Hartland, Wis., November 10, 2020

In 2020, four legacy companies – FATHOM, Midwest Composite Technologies, ICOMold and GPI Prototype – combined to form Fathom, the largest privately held digital manufacturing company in North America. As each held important industry positions individually, together they are uniquely poised to lead the digital manufacturing revolution. Moving forward, the companies will operate under the brand, Fathom.

To fully understand and best serve our consolidated customer base, Fathom underwent an independent consumer research study which unanimously recognized Fathom for its responsive communication, speed, agility, and expertise. “This is a pivotal moment in our industry to drive innovation and change, the new Fathom has been formed to drive a differentiated and impactful customer experience,” stated Rich Stump, Co-Founder and Chief Commercial Officer (CCO), Fathom. To simply be recognized is not enough – Fathom strives to be the absolute BEST at these important attributes which are critical to the success of its current and future customers.

Who is Fathom?

The future of manufacturing is changing and Fathom is leading that change by leveraging our proven differentiators to reimagine the customer experience. Built on Industry 4.0, Fathom is the development of enhanced solutions backed by 35 years of industry expertise. This enables Fathom to reimagine digital manufacturing by joining proven methodologies with new processes and technologies.

Fathom combines a broad array of advanced manufacturing technologies to provide a unique and impactful development process. We proactively push the boundaries of innovative solutions to turn concepts into reality. With clients ranging from industries within the Aerospace, Defense, Automotive, Technology, Medical & IOT sectors, Fathom’s digital manufacturing capabilities are now integral to their product development process.

“We are very excited to announce and begin executing our Fathom 4.0 strategy. This differentiated strategy focuses on speed, problem-solving, adaptive customer technical responsiveness and manufacturing to customers’ specifications (project complexity). All of this is backed by the industry’s most talented team and extensive capabilities. We believe this strategy will position Fathom as the most unique and differentiated digital manufacturer in North America.”— Ryan Martin, CEO, Fathom

