Contract Manufacturing Designed Around You

Every detail. Every tolerance. Every deadline. White-glove service tailored to your part, your specs, your urgency.

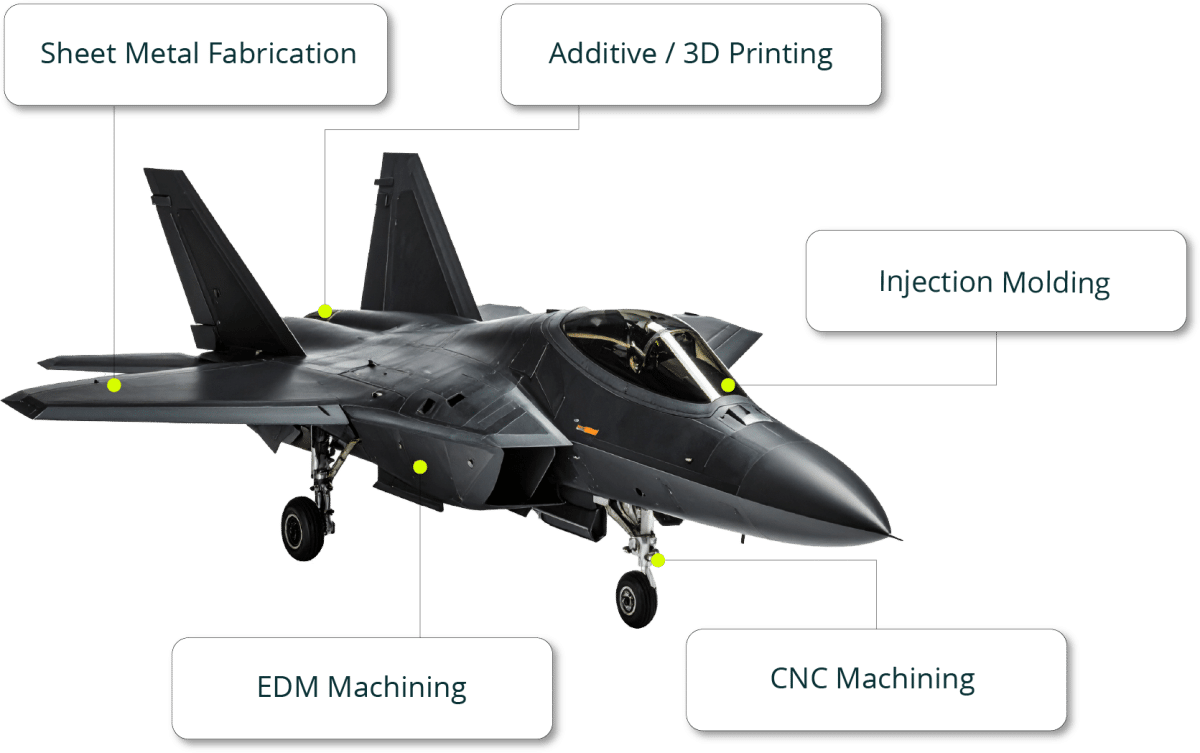

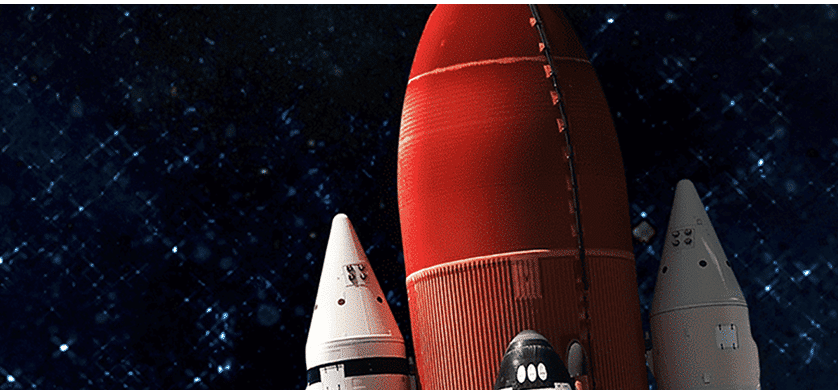

Aerospace & Defense

High-precision where performance and compliance matter most.

