Guided by Fathom

Human-first manufacturing in action - from across our vast manufacturing network

Featured Post

04 Mar 2026

All Industries

Assembly & Finishing

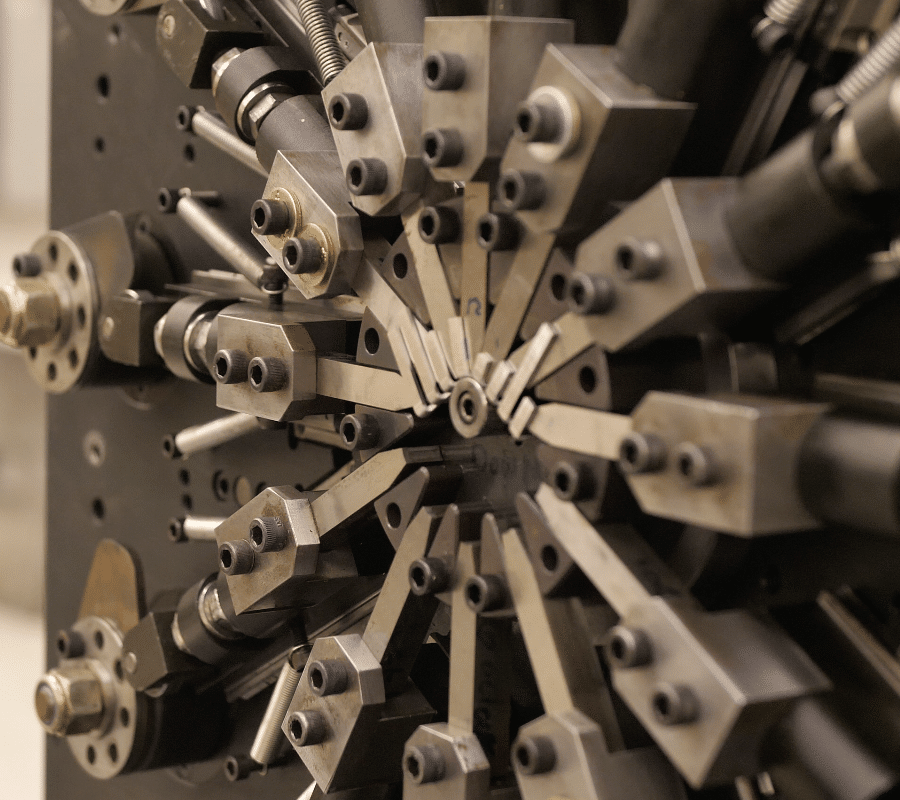

What Makes Incodema by Fathom the Go-To for “Impossible” Sheet Metal Fabrication?

Incodema by Fathom specializes in fabricating small, complex sheet metal parts that require a high level of skill and technology to produce. It has built a reputation that makes it stand out in a very competitive industry.

Learn MoreDon’t miss any of our thought-provoking blog posts. Sign up for our newsletter today.

Newsletter Form

"*" indicates required fields