Wire EDM

- Build Complex Parts with Tight Tolerances

- Precision Cutting of Tough Materials

- Cost-Effective Manufacturing Option

Get a Quote

Or Any of Our 25+ Manufacturing Processes

When Precision Matters,

Wire EDM is the Solution

Fine Details and Tighter Tolerances for Complex Designs

When you need to cut tough metals with precise tolerances, wire EDM cutting is a cost-effective solution. The hardness of the material has no effect on the cutting speed of this technology, which means it can cut a stack of metal plates at the same time as a single workpiece. That makes it surprisingly cost-effective.

Wire EDM // Get A Quote

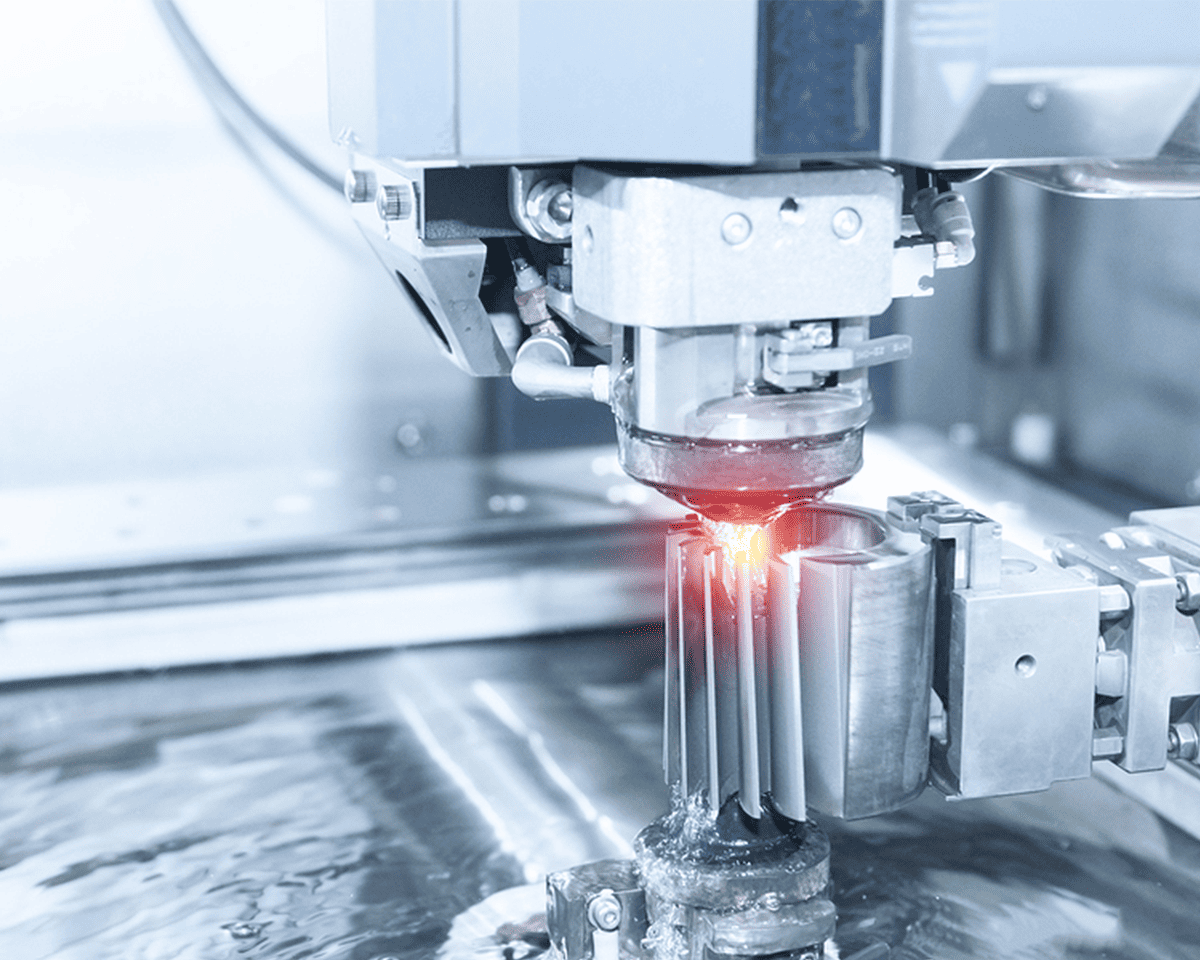

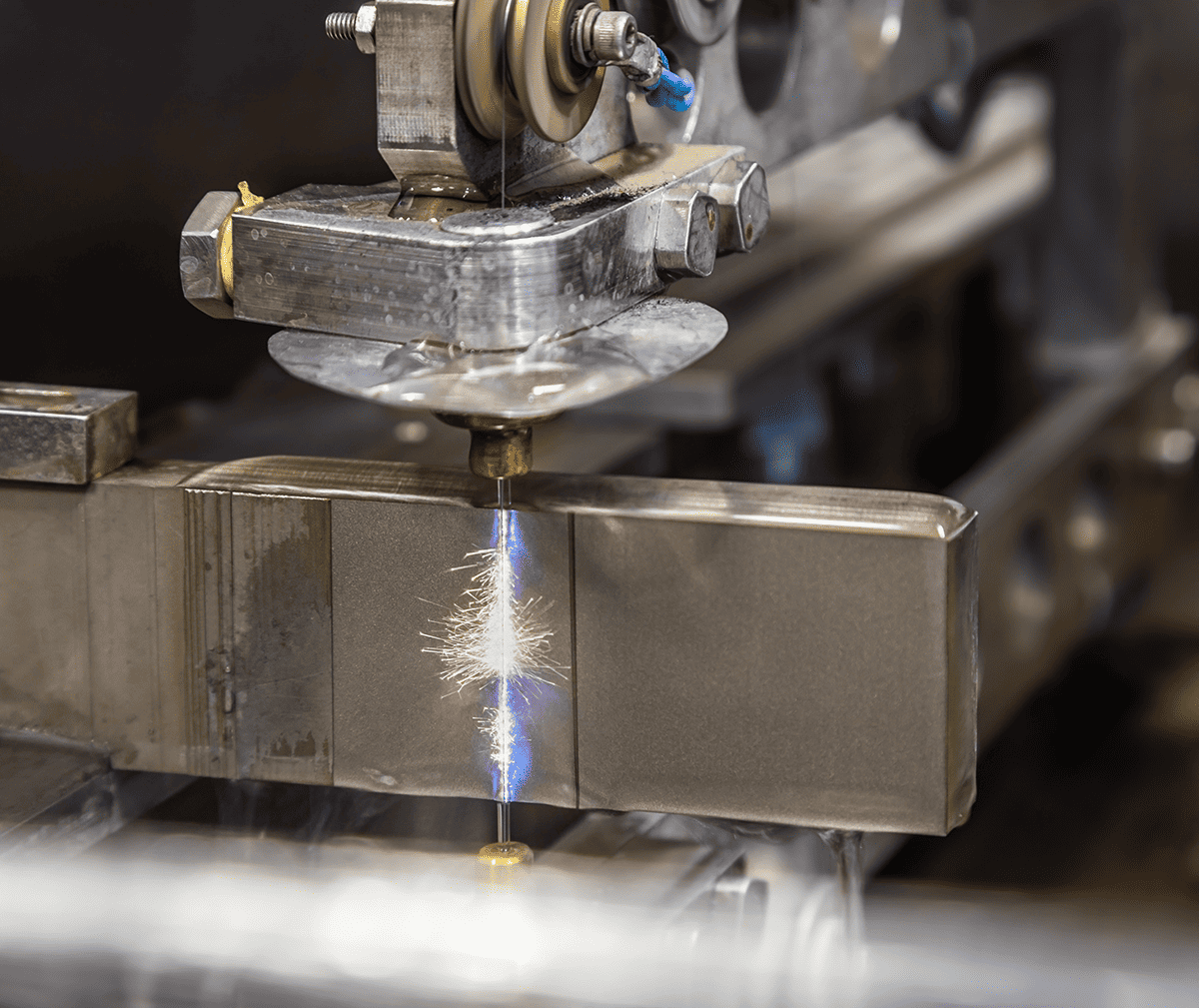

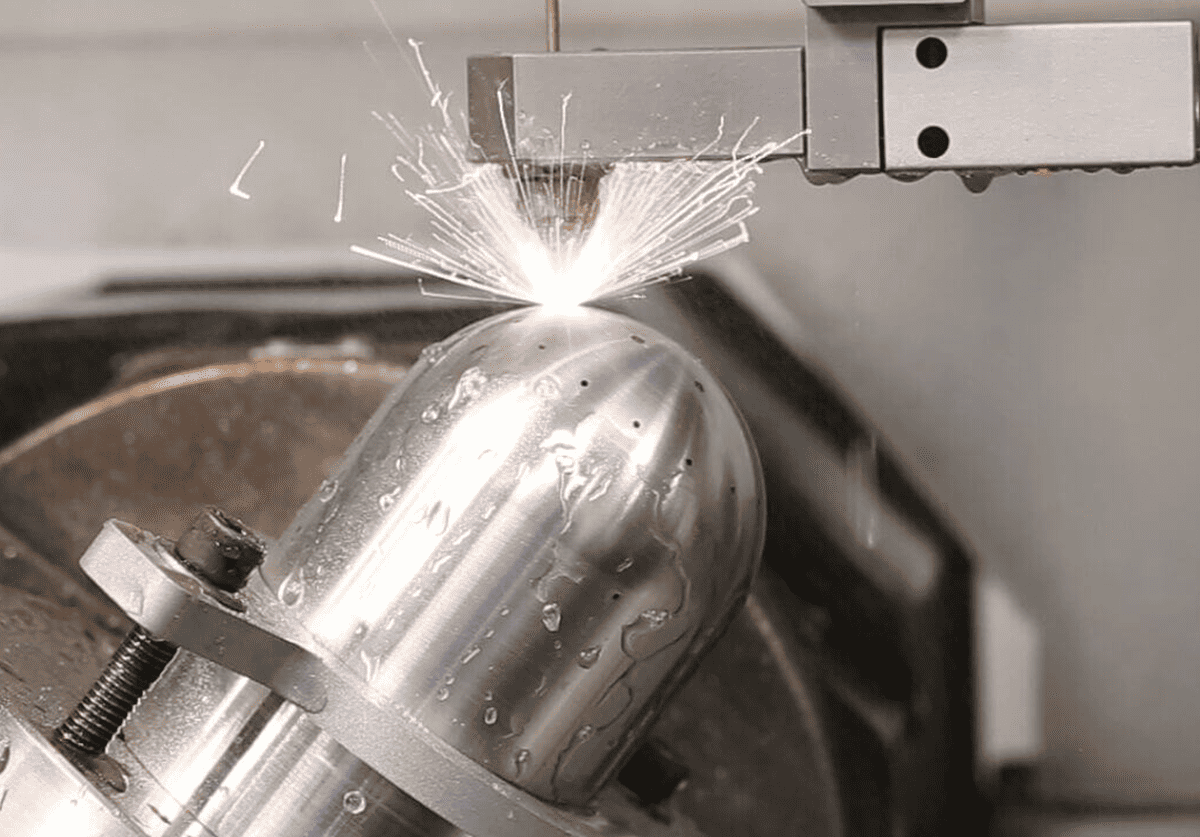

How Does Wire EDM Cutting Work?

Wire electrical discharge machining cuts a conductive metal with a thin electrode wire that follows a CNC-controlled path. The wire carries a high-voltage charge. The resulting spark melts the material adjacent to the wire, resulting in a very precise cut. A dielectric liquid, such as deionized water, cools the metal and flushes away melted metal particles. That also helps to minimize heat-affected areas.

Metal can be rough cut using wire EDM to a tolerance of .002 in. With trim passes, tolerance can be increased to .0002 in.

What Materials Can Be Processed Using Wire EDM?