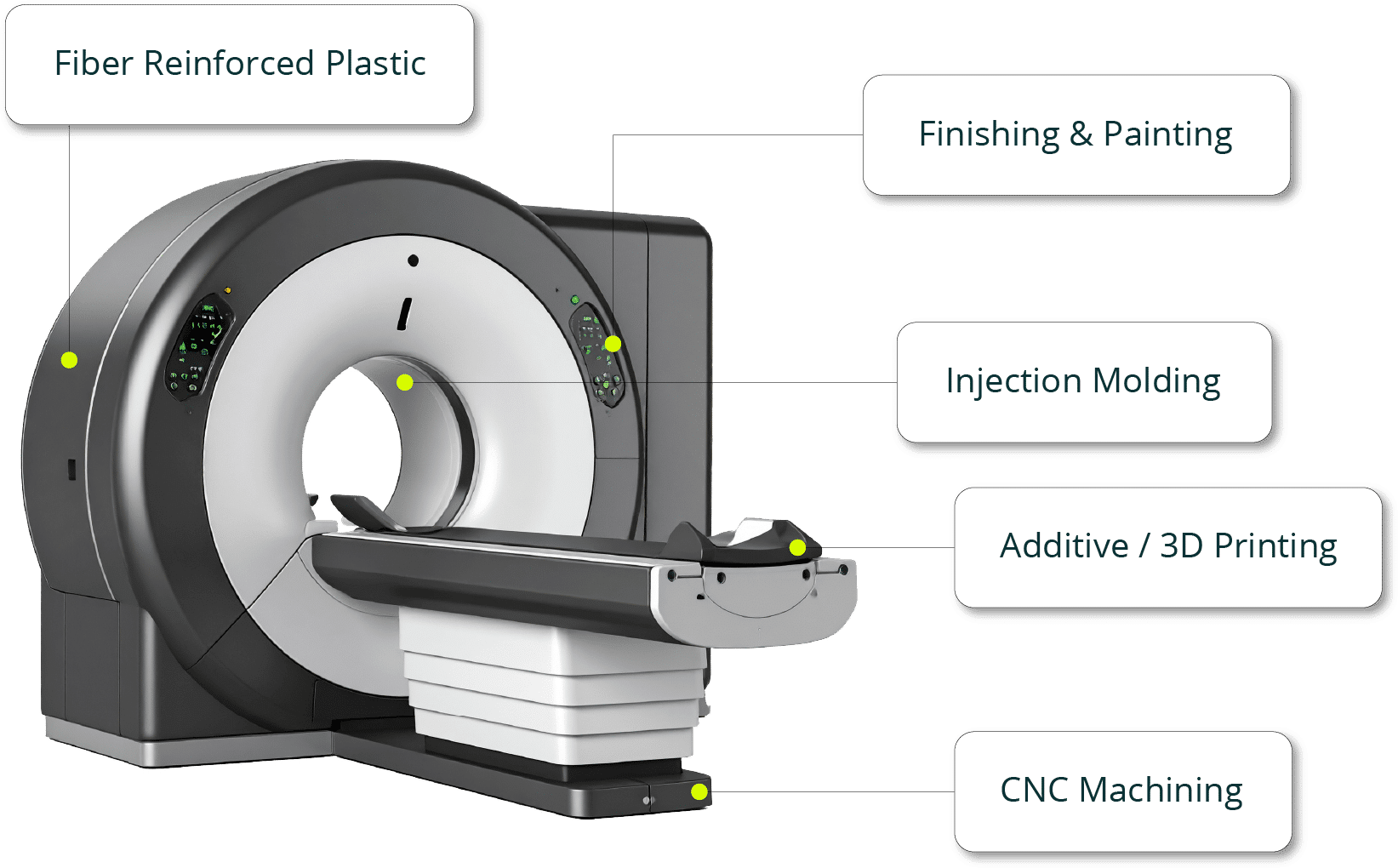

Medical

Quality controls for regulated environments.

