Guided by Fathom

Human-first manufacturing in action - from across our vast manufacturing network

Featured Post

12 Feb 2026

All Industries

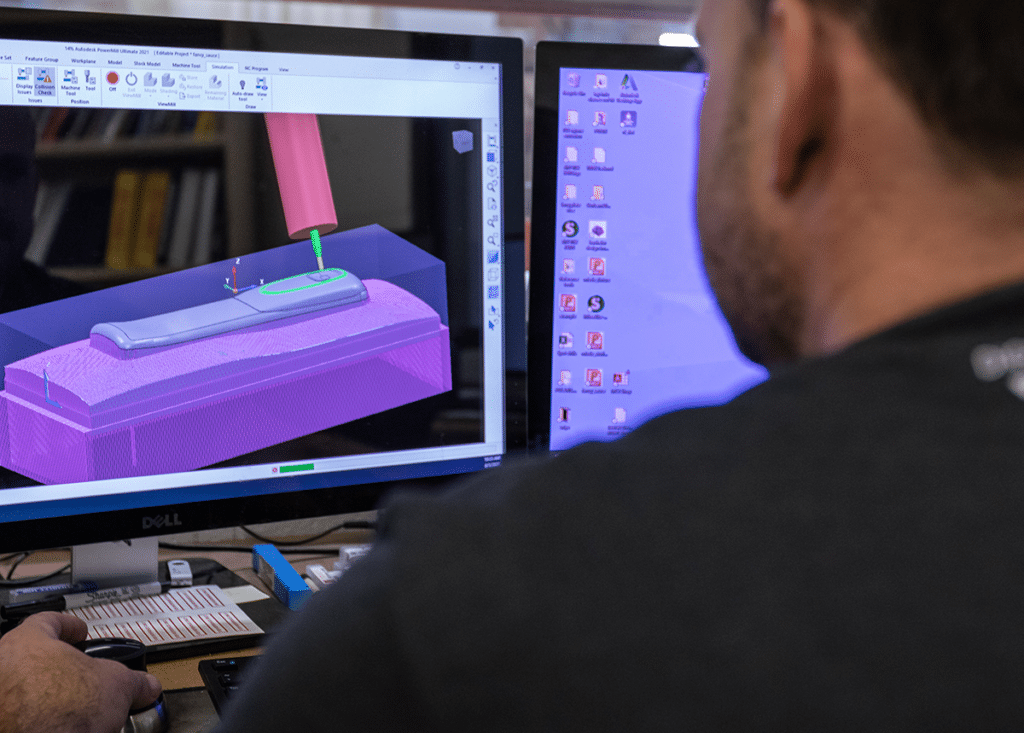

Engineering Design & Support

What White Glove Manufacturing Really Means at Fathom

Here's an inside look at how we're integrating white glove service into our operational DNA to transform the customer experience.

Learn MoreDon’t miss any of our thought-provoking blog posts. Sign up for our newsletter today.

Newsletter Form

"*" indicates required fields