Wire EDM can be used with any conductive metal, including:

- Copper

- Carbide

- Tungsten

- Bronze

- Carbon steel

- Inconel

- Stainless steel

- Hastelloy

- Kovar

- Titanium

- Carbon graphite

- High alloy steel

Advantages

Minimal Post-Processing Required // Wire EDM makes precise and accurate cuts, reducing the need for finishing and secondary processes. This makes it a very cost-effective cutting method.

Perfect for Parts With Complex Geometries // Wire EDM is ideal for creating complex designs that may be challenging to fabricate using other cutting techniques or CNC machining. It can also cut sharp corners with minimal radii.

Excellent Edge-Cut Quality // Wire EDM provides a clean vertical cut compared to water jet cutting, which tends to become less accurate toward the bottom of the cut, as the water jet begins to dissipate.

Wide Variety of Materials // Wire EDM can cut both tough and brittle metals without damaging them.

Efficient // Metal plates can be stacked to cut multiple workpieces in a single pass.

Disadvantages

Material Limitations // Wire EDM can only be used with metals that conduct electricity.

Not As Fast As Other Cutting Methods // Wire EDM cuts relatively slowly compared to water jet and microjet cutting.

Minimal Heat-Affected Zones // A narrow oxide or recast layer can develop along the cut. This can be reduced using trim passes. However, precise applications like aerospace may require electropolishing or passivation to remove it.

Experience Required // Wire EDM requires significant operator expertise and experience to do it well. Our staff has over 70 years of experience in producing parts using wire EDM.

Applications of Wire EDM Cutting

Wire EDM is equally well-suited to prototype and high-production parts, and industries like:

- Automotive

- Medical

- Aerospace

- Injection molding tools

Wire EDM Cutting Specifications

Wire EDM provides higher cutting accuracies and tighter tolerances than standard cutting processes:

- 5-Axis

- Wire diameter: .004~.012 in.

- Tolerance: .0001 in.

- Maximum taper angle: 30º @ 8 in. material thickness

- Position accuracy .0001 in. (.003mm)

- Feature and contour accuracy +/- .0001 in.

- Kerf width .006-.014 in.

- Maximum workpiece dimensions 27 x 40 in.

- Maximum workpiece thickness (may be stacked sheets) 15 in. thick

How Does Wire EDM Cutting Compare to Other Cutting Methods?

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

|---|---|---|---|---|---|---|---|

| WIRE EDM | 0.001″ – 15.0″ | 0.0001″ | 0.005″ | 1-High Volume | Low | 6-8 days | Conductive Metals |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| * CHEMICAL ETCHING | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

* Inner radius should be 100% of material thickness. Outer Radius should be 75% of material thickness.

**Dependent on geometry, volume and material: EXPEDITE options available.

Additional EDM Services Offered by Fathom

Sinker EDM // This type of EDM – also referred to as die sinking – is designed to create blind pockets, where a hole doesn’t go all the way through the material. The electrode is formed in the desired shape of the cavity to be created in the metal. The electrode is slowly lowered (or sunk) into the workpiece, eroding material until the cavity is created. Sinker EDM is used to create complex shapes, such as those needed for making molds, dies and other types of tooling.

Hole Popper EDM // A rotating tubular-shaped electrode is used to cut deep, small-diameter holes through the entire thickness of a conductive metal. It functions like a drill bit, except that an electrical spark is used to quickly and accurately cut these holes in the workpiece. This type of machine is sometimes used to create a starter hole for wire EDM to use to begin a cut.

Why Choose Fathom’s Wire EDM Service?

Accelerate Your Project with Wire EDM Cutting by Fathom

The Fathom team has extensive experience cutting parts with wire EDM and getting the highest quality results.

Our Tempe location is one of the premier shops for this technology in the U.S. and has been doing wire EDM cutting for over 20 years.

We do wire EDM cutting for customers in a variety of industries, including automotive, medical, aerospace, satellite, solar and firearms.

We have the capacity to handle your sheet metal fabrication and prototyping needs, large or small.