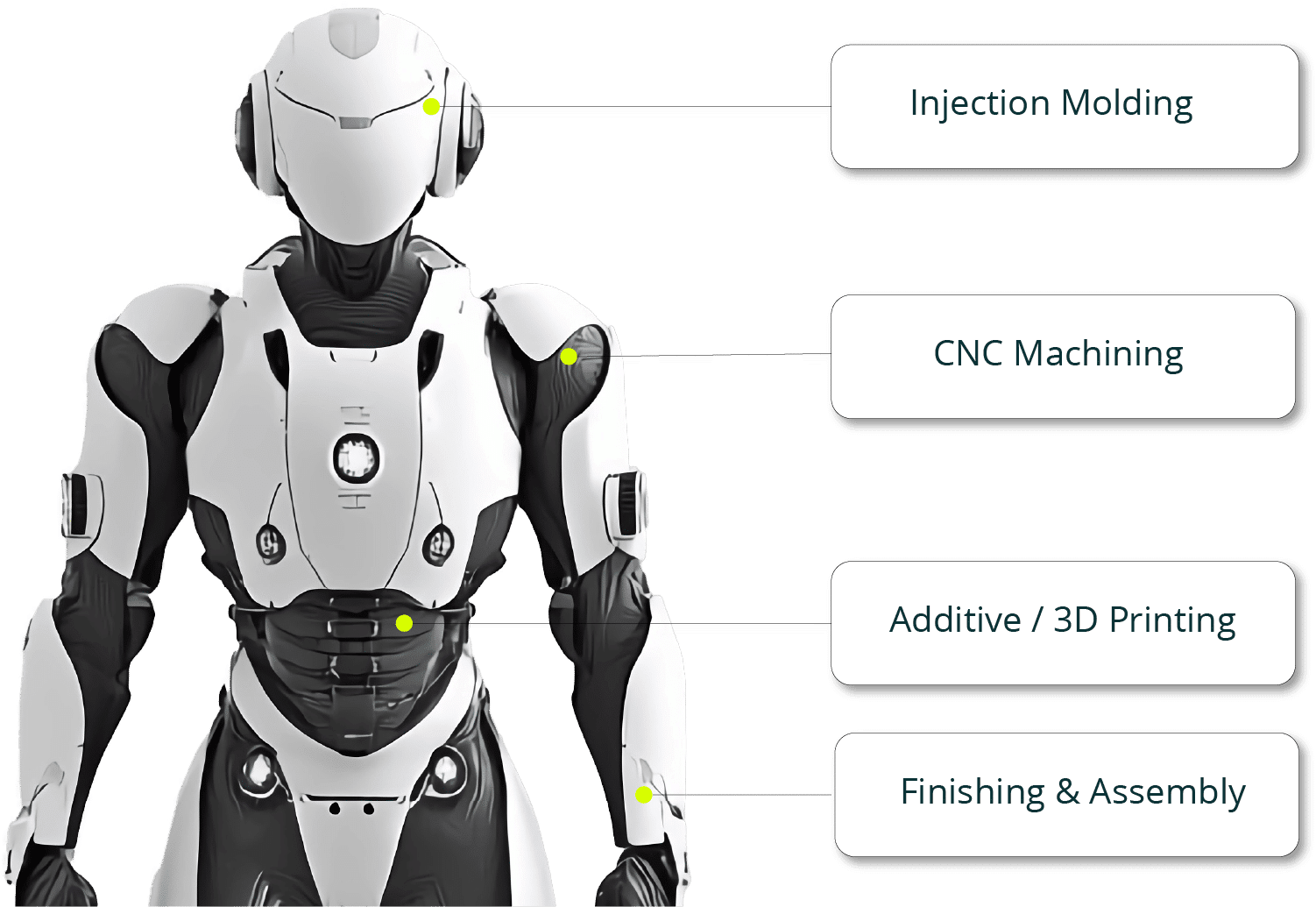

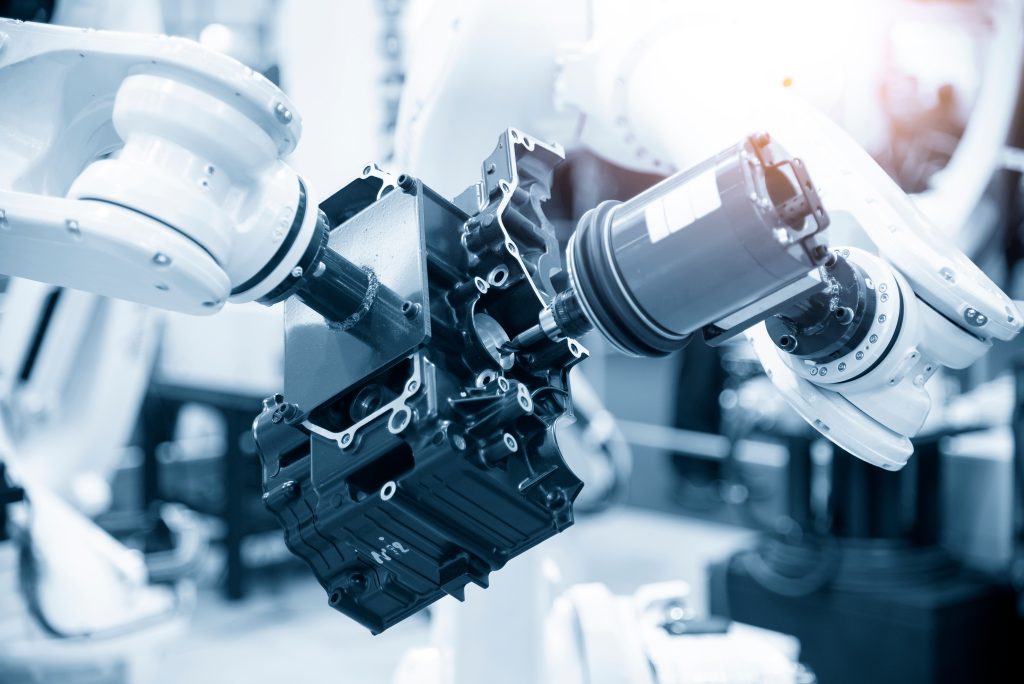

Automation & Robotics

For tight tolerances, reliability, and scale.

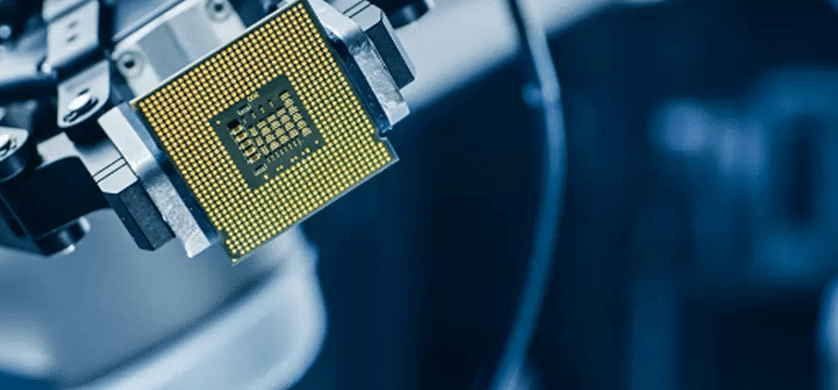

Semiconductor

The consistency and control for advanced fabrication.

