Fathom Manufacturing //

Domestic

Injection Molding

Skip the logistics and supply chain issues

with injection molding right here in the US.

Looking for offshore or hybrid injection molding? Contact our experts to find the perfect solution for you!

Skip the Logistical

Challenges Typically

Associated with

Offshore Production

US-Based and Certified

with 35 to 600 Ton Presses,

Bi-Injected Presses, and

ISO 900:2015 Certification

Convenience of

Real-Time On-Site

Trialing to Ensure

Project Specifications

Advanced Mold Making

Technologies with

3D Printing and

Automated EDM Cells

Our Fathom Experts recognize the value of having design and manufacturing collaboration at any stage in the product development process, and a DfM analysis is available with every quote. Our diverse group of engineers, designers and builders help you navigate the right process, materials and more for each stage of your product development – from design and prototype, to validation for mass-production.

And with easy quoting and intuitive project management tools through our SmartQuote platform, you can move rapidly and confidently through your product’s lifecycle, navigate supply chain distruptions, and to deliver to market blazingly fast.

With over 530+ machines across 25+ manufacturing processes, Fathom scales with your needs, from prototype, to bridge, to production qualities.

![]()

Easy Quoting and Project

Management in SmartQuote

Platform, with Access to

Engineering Feedback

![]()

Comprehensive and Diverse

Manufacturing Processes,

with 25+ Different

Manufacturing Processes

Across the Fathom Brand

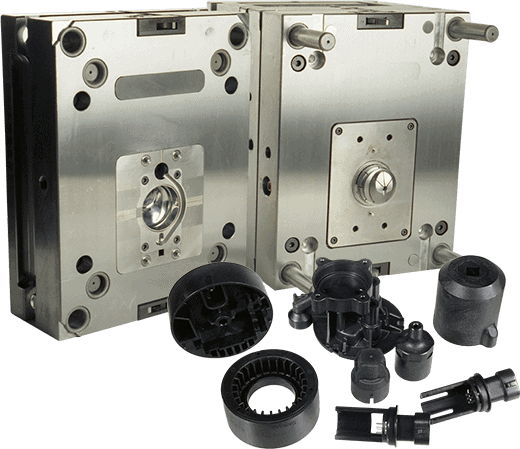

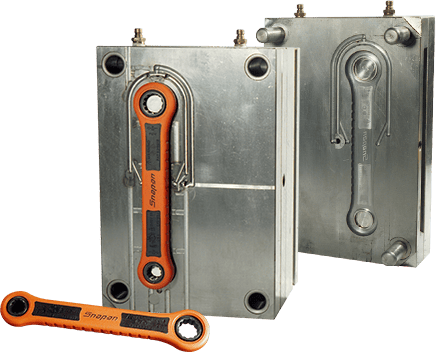

Fathom provides high-quality plastic injection mold design, precision mold making, and close-tolerance injection molding services for a complete custom manufacturing experience. Fathom utilizes state-of-the-art mold making technologies to provide high-quality plastic injection mold design, precision mold making and close tolerance injection molding services for small–to–medium injection molds projects. Fathom works closely with our customers in the medical, packaging, consumer technology, automotive and electrical industries that require optimized productivity and overall lowest manufacturing cost to find the perfect solution.

The focus in today’s prototype world has been to create prototypes which mimic the production component, in the areas of precision, part weight, cycle times, and tooling costs. Our goal is to ensure that we meet and exceed our customers’ expectations with prototypes that are delivered quickly, accurately. Our process begins with meeting and discussing the goals of the customer prototype component and deciding as to the type of prototype tooling that fits their needs.

Production cycle times are one of the most critical factors when considering piece part costs as it relates to the type of production tooling features. Production tools need to process, cool, and eject parts quickly. There are many factors to consider when trying to achieve optimum cycles and we offer many techniques and have succeeded with over our many years of experience and knowledge of doing prototype components. In addition, our speed and cost efficiencies through machining and EDM cell automation allows our lead times and cost to be significantly lower than competitors.

Additional advanced tooling includes:

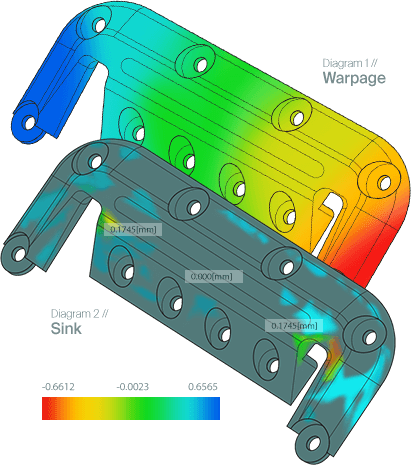

Fathom will review your quote and alert you of any potential issues that need to be acknowledged and discussed, and/or problem areas that need to be redesigned, like a necessary draft angle for ejection, or a thick wall that may cause a sink mark.

We will advise you of these situations and always make sure you are in agreement with changing your model. There may be cases where the situation is not critical to you and you approve for us to proceed with your model as-is, but at least we will have brought it to your attention. You are always in control!

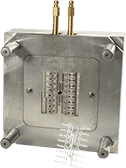

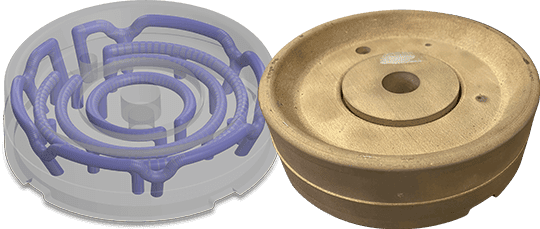

A leader in industrial closures and packaging components was having assembly issues in the field due to a particular part feature warping, which limited its cap functionality. This faulty feature was caused from the long cycles necessary to cool part during the injection molding process. However due to the deep draw, it was difficult to get proper cooling into the cavity.

Fathom tooling engineers took a different approach, designing conformal cooling into a new core insert, and delivered results that saved the customer valuable time and money.

Fathom works with clients in the medical, packaging, consumer technology, automotive and electrical industries that require optimized productivity and overall lowest manufacturing cost.

With over 100 years of tool building experience, Fathom stands above the rest for your customer experience. Gain access to:

Start a quote today or talk with one of our experts!

Precision manufacturing

from coast to coast.

HEADQUARTERS //

1050 Walnut Ridge Drive

Hartland, WI 53029

877-328-4668

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

480-966-2300

CALIFORNIA

46758 Lakeview Blvd

Fremont, CA 94538

COLORADO

7770 Washington St.

Denver, CO 80229

303-288-6855

FLORIDA

14000 N.W. 58th Court

Miami Lakes, FL 33014

305-889-3280

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

815-385-7500

1401 Brummel Ave

Elk Grove, IL 60007

847-952-8088

MINNESOTA

13758 Johnson Street NE

Ham Lake, MN 55304

763-755-7575

NEW YORK

1920 Slaterville Rd.

Ithaca, NY 14850

607-277-7070

401 W. Shore Blvd.

Newark, NY 14513

315-331-7680

TEXAS

1513 Sam Bass Rd.

Round Rock, TX 78660

512-255-1477