Additive Manufacturing or additive layer manufacturing is used to create durable and lightweight parts. Additive manufacturing uses Computer-Aided-Design (CAD) or a 3D model to direct hardware how to build an object in successive layers. The CAD drawing provides a set of instructions or blueprints, illustrating all the intricacies of the product being manufactured. These blueprints instruct the machine where and when to place the material. Complex objects can be produced in this manner without the need to join together separate parts. This eliminates post-processing labor and can reduce overall cost. Some examples of products made using additive manufacturing technologies include surgical implants, parts for aerospace and defense industries, automotive parts, and rapid prototypes. Additive manufacturing is used by vastly different industries. The wide variety of materials available in additive manufacturing allows designers to easily create industry-specific products and parts.

Polymers, metals, and ceramics are the three primary types of materials that can be used for additive manufacturing. These materials are commonly available in powder or wire feedstock. Additional materials include paper, adhesive paper, chocolates/food, and polymer/adhesive sheets for Laminated Object Manufacturing. It is possible to print nearly any material using the additive manufacturing method of layering. However, the process can alter the microstructure of the material due to the high heat and pressure used during additive manufacturing. The chosen material can also affect the finish. Material characteristics may not be the same during pre-manufacture as they are post-manufacture.

Polymers are common plastics like Acrylonitrile Butadiene Styrene (ABS) and Polycarbonate. This category also contains waxes, epoxy-based resins, and structural polymers. Polymers become soft when heated but will regain firmness after cooling. Polymer powders can be mixed with other polymers or materials to create alloys that have different structural and aesthetic properties. Polymers used in additive manufacturing include / /

Different metals can be used for additive manufacturing. Metal for additive manufacturing begins as either powder or filament. Parts made from metal retain superior mechanical properties. Metals used in additive manufacturing include / /

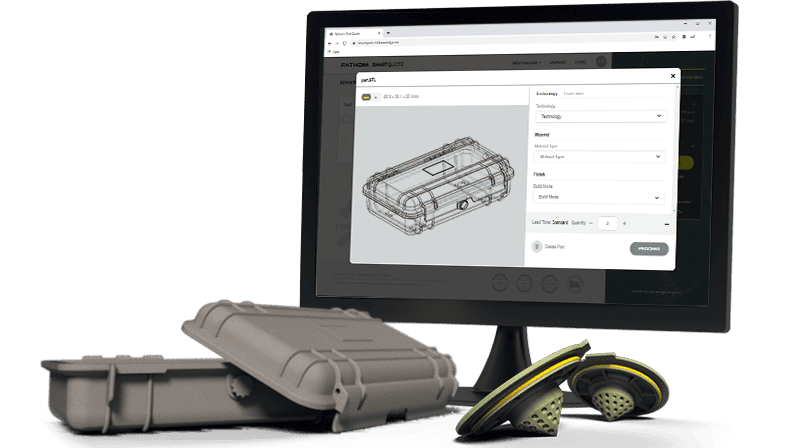

Fathom offers a wide variety of materials for additive manufacturing. Selecting the best medium for your unique part is critical to producing a viable product. Fathom offers six additive manufacturing technologies with a diverse range of material options.

PolyJet technology is capable of creating smooth surfaces, thin walls, and complex geometries all while holding tolerances within 0.1 mm. PolyJet is the only technology that supports a wide selection of materials with properties that range from rubber to rigid and transparent to opaque. PolyJet can also 3D print with multiple materials in a single build. This allows designers to achieve combinations of colors and characteristics without secondary processing. Parts requiring a hard shell and soft grips can be made in one shot and be put directly to use.

How does PolyJet technology work? PolyJet is a photopolymer-based jet printing process that distributes material droplets, layer-by-layer, onto a build platform. Each layer is immediately cured with a flash of UV light. The object is fully cured and can be handled immediately without post-curing at the end of the build process. PolyJet technology utilizes a water-soluble gel as a support material. The gel material is designed to provide support for complex geometries during the printing process but can easily be removed after manufacturing. The gel dissolves in water or can be water jetted for faster removal.

| TYPE | MATERIALS | DESCRIPTION |

|---|---|---|

| Simulated ABS | Digital ABS Plus (Ivory) |

|

| Transparent | Vero Clear |

|

| Rigid Opaque | Vero Pure White, Vero Black Plus, Vero White Plus, Vero Yellow, Vero Cyan, Vero Magenta, Vero Blue |

|

| Simulated Polypropylene | Rigur (White) |

|

| Rubber-like | Agilus30 (Clear), TangoBlack+ |

|

| Digital Materials | Predetermined blends of the above materials |

|

*Parts over 250mm in any dimension require quote review.