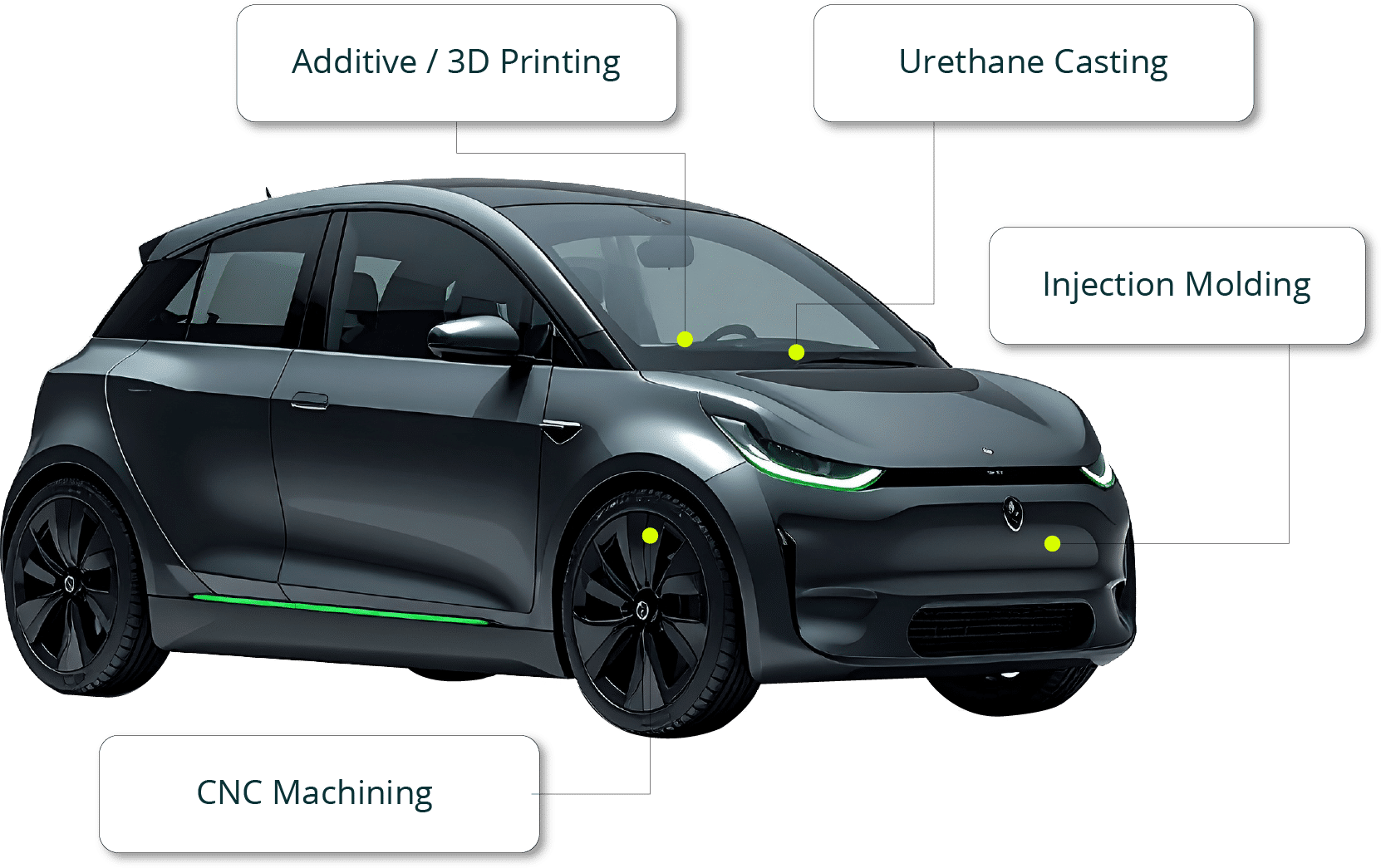

Automotive & EV

Precision for reliability, repeatability, and production readiness.

