What is 5-axis machining? Let’s start with a simple analogy and then apply it to this sophisticated type of machining tool. We’ll also take a close look at the types of parts that it can produce and the industries that benefit most from it.

3-Axis Machining

Imagine placing a kitchen cutting board flat on a table. It’s clamped to the table so it can’t move. Then picture a cutting tool, such as a router, passing over It to make cuts in it. The cutting head has three directions of movement:

- Front to back

- Side to side

- Up and down

The cutting board itself cannot move. No lifting or tilting is allowed. That means the cutting tool can only machine the top of the cutting board.

To complete the machining process, you must inspect the board, flip it and re-secure it to the table. The other side is then machined, followed by an inspection.

4-axis machining

In the first example, once the cutting board was attached to the table, it couldn’t move. A 4-axis machine introduces rotation. Imagine standing the cutting board sideways and giving it the ability to rotate on the x-axis.

The cutting tool can still only move in three directions, as before. But the board can now be rotated, which means it can now machine the top and sides in a single setup. However, the board must still be flipped and reset on the turntable to machine its bottom surface.

5-Axis Machining

This type of machining introduces full freedom of movement. In addition to everything you can do with 3- and 4-axis machining, imagine you can lift the cutting board and tilt it in virtually any direction.

Imagine holding the board in your right hand. The cutting tools reach nearly the entire surface – except for the small area where your hand grips the part. For projects like this, our Centex by Fathom location completes all 5-axis operations and then transfers the part in a 3-axis mill to finish the part.

Let’s Apply What We’ve Learned

Of course, we’re not machining cutting boards. In the workplace, a solid block of material called the “workpiece” is secured inside a machining center using a “work holding” fixture. A rotating cutting tool, mounted in a spindle, removes material to shape the part.

3-axis machining moves the cutting tool along the X, Y and Z axes. The workpiece must be manually repositioned to provide access to all the part’s faces. That can introduce tolerance issues. That’s why 5-axis machines are preferred for holding tolerances and datum structures that can’t be machined in one 3-axis setup. Otherwise, with 3-axis machining, multiple setups and precision fixturing would be needed.

4-axis machining adds rotation, allowing side features to be milled without resetting the part. However, machining the bottom of the workpiece still requires repositioning.

5-axis machining adds two additional rotational axes (A and B), allowing the cutting tool to approach the workpiece from almost any angle. The cutting tool and the workpiece can move at the same time, too. This enables complex geometries, smooth curves and angled features.

Most significantly, it can do all of this without manually repositioning the part. When machining parts that require complex features and tight tolerances, that’s a very good thing!

What about machining the area where the part is held? 5-axis machining reorients the part by rotating it on two controlled axes, allowing the cutter to reach surfaces – including the “bottom” – without ever removing the part from the machine.

Advantages of 5-Axis Machining

5-axis machining is the part designer’s best friend. Parts can be milled, drilled and shaped at virtually any angle. “Designers have innumerable options if they know the part is going on 5-axis machine. With 3- and 4-axis, not so much,” explains Fathom Manufacturing Engineer Trey Brown.

5-axis machining is particularly well-suited for parts with features on the sides or at compound angles. On a 3-axis machine, these features would require repeated re-orientation of the part, which may make the process impractical.

Another key advantage of 5-axis machining is precision. The workpiece requires a single setup, which allows datums to be maintained throughout the process. This ensures accurate tolerances, hole locations, slots and precise locations of other features.

Efficiency is also a major benefit. A 5-axis job can often be completed with:

- One setup

- One continuous machining cycle

- One inspection

By contrast, 3- and 4-axis machining typically requires machining, inspection, resetting and reinspection – sometimes multiple times. That results in longer per-part cycles and significantly more labor.

Disadvantages of 5-Axis Machining

These machines are more complex and require more experienced people to program and operate them. They also take more time to set up and are more expensive to operate.

Also, parts machined on 5-axis equipment often need to be thick enough to be gripped securely. Long parts can be challenging. Often, the 5-axis machine will hold a part at an angle normal to the feature to be machined. The only way to reach it would be with an extended-length tool holder to remain clear of the part geometry. This can result in reduced tool rigidity, which in turn can lead to poor finishes, tolerance issues, or tool breakage.

Three- or 4-axis machines are more cost-effective for producing simple parts. These machines are less complex and tend to be less costly to run. While a 5-axis machine can produce anything a 3- or 4-axis machine can, it’s often not cost-effective for basic work.

What Types of Parts are Typically Produced Using 5-Axis Machining?

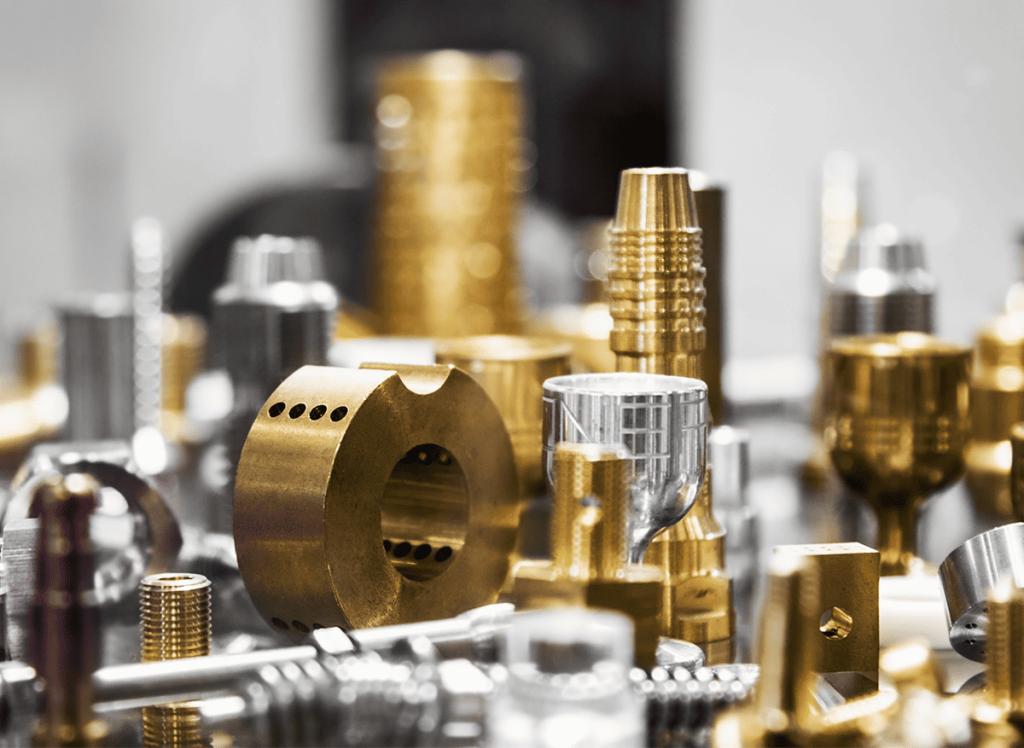

A wide range of materials can be machined using 5-axis equipment, including stainless steel, titanium and many plastics.

Common applications include:

- Semiconductor components, which often feature angled holes and complex geometries

- Medical devices, especially implants, where precision and smooth surfaces are critical

- High-performance aerospace parts, such as turbine blades and fuselage components.

- Automotive parts, including rugged, complex components for engines, transmissions and steering systems.

5-Axis Machining: The Workhorse of Modern Milling

In short, 5-axis machining delivers exceptional flexibility, accuracy and efficiency. It enables complex parts to be completed in a single, continuous setup while maintaining tight tolerances. It may be unnecessary for simple components, but it is invaluable when design freedom and precision matter most.