These three factors would seem to be opposed to each other. As speed increases, precision and consistency often go down. But not at Centex by Fathom.

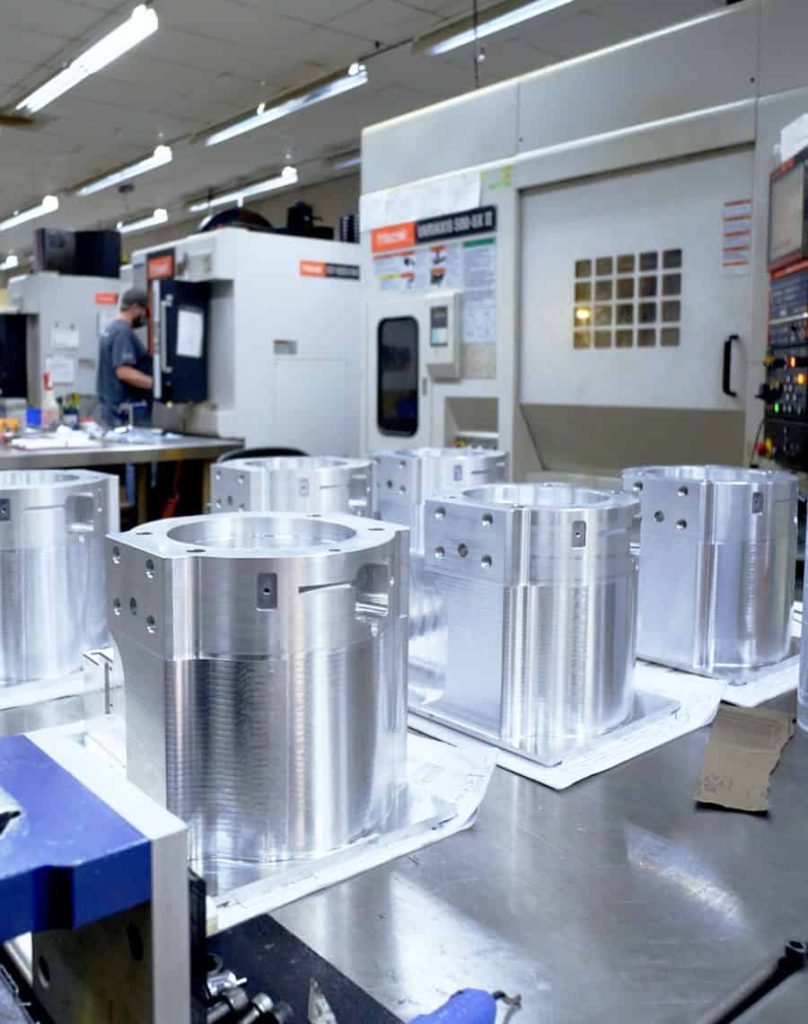

The leadership at Fathom’s facility in Austin knows the little things add up. An intense focus on the details has made it a go-to site for tight-tolerance CNC machining of medical parts for many years. Centex by Fathom proves it’s possible to deliver speedy turnarounds of complex parts and maintain full compliance –without compromise.

Let’s take a closer look at how its talented team delivers on this promise.

SPEED

The manufacturing process

While many businesses talk about eliminating a bottleneck, Centex talks about “feeding” it. That means ensuring that its milling centers – a key bottleneck – never sit idle. A great deal of attention and resources are devoted to improving and accelerating flow in this area.

- A comprehensive tool library improves the odds that its machinists will have quick access to the right cutter.

- Thorough tool setup sheets help reduce setup times for each job.

- Assistants, rather than machinists, usually access the tool library to speed the process, so the machinists can focus on machine setup.

Beyond the bottleneck, a purposeful facility design further enables a smooth yet rapid flow.

Updated software

Centex by Fathom recently upgraded its Enterprise Resource Planning system (ERP), a centralized software platform that manages and connects core operations across the company. With an ERP, there are no longer separate systems for accounting, inventory, production and purchasing. Instead, everything is integrated into a single platform that shares data in real time.