ICT & Energy

Accelerating ICT infrastructure builds with less risk—from prototype through ramp.

Trusted By Industry Leaders

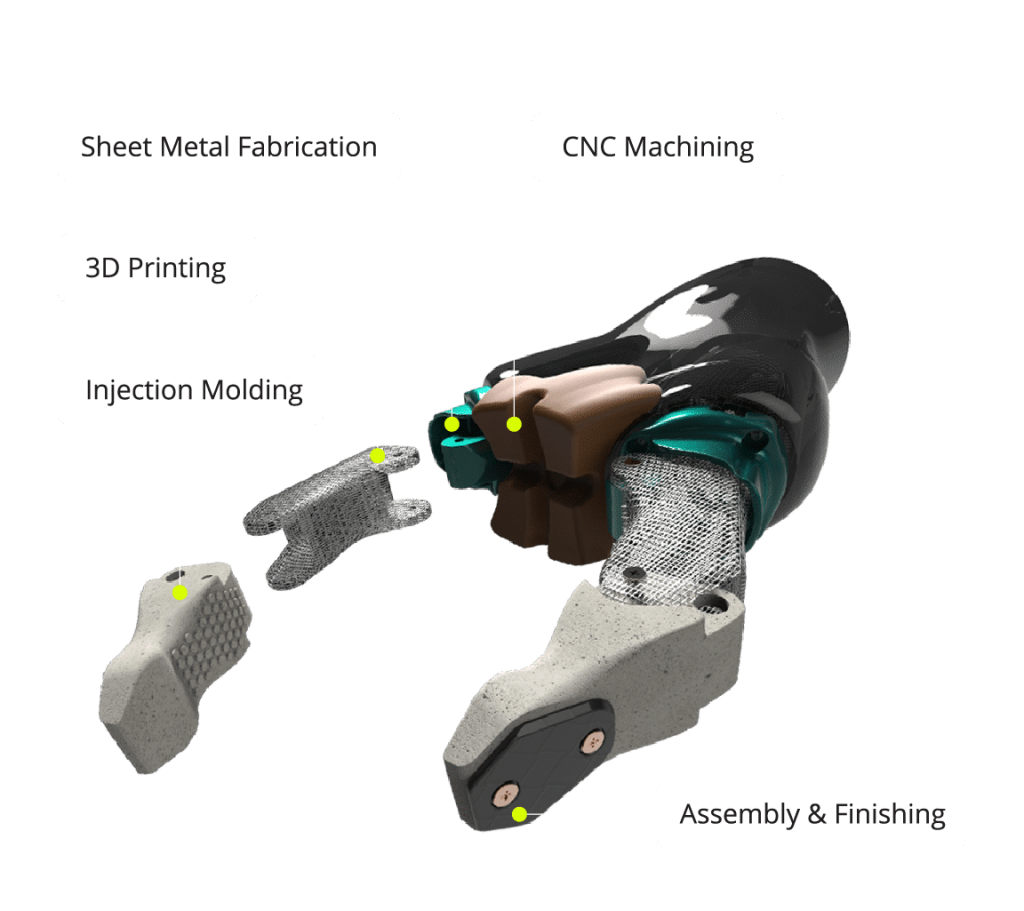

Precision Manufacturing, Speed & Scalability – All Under One Roof

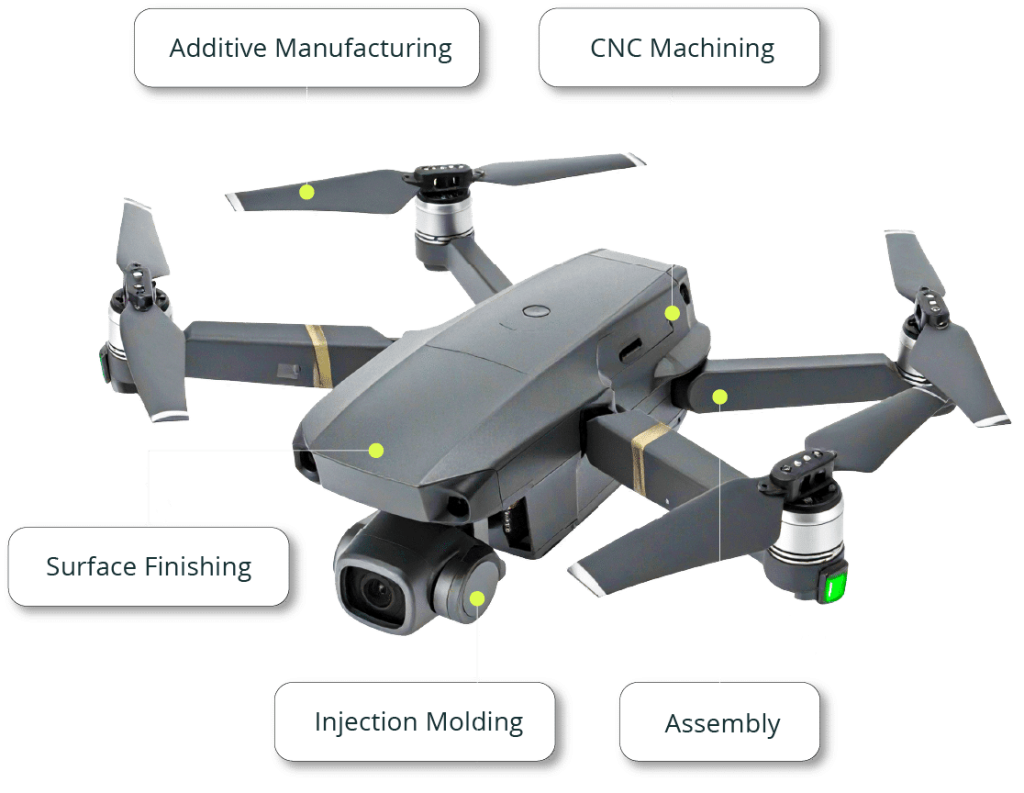

Leverage the industry’s most comprehensive suite of 25+ advanced manufacturing technologies – from CNC machining and 3D printing services to injection molding and sheet metal fabrication. No other contract manufacturer offers this breadth of capabilities, all backed by 250+ years of combined expertise. Whether your project demands rapid prototyping services, complex assemblies or high-volume production, Fathom has the precision manufacturing tools, talent and scale to deliver.

3D Printing Services

Whether you need prototype or production parts, we have an industrial 3D printing solution for you.

CNC Machining

Do you have unique machining needs? Complex part geometries? Tough materials? Extremely tight tolerances? We can handle it!

Metal Cutting & Forming

We bring unmatched ingenuity to your sheet metal fabrication challenges.

Molding

Options for all your molding needs, from urethane and RIM to injection and silicone molding.

Extrusion

When you need parts with continuous cross-sections like pipes, tubes or channels, we’ve got you covered.

Die Casting

When you need complex metal parts for high production needs, die casting is an excellent option.

Assembly & Finishing

Simplify your supply chain with file-to-finish services – all under one roof.

Inspection Services

We perform destructive and non-destructive testing in-house, saving you time and money.

Start Your Project with a Trusted Manufacturing Partner

Let’s Get Started on Your Project

Every quote is reviewed by an experienced engineer to ensure optimal design, materials and manufacturability, so your part gets made right, the first time.

Advanced engineering plus deep industry expertise is where the magic happens

Our deep industry expertise and commitment to human-first engineering enable us to efficiently move your ideas from concept to production. We’ll work with you every step of the way, providing you with advice and direction to bring your products to market – fast.

We’re engineers, manufacturers, and partners to the most innovative teams in the world.

We’re a company of tinkers, inventors and problem solvers. We love helping our customers!

6,300+

10,000+

20+

5,000+

25+

What it’s like to work with Fathom – in our customers’ words

We’re trusted by teams who need precision, speed and real manufacturing expertise.