Additional Flexible 3D Printing Options / / TPU 92A for FDM, TPU 88A for SLS & Urethane Casting

Order Material Samples // Keychains & Kits

PolyJet Parts In As Soon As Same Day / / Get A Quote

Stereolithography (SLA) technology is ideal for larger parts that need high-resolution finishes. It is an extremely cost-effective solution for creating durable, aesthetically pleasing medium- or large-sized items on a tight deadline. SLA resins are available with extremely high heat deflection. These materials are an excellent choice for building molds or inserts.

How does the SLA technology work? Like PolyJet, SLA uses photopolymer resins that are cured with an ultraviolet laser. The UV laser traces a shape dictated by the original file across the surface of the resin bath. The resin touched by the laser hardens, then the build platform descends in the resin bath, and the next layer is added. This process is repeated until the entire part is complete.

SLA offers a combination of high-quality resolution and surface finishes for large pieces. SLA is also very effective at faithfully capturing the intricacies of even the most complex parts. Clear 3D printed SLA resins can achieve colorless clarity with additional post processing to mimic clear plastics. SLA specializes in creating parts that may be very cost-intensive to produce using any other method of manufacturing. Parts made with SLA are consistently used for trade show models, aesthetic parts, and snap fits/functional assemblies.

| STANDARD SLA MATERIALS |

LEAD TIME | OPTIMAL QUANTITY |

MAXIMUM DIMENSIONS | SUGGESTED MINIMUM WALL THICKNESS |

FINISH & APPEARANCE |

ADVANTAGES & CONSIDERATIONS |

|---|---|---|---|---|---|---|

| Accura 25 | 1-3 Days* | 1-10 parts | 650 x 750 x 550 mm | 1mm |

|

|

| Accura Clearview | 254 x 254 x 254 mm |

*Parts over 250mm in any dimension require quote review.

SLA Parts In As Soon As Next Day // Get A Quote

Fused Deposition Modeling (FDM) technology is ideal for building concept models, functional prototypes, and end-use parts using standard, engineering-grade, and high-performance thermoplastics. The FDM process uses the same types of raw materials used in the injection molding process. This gives FDM a distinct advantage over other additive manufacturing technologies by allowing designers and engineers the chance to work with a finished product before going into mass production.

How does FDM technology work? FDM is a filament-based additive technology with a moving print head that extrudes a heated, thermoplastic material in a pattern, layer-by-layer, onto a build platform. This technology includes the use of support material to create supportive structures that are removed by force or dissolved in solution.

The FDM technology was invented 30 years ago by Stratasys founder Scott Crump. The FDM process uses the same production-grade thermoplastics found in traditional manufacturing processes. FDM is ideal for applications that require tight tolerances, extreme toughness, and environmental stability. Material options include specialized properties like electrostatic dissipation, translucence, biocompatibility, VO flammability, or FST ratings.

FDM Materials

| MATERIALS | DESCRIPTION |

|---|---|

| TPU 92A (thermoplastic polyurethane elastomer) |

|

| Antero™ 800NA (polyetherketoneketone) |

|

| ULTEM™ 1010 resin (polyetherimide) |

|

| ULTEM 9085 resin (polyetherimide) |

|

| FDM Nylon 12™ (polyamide 12) |

|

| FDM Nylon 12CF™ (polyamide 12CF) |

|

| PC (polycarbonate) |

|

| PC-ISO™ (polycarbonate – ISO 10993 USP Class VI biocompatible) |

|

| PC-ABS (polycarbonate – acrylonitrile butadiene styrene) |

|

| ASA (acrylonitrile styrene acrylate) |

|

| ABS-ESD7™ (acrylonitrile butadiene styrene – static dissipative) |

|

| ABS-M30™ (acrylonitrile butadiene styrene) |

|

Consult a Fathom specialist for details on more material options.

For additional flexible 3D printing options / / TPU 88A for SLS, PolyJet & Urethane Casting

Order Material Samples / / Keychains & Kits

FDM Parts In As Soon As Next Day / / Get A Quote

Selective Laser Sintering (SLS) technology is a powder-based additive technology used to create models, prototypes, and end-use parts in durable, engineering-grade thermoplastics. SLS technology should be considered for applications that involve high-complexity, organic geometries, and extreme durability. SLS is ideal for short-run production and prototyping. The technology is also capable of producing parts with finer details than most processes when using high-strength plastics. SLS material composition is among the most robust available from additive manufacturing.

How does SLS technology work?

SLS uses a blade to spread a thin layer of powder over the build platform. A laser then shoots a cross-section of the part, fusing the powder together. The build platform then drops one layer and the process begins again until the part is finished. Parts are then excavated out of the build powder-cake and bead blasted to remove loose material. The unused powder in the build envelope acts as the support structures. Unused powder can also be reclaimed and used for the next project.

