microjet machines can cut materials up to 0.5 in. thick with a tolerance of 0.0005- 0.005 in. It’s faster than cutting fine features with EDM and doesn’t create heat-affected zones.

Wire EDM

When you need to cut tough metals with precise tolerances, wire EDM cutting works well. It uses a wire charged with an electric current to melt the material adjacent to the wire, resulting in a very precise cut that requires little or no additional processing.

Photo Chemical Etching

This unique machining process uses films, masks and chemical etchants to produce complex and highly accurate flat metal parts that is less expensive than other subtractive manufacturing methods. Because it doesn’t require work-holding fixtures or tooling, it’s ideal for rapid prototyping.

Sheet Metal Prototyping // Forming

We offer a number of ways to transform your ideas into finished metal parts:

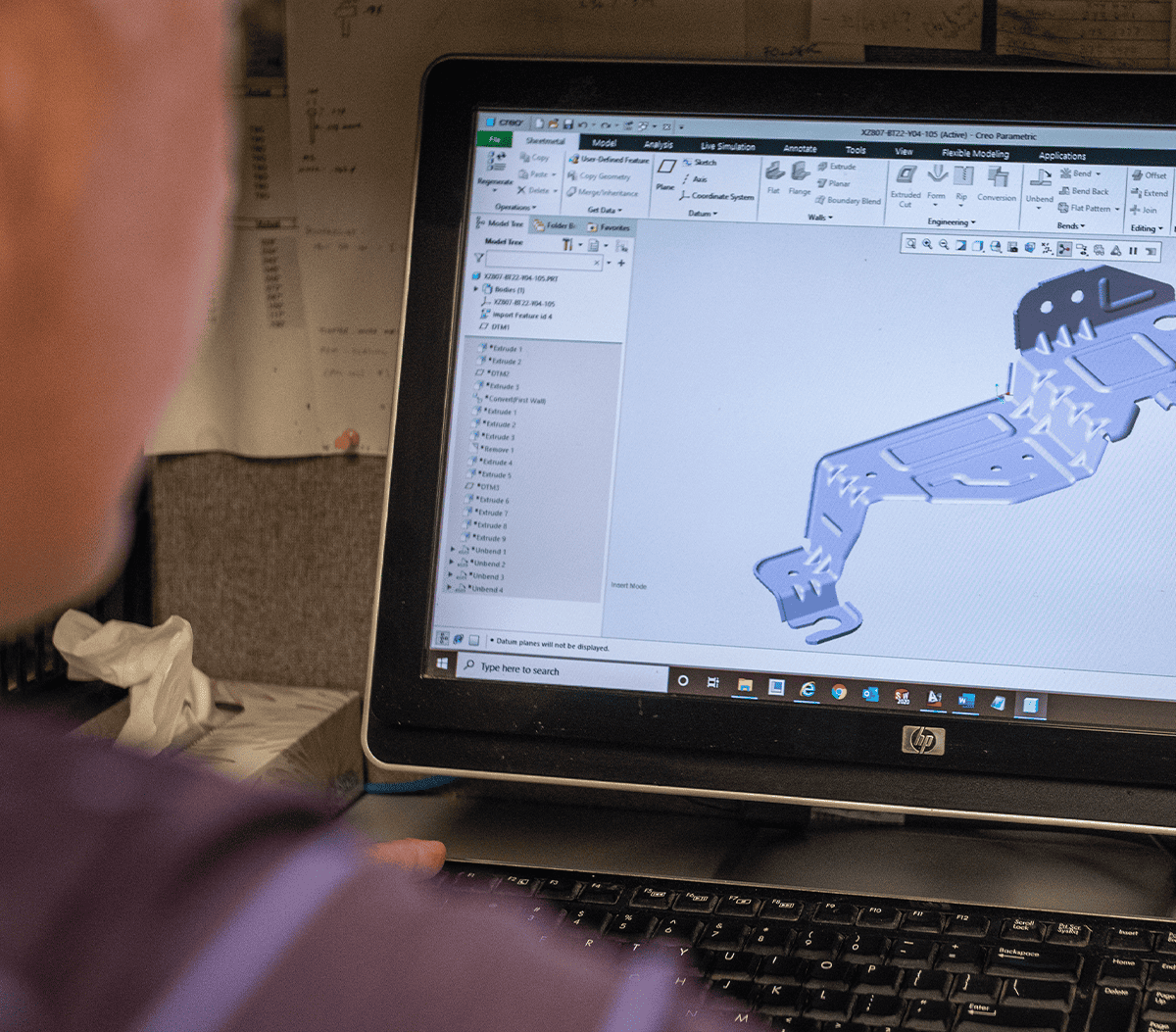

Multi-Stage Modular Tooling

Need precision forming for prototype parts? We have developed a technique in which we turn an ordinary press brake into a manual progressive die. By combining this dynamic technique with our custom-built in-house tooling, we can easily achieve even the most intricate and complex design specifications.

Four-Slide and Multi-Slide

With this machine, we can produce parts in seconds that take hours to form on a traditional press brake. Four-slide and multi-slide manufacturing is ideal for producing small and intricate springs, brackets, electrical terminals, clips and battery contacts. All tooling is designed and built in-house by our Fathom team.

Specialty Stamping

Our skilled and creative toolmakers can build complex tooling solutions as needed to manufacture even the most challenging stamped parts.

Industry Applications

Sheet metal prototypes are valued in many industries. Here are some of the ones we’ve worked on:

Automotive // From brackets to interior trim, sheet metal prototype parts help automakers innovate their designs faster.

Aerospace // The foundation of the aerospace industry is based on new product innovation. Our team can meet its needs for complex designs, tight tolerances and responsiveness to their evolving needs.

Defense // The defense industry requires high precision and efficiency standards for weapons, vehicles and more. Fathom is an ITAR-registered manufacturer and defense contract supplier that can support all military and homeland security projects.