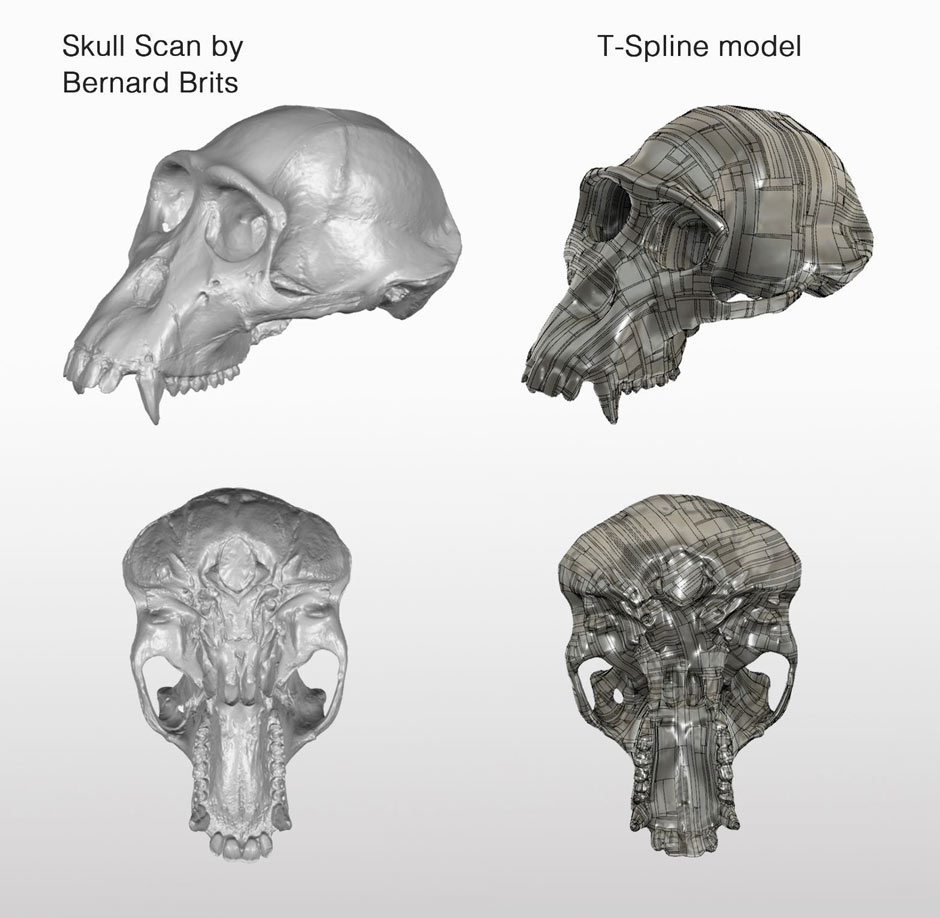

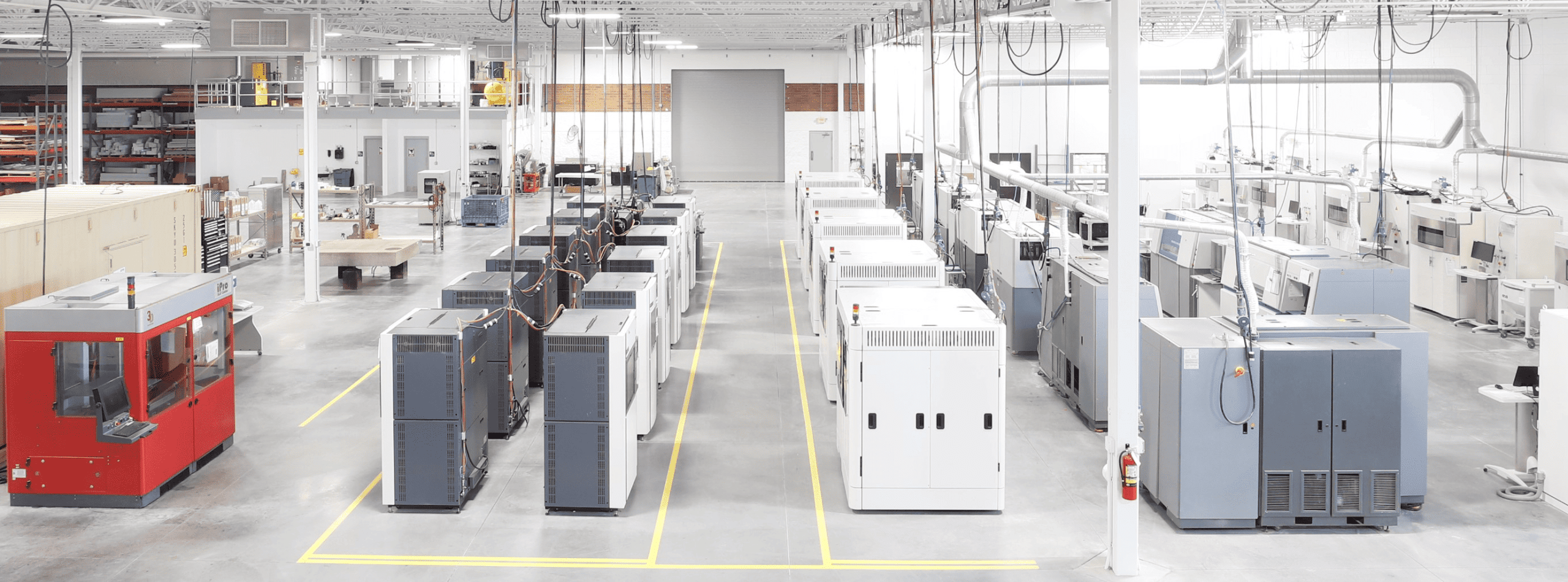

As experts in additive and traditional manufacturing, our in-depth expertise begins with a technology agnostic approach. This inventive approach is backed by over 200,000 square feet of manufacturing space where we utilize:

- 14 manufacturing production methods

- 6 additive manufacturing technologies

- Over 90 industrial grade / large format additive systems

- A combination of over 125 mills, lathes, presses & 3D printers

- Domestic CNC

- Urethane casting

- Domestic and International Injection Molding

- Enhanced model finishing and assembly

Working with Fathom provides immediate and comprehensive access to the most relevant equipment and experience in advanced manufacturing, engineering, and prototyping. We simply bring it all together, we boldly make the investments in our business and leverage our expertise to problem solve and deliver high-efficiency outcomes every time for our customers. See the new Fathom at fathommfg.com/wp/.