SLS Material

Specifications

| SLS MATERIALS | LEAD TIME | OPTIMAL QUANTITY | MAXIMUM DIMENSIONS | SUGGESTED MINIMUM WALL THICKNESS | FINISH & APPEARANCE | ADVANTAGES & CONSIDERATIONS |

|---|---|---|---|---|---|---|

| TPU 88A | 2+ Days | Prototypes, Low-Volume, Short-Run Production | 320mm x 320mm x 610mm | 1mm | Standard Color: White Medium/High Resolution High Detail & Complexity Dye Available (Black, Red, Blue, Green, Orange, Yellow and Pink) |

High Elasticity, Rebound & Resistance to Fatigue Water-Tight Down to 0.6mm Wall Thickness High Burst Pressure Excellent Flexibility & Durability |

| Nylon PA12 (White) | 2+ Days | Prototypes, Low-Volume, Short-Run Production | 320mm x 320mm x 610mm | 1mm | Standard Color: White Medium/High Resolution High Detail & Complexity Dye Available (Black, Red, Blue, Green, Orange, Yellow and Pink) |

Nearly Isotropic Parts Built Without Supports, Allowing for Complex Geometries Durable Production-Grade Thermoplastic |

| PA 12 Glass Bead | 3+ Days | Prototypes, Low-Volume, Short-Run Production | 320mm x 320mm x 610mm | 1mm | Standard Color: Off White Medium/High Resolution High Detail & Complexity Dye Available** (Black, Red, Blue, Green, Orange, Yellow and Pink) |

High Rigidity Resistant To Wear & Tear Thermally Resilient |

| PA 11 | 3+ Days | Prototypes, Low-Volume, Short-Run Production | 320mm x 320mm x 610mm | 1mm | Standard Color: White Medium/High Resolution High Detail & Complexity Dye Available (Black, Red, Blue, Green, Orange, Yellow and Pink) |

High Impact Resistance & Elongation At Break Higher Temperature Resistance Than PA 12 Does Not Splinter Under Load |

| PA 11 Fire Retardant | 4+ Days | Prototypes, Low-Volume, Short-Run Production | 320mm x 320mm x 610mm | 1mm | Standard Color: White | High Ductility Combined With Strength Flame-Retardant Properties Similar To ULTEM Filament |

| Carbon-Filled Nylon 11 | 4+ Days | Prototypes, Low-Volume, Short-Run Production | 320mm x 320mm x 610mm | 1mm | Standard Color: Dark Grey | High Strength Combined with Increased Impact Resistance & Elongation At Break Electrostatically Dissipative |

*Geometry Dependent

**Filled Nylons Can Have Inconsistent Color When Dyed

For additional flexible 3D printing options // TPU 92A for FDM, PolyJet & Urethane Casting

Order Material Samples // Keychains & Kits

SLS Parts In As Soon As 2 Days // Get A Quote

Multi Jet Fusion (MJF) technology is quickly becoming a popular choice for 3D printing prototypes and production parts. MJF can be used for enclosures, electronics housings, complex ducts, lattice structures, and functional assemblies. The technology is capable of 3D printing parts with high detail and durability. MJF is ideal for short production runs as the process allows for nesting in the Z-direction. To learn more about MJF, read a featured FAQ blog post by a Fathom Applications Engineer.

How does MJF technology work?

MJF builds parts by laying down a thin layer of powder on a print bed. The inkjet array in the print carriage sweeps over the print bed, jetting two agents into the powder — a fusing agent, printed where the powder will fuse together, and a detailing agent that is used to reduce fusing at the part boundary. The detailing agent enables MJF parts to achieve a high level of detail not possible with other additive manufacturing technologies.

Nylon 12 is a thermoplastic that is strong enough for functional, small- to medium-sized prototypes and production parts. It is an ideal material for complex assemblies, housings, enclosures, and watertight applications. Nylon 12 will produce smooth surfaces and fine details. It provides excellent chemical resistance to oils, greases, aliphatic hydrocarbons, and alkalis. Parts produced are a non-uniform light gray but can be dyed a darker color for a uniform appearance.

MJF is similar to Selective Laser Sintering. Both processes use a powder bed. SLS uses a laser to fuse the powder while MJF is a chemical process using a fusing agent.

MJF Material

| STANDARD MJF MATERIAL |

LEAD TIME | OPTIMAL QUANTITY |

MAXIMUM DIMENSIONS | SUGGESTED MINIMUM WALL THICKNESS |

FINISH & APPEARANCE |

ADVANTAGES & CONSIDERATIONS |

|---|---|---|---|---|---|---|

| Nylon 12 (Gray or Dyed Black) | 2+ Days | Prototypes, Low-Volume, Short-Run Production | 274mm x 370mm x 360mm | 1mm |

|

|

MJF Parts In As Soon As 2 Days // Get A Quote

Direct Metal Laser Sintering (DMLS) 3D Material

Metal 3D printing technology, also known as Direct Metal Laser Sintering (DMLS) and Direct Metal Laser Melting (DMLM) is a metal-based additive layer manufacturing technology.