Electronics // The electronics industry requires parts with tight tolerances and high surface quality. Whether your electronics project needs a simple or complex design, Fathom can deliver.

Industrial // Parts for the industrial industry must provide reliable service in a variety of demanding environments. Our team can help you develop rugged and functional parts from prototype to full production.

Life Sciences // The medical industry sets high standards for both quality and cleanliness. Fathom has produced small parts for many types of medical devices, including enclosures, brackets, springs, connectors and contacts.

Prototyping with Sheet Metal

vs. Other Technologies

Sheet metal prototyping offers several key advantages, including:

Cost // Compared to machining, sheet metal fabrication is much less expensive and provides a lot of flexibility during each step of the fabrication process.

Validate Before Tooling // Sheet metal prototyping enables engineers to validate a part design before investing hundreds of thousands of dollars in production tooling.

Functionality Testing // Additive prototypes may be useful for fit and finish, but they aren’t usually functional. Metal prototypes can be used for functionality testing, too.

Speed // The Fathom team can turn around prototype parts in as little as six to eight business days – perfect for rapid iteration of product designs. Metal prototype parts can help you bring your products to market faster.

Why Choose Fathom’s Sheet Metal Prototyping Services?

Fathom has the expertise and technology to help you meet your needs faster.

Fathom has over 20 years of experience prototyping small sheet metal parts. When you bring your drawings to us, we’ll get back to you quickly with an initial assessment and a quote. Once we have an agreement to go forward, we’ll conduct a detailed DFM to assess and help improve your part’s manufacturability. We’ll be with you every step of the way, from prototyping through production.

Get your first delivery of parts in 6 to 8 business days by prototyping with Fathom Manufacturing.

Additional Resources

Fathom Ithaca (Fathom’s Experts in Small Sheet Metal Prototyping)

Fathom Denver (Fathom’s Experts in Large Sheet Metal Prototyping)

Fathom Newark (Fathom’s Experts in Photo Chemical Etching)