3D Printing Movie Props, Zero Theorem

North Design Labs worked with Fathom to quickly go from a concept to a fully functional 3D printed end-use movie prop within two weeks—from guidance on how to design for additive technologies to delivering parts overnight and everything in between.With only a couple weeks to take a concept to a fully functional prototype, we needed a company we could work closely with and I knew could deliver. Just as in the past, Fathom came through on all counts. I don’t even contact any other companies anymore because I know Fathom has and will always be the fastest! —Mike North, President of North Design Labs

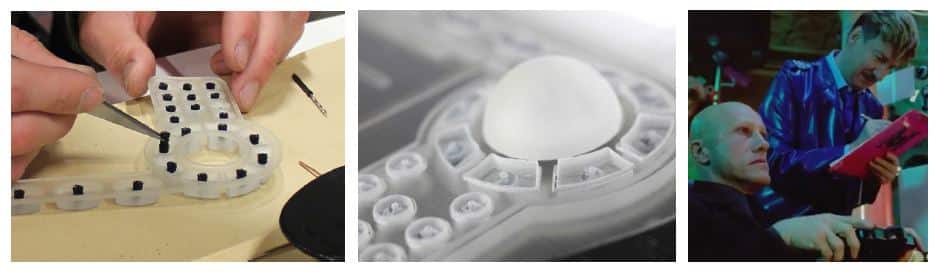

CHALLENGE: North Design Labs, LLC was working on a project for The Zero Theorem, a sci-fi movie directed by Terry Gilliam, when they came to Fathom in need of a highly detailed movie prop with a short lead-time. The team wanted to 3D print a functional, futuristic, interactive gadget to be used by actors in the film, a unique case that would house a Samsung Galaxy tablet. The design included movable tabs and buttons that would activate the touch screen, triggering various lights and graphics.

“The movie prop and controller presented a unique challenge by needing to not only look like some sort of alien futuristic device, but it also needed to function like one,” said North.

SOLUTION: Fathom provided guidance on how to prepare files for 3D printing to achieve the desired form, fit and functionality in PolyJet multi-materials. To complete the project in a timely manner, Fathom and North Design Labs utilized GrabCAD for file sharing during the iteration process.

The final design was 3D printed on the Objet500 Connex in VeroClear (rigid) and TangoBlackPlus (rubber-like) materials. The Fathom team also completed postprocessing and production assembly, including a critical step that involved adhering conductive foam to the underside of the keypad. This advanced application was 3D printed and assembled within two days (pictured with actor Christoph Waltz in the bottom, right image).

To get the PDF download of this 3D printing case study,