Why Choose Fathom?

What Sets Us Apart? Services Tailored to Your Needs.

-

Comprehensive Capabilities

More advanced manufacturing capabilities than any other provider, with 25+ technologies backed by 250+ years of combined engineering and production expertise.

-

High-Touch Engineering Support

Real engineers, not just algorithms. Your dedicated project expert guides you every step, from concept to prototype to full production.

-

Smart Global Sourcing: Fathom Edgeworks

We deliver agile, expert-led global sourcing built to outmaneuver tariffs, navigate volatility, and keep production moving without compromise.

-

We’re Short-Run, High-Mix Experts

Some larger manufacturers prefer longer production runs. They tend to avoid short-run, high-mix projects. We welcome them. And we’re very good at it!

Who is Fathom?

Fathom exists to move manufacturing forward. We’re uniting the best of legacy craftsmanship with the possibilities of advanced technology to build what’s next. Born from a network of long-standing innovators, we believe in a more agile, responsive, and human approach to manufacturing, one that empowers engineers, fuels progress, and redefines what’s possible.

Join the Future of Manufacturing

At Fathom, we’re builders, crafting real parts with real impact. From cars and planes to medical breakthroughs and robotics, the work we do powers what’s next. We’re proud to be at the center of the digital manufacturing revolution, grounded in craftsmanship and driven by innovation.

We invest in our people through hands-on training, career growth, and a culture that celebrates progress. Building something great takes great people. If you’re ready to shape what’s next in manufacturing, we’d love to meet you.

We’re Organized to Accelerate

Your Time to Market

Our white-glove services can help you streamline and improve part procurement

Consulting Services

We’ll customize our services to ensure your projects are successful. We’re focused on building relationships, not instant, algorithm-based quotes.

Engineering & Design Support

Our engineers will help you optimize your designs for production and select the best material and finishing options to meet your needs.

Product Lifecycle

Fathom is uniquely organized to meet all your needs, from early concepts and prototypes to bridge and low-mid volume production.

Fathom Edgeworks

Fathom Edgeworks is how you get clarity, control and the best price for your overseas parts. We’ll beat any landed cost. Guaranteed.

Fathom is Your Product Lifecycle Partner

From early concepts and prototypes to bridge and low-volume production, we’ve got you covered.

Early Concept

We’ll perform a Design for Manufacturability (DFM) analysis to help you optimize your part design for production. Our expert engineers will also identify opportunities for cost reduction in part design, tooling and the proposed production process. Our ultimate goal? To eliminate potential production problems early in your design process.

Rapid Prototyping

Quickly iterate and finalize part designs using our on-demand manufacturing services. Rapid prototyping services employ digital manufacturing methods. They enable designs to move directly from a CAD drawing to a finished plastic or metal part in a matter of hours or days – without the need for tooling. Rapid prototyping can help you bring products to market faster.

Bridge Production

Bridge production can help you solve a number of common problems, including side-stepping tooling delays, meeting regulatory requirements and conducting market research if you’re unsure of demand for your new product. Producing a small quantity of parts enables you to preview a new product to a select audience and make tweaks before you ramp up to full production.

Small-Medium Volume Production

Many third-party manufacturers prefer to avoid low-volume production in favor of long production runs of relatively simple geometries. We specialize in low-volume/high-mix projects. We’re very good at it! Bridge production also makes sense when you’re moving tooling from overseas to domestic production, so you can keep your production line running smoothly.

Certifications: We’re Committed to Quality & Security

Certifications demonstrate that we maintain the highest quality standards – a must for our work in highly regulated industries.

Kick Off Your Project Today

Expect More From Contract Manufacturing

It’s time to level up your expectations. Contract manufacturing should be much more than an automated quote and superficial DFM feedback. Experience the Fathom white-glove difference – an engineering and expertise-driven process that will guide you from concept to production with clarity, confidence, and zero guesswork.