White-glove service is becoming one of the most used buzzwords in manufacturing. It’s showing up in sales decks, on websites and in pitches, often without much explanation of what it actually delivers for engineers and procurement teams under pressure. For many OEMs, the term lacks clarity.

At Fathom, “white glove manufacturing and engineering” is not a tagline or marketing strategy. It is a deliberate operating model designed to solve the most common frustrations OEMs experience when working with manufacturing partners; frustrations that slow projects down, introduce risk, and make already demanding jobs harder than they need to be.

According to Kim White, Vice President of Partner Operations and Customer Experience, those frustrations are remarkably consistent across industries, company size, and program type.

The Real Pain Points OEMs Bring to the Table

When OEMs arrive at Fathom, White says they are often carrying baggage from previous manufacturing relationships. Too many handoffs. Too many people are involved, with no clear owner. Too little transparency about what is happening between the moment an order is placed and the moment parts arrive.

Engineers and procurement teams often describe the supplier experience as feeding a vending machine: money goes in, a button is pushed, and parts eventually come out. Everything in between feels opaque. Once that button is pressed, there is little a customer can do to influence the outcome. There’s no clear visibility into progress, no obvious expert to engage, and no reliable way to course-correct.

This lack of transparency creates stress, particularly on complex programs with tight timelines, where internal stakeholders are demanding updates that suppliers cannot clearly or confidently provide.

The breakdown often begins earlier than many suppliers realize. White points to quoting as a common failure point. Speed-to-quote has become a competitive race, fueled by instant-quote marketplaces and automation. But speed alone does not help engineers or buyers explain why a project matters, what risks exist, or how decisions made early will affect outcomes later.

OEMs are not just looking for fast quotes. They are looking for partners who understand the “why” behind a project and can apply that context to engineering, pricing, manufacturing approach, and communication. Without that understanding, even the fastest quote can lead to downstream issues and disappointed customers.

Why Fathom Formalized a White-Glove Approach

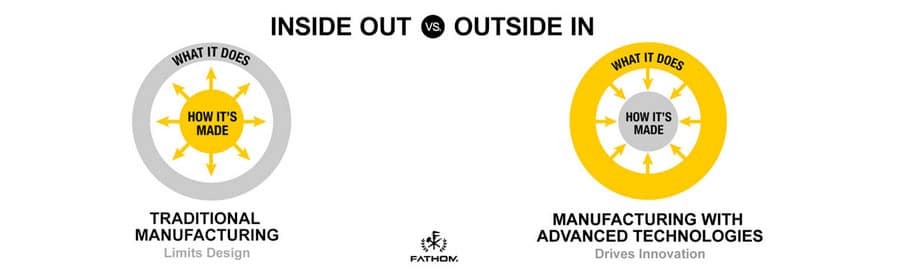

Fathom’s decision to formalize white-glove manufacturing and engineering was not driven by branding. It was driven by a clear realization: the company did not want to operate like a transactional manufacturing marketplace.

White describes an intentional shift away from one-size-fits-all workflows. Fathom invested time mapping how work, people, and information move through its system. The goal was to reduce unnecessary handoffs from the customer’s perspective while preserving the technical rigor required inside the manufacturing centers.

From the outside, customers experience fewer points of contact and a clear advocate who owns the delivery end-to-end. Internally, engineering, DFM, applications and manufacturing teams still collaborate deeply. The difference is that customers always know who is accountable for making everything come together.

That accountability is central to the white glove model. Customers do not have to guess who to call when something changes, a risk emerges, or priorities shift. There is a single point of ownership responsible for coordinating the response.

Quoting with Context, Not Guesswork

One of the most tangible ways white glove shows up is in Fathom’s quoting process. Instead of treating every quote equally, Fathom categorizes incoming requests by complexity. Low-complexity quotes can be turned around quickly, sometimes the same day. More complex, production-oriented programs receive the time and engineering attention they require.

More importantly, Fathom builds customer personas and quoting personas through structured design sessions. These conversations clarify what matters most to each customer: speed, cost targets, engineering collaboration, risk mitigation, or a balanced mix of all three.

That persona then follows the customer through the system. Estimators and application engineers know exactly which priorities to optimize, eliminating guesswork and reducing friction for procurement teams already managing an overwhelming volume of quotes.

For OEMs, the result is fewer surprises and quotes that actually reflect how decisions will be evaluated internally.

Radical Transparency & Fewer Surprises

White glove manufacturing does not eliminate risk. Custom manufacturing will always involve uncertainty. What it can eliminate is the shock that comes from finding out about problems too late.

White describes Fathom’s approach as radical transparency. Teams are encouraged to “look around the bend” and communicate potential risks early, even when those conversations are uncomfortable. Customers are brought into the problem-solving process instead of being shielded from it.

For many OEMs, this is one of the most valuable aspects of the white glove experience. The hardest part of their job is not managing delays; it is explaining those delays to their own customers and leadership after the fact. Proactive communication allows them to plan, adjust, and maintain credibility internally.

Tailoring White Glove to the Program, Not the Slogan

White glove service cannot look the same for every customer. Fathom tailors its approach based on industry, program complexity, and stage of development.

The company embeds experts with deep experience in specific verticals, rather than spreading generalists thinly across every market. That specialization allows teams to anticipate challenges unique to aerospace, medical, robotics, automotive, and other sectors Fathom serves.

For complex programs with multiple parts, sites, and timelines, customers are assigned experienced program managers who serve as a single point of contact across locations. Engineers and buyers do not have to chase updates from multiple facilities or stakeholders. Ownership stays centralized, even as execution spans the organization.

Making Engineers & Procurement Teams Look Good

When white glove manufacturing works the way it should, success is not measured by praise alone. It is measured by reduced friction and reclaimed time.

White describes success as giving customers back hours in their day by removing stress, uncertainty, and unnecessary coordination. Engineers can stay focused on design instead of firefighting. Procurement teams can manage their workload with confidence, rather than constantly following up on status.

Post-project reviews play a critical role. Even when a project is delivered on time and on spec, Fathom teams review what could be improved. Material choices, tolerances, and processes are evaluated and documented to enable the next iteration to be faster, cheaper, or more reliable.

Those insights are fed back into the quoting engine, creating a closed-loop system that improves with every project. Customers benefit from lessons learned without having to relearn them themselves.

When White Glove is the Right Fit

Not every program requires a white-glove approach. Simple, high-volume parts may be well served by transactional workflows. White-glove service becomes essential as complexity increases.

Multiple touchpoints, tight tolerances, regulatory requirements, or high internal visibility all signal the need for a deeper partnership. At that point, a purely transactional supplier relationship stops being sufficient.

Fathom’s model allows customers to blend approaches. High-complexity work receives high-touch support, while transactional work continues to move efficiently through streamlined systems. The experience remains consistent without applying unnecessary overhead.

Becoming Indispensable

When asked to sum up white glove manufacturing in one word, White chose “indispensable.”

Indispensability is earned by anticipating problems, identifying inefficiencies others miss, and helping customers succeed not just operationally, but professionally. It is the difference between delivering parts and delivering confidence. When we do this well, we become deeply embedded in our customers’ workflows—making it difficult for them to operate without us, not because of dependency, but because of the value, trust, and clarity we consistently provide.

For OEMs navigating increasingly complex manufacturing environments, white-glove engineering and manufacturing is not about being pampered. It is about having a partner who understands the stakes, owns the outcome, and makes the work easier—not harder.

Experience white glove service in action – request a quote.