DMLS allows designers and engineers to streamline the manufacturing process with precision metal prototypes and low-volume metal production parts. These types of parts would be impractical or cost prohibitive to machine in a conventional manner. Fathom creates metal parts using a fiber laser fired onto a metal plate, repeatedly adding layers of powdered metal and fusing them to previous layers. Additional post-processing is recommended even though the resulting part is accurate, with excellent surface quality and mechanical properties, immediately after manufacturing

How does DMLS technology work? A metal 3D printer uses a laser beam to melt layers of metal powder, 20 to 60 microns thick, on top of each other. Powdered metal is spread across the entire build platform and selectively melted to previous layers. This additive process allows metal parts to be grown out of a bed of powdered metal. The process is like other polymer-based 3D printers that use powder bed fusion, including Selective Laser Sintering and Multi Jet Fusion.

In-House Post-Processing / /

Fathom uses EOS and SLM build platforms.

| Material | Alloy Designation | Layers | Hardness | Advantages | Applications |

|---|---|---|---|---|---|

| Stainless Steel (PH1) | 15-5 PH, DIN 1.4540 & UNS S15500 | 20 or 40 Micron Layers | 30-35 HRC Built, Post Hardened to 40 HRC | High Hardness & Strength | Prototype & Production Parts |

| Stainless Steel (GP1) | 17-4, European 1.4542, German X5CrNiCuNb16-4 | 20 or 40 Micron Layers | 230 ± 20 HV1 Built, Ground & Polished to 250-400 HV1 | High Toughness & Ductility | Engineering Applications |

| Cobalt Chrome (MP1) | ISO 5832-4 & ASTM F75 | 20, 40 or 50 Micron Layers | 35-45 HRC Built | High Temperature Resistance | Turbines & Engine Parts |

| Maraging Steel (MS1) | 18% Ni Maraging 300, European 1.2709, German X3NiCoMoTi 18-9-5 | 20 or 40 Micron Layers | 33-37 HRC Built, Post Hardened to 50-56 HRC | Easily Machinable & Excellent Polishability | Injection Molding, Tooling, Conformal Cooling |

| Aluminium AlSi10Mg | Typical Casting Alloy | 30 Micron Layers | Approx 119 ± 5 HBW | Low Weight, Good Thermal Properties | Automotive, Racing |

| NickelAlloy IN718 | UNS N07718, AMS 5662, AMS 5664, W.Nr 2.4668, DIN NiCr19Fe19NbMo3 | 40 Micron Layers | 30 HRC Built, Post Hardened 47 HRC | Heat & Corrosion Resistant | Turbines, Rockets, Aerospace |

| Stainless Steel (316L) | ASTM F138 | 20 Micron Layers | 85 HRB | Corrosion & Pitting Resistant | Surgical Tools, Food & Chemical Plants |

| Titanium Ti-64* | ASTM F2924 | 30 or 60 Micron Layers | 320 ± 15 HV5 | Lightweight, High Strength, Corrosion Resistance | Aerospace, Motorsport Racing |

| Titanium Ti-64 ELI* | ASTM F136 Properties | 30 or 60 Micron Layers | 320 ± 15 HV5 | Corrosion Resistance, Biocompatibility |

Medical, Biomedical, Implants |

*Please contact an Expert@Fathommfg.com for more information

DMLS Parts In As Soon As 3 Days / / Get A Quote

Parts made using additive manufacturing can have the same look, feel, and finish as a product made with traditional manufacturing processes. Any finishing that may be required depends on the kind of additive manufacturing method used. Finishing may include / /

Fathom works with companies of all sizes, from medical to consumer products, electronics, automotive, aerospace, and more. Receive instant quotes and project cost calculation for rapid turnaround projects.

Additional Resources

Precision manufacturing

from coast to coast.

HEADQUARTERS //

1050 Walnut Ridge Drive

Hartland, WI 53029

877-328-4668

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

480-966-2300

CALIFORNIA

46758 Lakeview Blvd

Fremont, CA 94538

COLORADO

7770 Washington St.

Denver, CO 80229

303-288-6855

FLORIDA

14000 N.W. 58th Court

Miami Lakes, FL 33014

305-889-3280

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

815-385-7500

1401 Brummel Ave

Elk Grove, IL 60007

847-952-8088

MINNESOTA

13758 Johnson Street NE

Ham Lake, MN 55304

763-755-7575

NEW YORK

1920 Slaterville Rd.

Ithaca, NY 14850

607-277-7070

401 W. Shore Blvd.

Newark, NY 14513

315-331-7680

TEXAS

1513 Sam Bass Rd.

Round Rock, TX 78660

512-255-1477