While an ERP is not unique to Centex by Fathom, a recent upgrade helps set it apart. New, highly advanced programming supports all phases of the process, including job planning and scheduling.

Faster turnaround of estimates

Speed applies not only to production, but also to how quickly a part moves through the quoting process and becomes ready for manufacturing. Customers appreciate Centex by Fathom’s attention to this part of the process, which also helps keep the bottleneck consistently fed. The goal is to “provide acceleration, compared with kinetic energy,” explains manufacturing engineer Trey Brown.

The estimating process proved to be a key opportunity for acceleration. Until recently, it took five days to develop a comprehensive quote. In the past, representatives from multiple teams gathered daily to review projects. This process tied up four or five key people for an hour each day. That was only the beginning, because those individuals then returned to their departments to process their part of each estimate.

Today, the ERP manages a largely paperless process. The software is advanced, but there is still real-world input from the seasoned Centex team.

As a result, quotes can now be turned around in 24 hours. Customers are happy and the daily meeting is no longer required. That frees up five staffers for a full hour every day. Under ideal circumstances, including having the proper materials on hand, quotes and parts have been turned around in as few as 72 hours.

COMPLIANCE

A long-term commitment to ISO 13485

When it comes to quality, you don’t have to take the Centex team’s word for it. The facility has been ISO 13485 certified for 20 years – an enormous achievement.

ISO 13485 is one of the most demanding quality standards in manufacturing because it governs medical devices, where failures can impact patient safety. Certification isn’t a one-time event, either. It requires continuous compliance, regular audits and proof of ongoing improvement. Many companies can achieve ISO 13485 once, but far fewer can maintain it long-term without lapses.

The ISO 13485 standard emphasizes risk management, traceability and process control across the entire product lifecycle, with a strong focus on:

- Documented procedures for every critical process

- Design controls and change management

- Risk analysis and mitigation

- Supplier qualification and monitoring

- Complete traceability of materials, processes and inspection records

- Corrective and preventive action (CAPA) systems

Companies must prove that they make quality parts and can do so consistently. They must catch problems early and prevent recurrences.

Achieving ISO 13485 typically involves extensive training and multiple internal and third-party audits. Once certified, companies must also undergo annual audits. Full recertification is required every three years.

Holding ISO 13485 certification for two decades means Centex by Fathom has:

- Passed dozens of external audits (not to mention internal)

- Maintained discipline through staff changes, new products and evolving regulations

- Kept documentation and processes aligned with changing standards

- Sustained a quality-first culture, not just a compliance checkbox

CMMs and quality planning

Centex’s facility layout supports efficient inspection and feedback, which are essential to quality.

Coordinate Measuring Machines (CMMs) ensure parts match their designs accurately, repeatably and with documented results. At Centex, milling centers and the quality department – including its CMMs – are located adjacent to the machining area, allowing parts to move quickly from cutting to inspection.

Beyond layout, the focus is on improving the quality planning process. In the past, quality plans were a mix of digital and printed documents, creating unnecessary handoffs and redundancies.

Updated processes have streamlined and fully digitized the quality workflow, making it easier to use and eliminating duplication. CMM output data is consolidated into a single, job-specific system, allowing all inspection results to be accessed in one place.

This integration improves speed, traceability and decision-making. It allows teams to quickly evaluate results, drive corrective actions and maintain high-quality performance, without slowing production.

Validation

Centex’s validation process consistently delivers final quality with rejection rates well below 1 percent, often measured in tenths of a percent.

- Before committing to full production, the team validates the first part to confirm the program, setup and process meet all quality requirements.

- This initial validation serves as the primary checkpoint before scaling up.

- The second (or third or fourth, and so on) runs go through the same validation as the first.

- Even then, the team revalidates setups, documentation and execution to ensure nothing has changed and everything is being done correctly.

Conclusion

At Centex by Fathom, speed is engineered, not rushed. And compliance is embedded during the process instead of being reviewed after the fact. The result is a manufacturing operation where precision, throughput and regulatory discipline work together to deliver consistent results for medical customers.