When you need complex formed sheet metal parts, two popular options for cutting a “blank” with precise profiles, holes and features are laser cutting and water jet cutting. But which one is best for your application?

This guide breaks down how each process works, where performance diverges (especially around heat-affected zones) and how to choose the best option based your design and production goals.

How Does Laser Cutting Work?

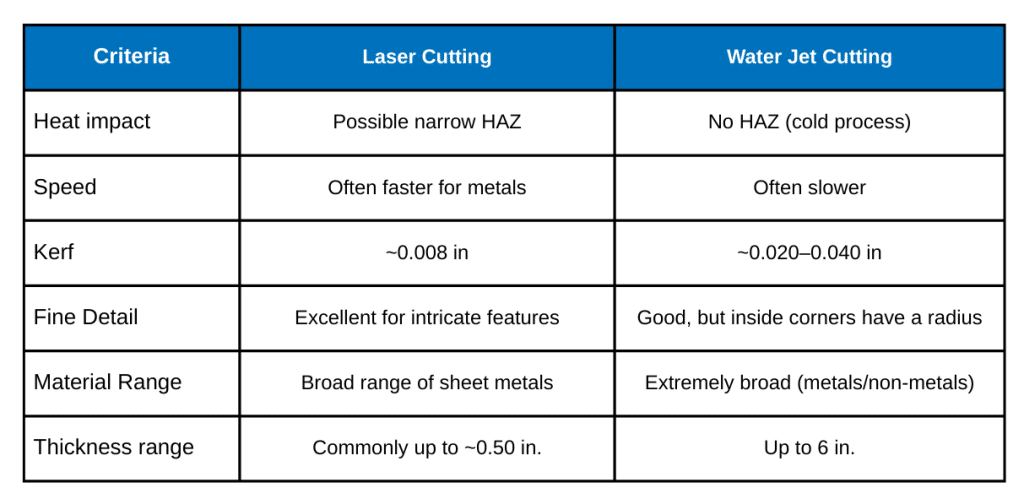

Laser cutting uses a CNC-controlled, high-powered laser beam to cut sheet metal. Its kerf is barely larger than the beam, which enables it to create fine geometries and intricate shapes with remarkable accuracy. You can also use laser cutting to etch or engrave parts, adding markings for part numbers or serial numbers to your parts.

Our laser cutting machines have a stated kerf width of ~0.008 in. and typical tolerance capability in the 0.002–0.005 in. range, depending upon on the material.

Materials: Laser cutting can be used to make blanks from a wide range of metals, including aluminum, carbon steel, stainless steel and copper.

Key Advantage: Laser cutting is typically faster than water jet cutting for many sheet metal jobs, especially thinner gauges and higher volumes. If you’re trying to maximize parts-per-hour on metal sheet work, laser cutting is frequently the way to go.

Key Disadvantage: Laser jet cutting can cause heat-affected edges along the cutting surface.

How Does Water Jet Cutting Work?

Water jet cutting uses an ultra-high-pressure stream of water, often mixed with an abrasive, to erode material along the cut path. Average kerf width is 0.02 in. at a tolerance of 0.005-0.015 in. It’s valued for excellent edge quality and for being a cold process – that is, one that doesn’t generate heat along the cutting surface. Material up to 6 in. thick can be cut using water jet cutting. That means it can cut multiple sheets of material at one time.

Micro water jet cutting tools, as their name implies, can make even more precise cuts. With a kerf width of only 0.009 in., it can maintain tolerances as low as 0.0005 in.

Materials: Water jet’s calling card is the exceptional range of materials it can cut. It can cut virtually any material, including metals and also non-metals like glass, plastic, stone, rubber, composites (Kevlar, carbon fiber) and ceramics, plus bonded/laminated materials.

Key Advantage: Water jet cutting doesn’t create thermal distortions or heat-affected edges.

Key Disadvantage: Water jet cutting is slower than laser cutting. But it more than makes up for this limitation by enabling you to cut stacks of metal plate up to 6 in. thick.

Heat-Affected Zones: The Critical Difference

The heat generated by laser cutting can create a narrow heat-affected zone (HAZ) along the cut edge. It may cause brittleness, oxidation or corrosion in this area and may require secondary operations like deburring, sanding or finishing to correct it.

Water jet cutting creates no heat-affected zone because it doesn’t rely on thermal energy to cut the metal.

If your part is susceptible to thermal distortion, needs a stable microstructure at the edge or you’re working with a heat-sensitive alloy condition, you should consider water jet cutting.

Kerf: More Important Than You May Realize

Kerf is the width of material removed by the cut. It affects dimensional accuracy, minimum feature size, tight corner behavior and nesting efficiency.

Laser cutters offer a narrow kerf averaging 0.008 in., which makes them well-suited for complex details. In contrast, water jets have a wider kerf, averaging 0.020–0.040 in. One limitation: they can’t create perfectly sharp inside corners and will leave a radius approximately equal to the jet width.

Managing the Trade-Offs Between Laser Jet & Water Jet Cutting

If you’re chasing small features, tight slots and high-density nests, laser kerf and corner performance are often the differentiators.

If you need excellent edges without thermal impact, and your geometry doesn’t rely on sharp internal corners, water jet cutting is a strong contender.

Comparison: Laser vs. Water Jet Cutting

Which Technology is Best For Your Project?

Choose laser cutting when:

- You need speed and throughput. If you’re optimizing lead time and parts-per-hour on metal sheets, laser cutting is usually the best fit.

- Your design has small features or tight nests. The narrow laser kerf supports finer geometry and efficient material utilization.

- Edge cleanup is usually minimal. Some burn mark cleanup may be required.

- You want etching or engraving performed at the same time as the blanks are cut. Lasers can add identifiers like part and serial numbers.

- Watch-outs: Heat-affected zones, edge oxidation on some alloys/finishes and thermal distortion risk on delicate geometries.

Choose water jet cutting when…

- Material properties at the edge are critical. No HAZ makes water jet cutting a major advantage for heat-sensitive parts.

- You’re cutting thicker sections or difficult materials. An abrasive water jet is built for hard/thick materials.

- You need broad material compatibility, especially if your BOM includes composites, laminates, or non-metals alongside metal components.

- You want clean cuts with reduced post-processing. Water jet’s edge quality and cold process can simplify post-processing.

- Watch-outs: Slower cutting speed, reduced accuracy as the thickness increases and inside corners that retain a radius.

The Bottom Line

Laser cutting and water jet cutting are both excellent at turning sheet stock into accurate parts, but they optimize for different priorities:

Laser jet cutting: Speed, fine detail, tight kerf and efficient production for common sheet metals.

Water jet cutting: No HAZ, broad material versatility and strong performance on thick/hard materials, at the cost of speed and sharp inside corners.

Do you have questions about your formed metal part designs? Talk to one of our experienced engineers.