Fathom Acquires GPI Prototype & Manufacturing Services / / A Legacy Metal Additive Manufacturing Company

We’re delighted to announce that GPI Prototyping and Manufacturing Services (GPI) is now a part of Fathom.

Official Press Release / / Click Here

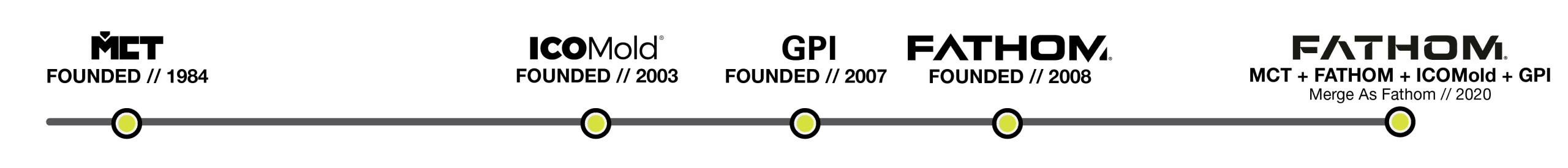

Midwest Composite Technologies acquired Fathom and ICOMold in 2019. With the GPI acquisition, all four companies will be moving forward under the Fathom brand. The combined company is positioned for growth as the leading privately held digital manufacturing company in the United States and now offers expanded manufacturing capabilities to all customers.

Founded in 2007 as one of the first metal additive manufacturing services providers in the country, GPI offers Direct Metal Laser Sintering (“DMLS”) additive manufacturing and CNC machining services, producing metal parts with complex geometries for on-demand manufacturing applications. Utilizing a variety of metals, including aluminum, stainless steel, tool steel, titanium, inconel and cobalt chrome, GPI works with Fortune 500 companies across medical, aerospace & defense, R&D and industrial end markets. The Company holds ISO 9001, ISO 13485 and AS9100D certifications and is ITAR registered.

GPI is now part of the largest privately held digital manufacturing service provider in North America.

“GPI’s ability to leverage metal additive manufacturing accelerates both design cycles and time to market and further enhances Fathom’s existing metal additive capabilities and our unique customer value proposition. We’re excited to work closely with GPI’s customers as a turnkey partner for on-demand manufacturing, providing a broad array of complementary services and an unparalleled customer experience.” / / Ryan Martin, Chief Executive Officer of Fathom

What does this acquisition mean for GPI customers?

This acquisition will give GPI customers access to a vast amount of additional manufacturing capabilities focused on technical expertise, speed, agility and complexity. We have 13 years of advanced manufacturing experience in metal additive and are looking forward to working with you on your next project or to answer any questions you may have about Fathom.

GPI customers will now have access to our in-house CNC machining, post-processing and finishing capabilities, in addition to the high-quality metal 3D printing you’ve grown to expect from GPI. You’ll find Fathom will fulfill your prototyping and manufacturing needs comprehensively and quickly.

With over three decades of experience manufacturing, we have thousands of materials ranging from plastics to polymers to composites and metals.

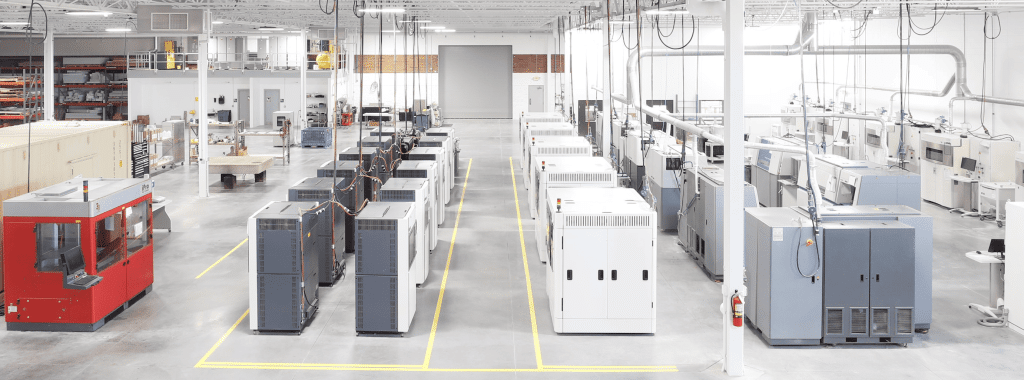

Who is Fathom? / / Fathom is the largest privately held service providers for rapid prototyping and on-demand additive manufacturing in North America. We are driven to create a differentiated customer experience driven by speed, complexity & agility to provide the most unique and impactful on-demand manufacturing in the industry.

Fathom Offers / /

- 14 manufacturing production methods

- 6 additive manufacturing technologies

- Over 90 industrial grade / large format additive systems

- A combination of over 125 mills, lathes, presses & 3D printers

- Domestic CNC

- Urethane casting

- Domestic and International Injection Molding

- Enhanced model finishing and assembly

Main Services Include—But Not Limited To / /

- Additive Manufacturing & 3D Printing / / SLS, PolyJet, FDM, SLA, MJF & DMLS

- 3 & 5 Axis CNC Machining

- Urethane Casting

- Injection Tooling & Molding

- Finishing & Assembly

What does the GPI acquisition mean for the company? / / With the recent acquisition of GPI Prototype and Manufacturing, Fathom has doubled its metal additive capacity creating a more encompassing DMLS solution for its customers.

DMLS materials to include / /

- Stainless Steel (PH1, GP1, 316L)

- Cobalt Chrome (MP1)

- Maraging Steel (MS1)

- Aluminum (AlSi10Mg)

- Nickel Alloy (IN718)

- Titanium (Ti-64, ELI)

- Inconel Alloy

In addition, we are adding Electrical Discharge Machining (EDM) capabilities, additional metallurgical analysis equipment and mechanical quality assurance – In-Process Quality Assurance (IPQA) activities.

Fathom holds ISO 9001 and AS9100 Rev D certifications and is ITAR registered