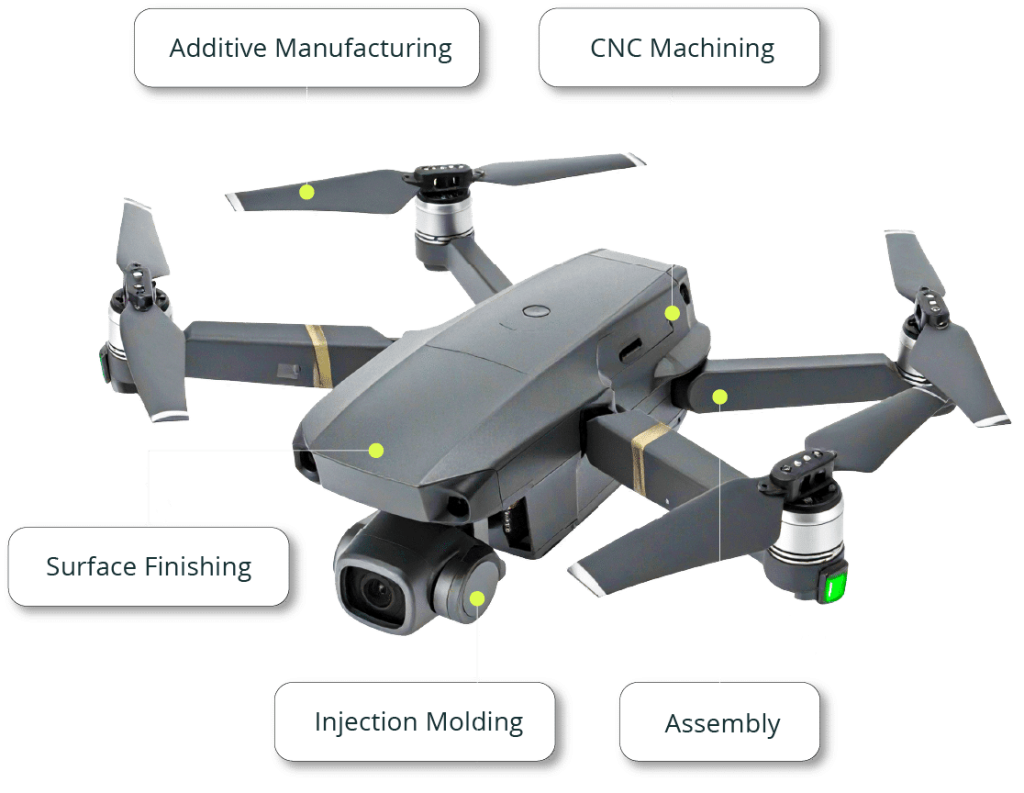

Assembly & Finishing

Trusted by Industry Leaders

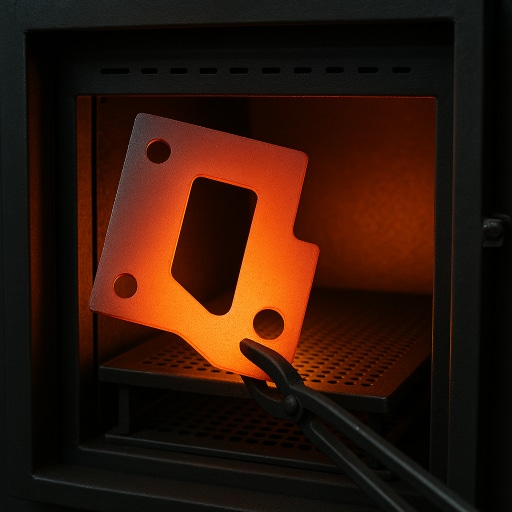

Finishing Options Add Value to Your Parts

We do most operations in-house, saving you time and money

Levels of Finishing

Select the most cost-effective options for your project

| FINISHING GRADE LEVELS | GRADE LEVEL DESCRIPTION | ADVANTAGES & CONSIDERATIONS | |

|---|---|---|---|

| AA (ULTRA HIGH) | High-Resolution Photo-Ready Parts |

|

|

| A (HIGH) | Trade Show or Presentation Parts |

|

|

| B (MID) | Concept Models, Aesthetic Experimentation or Part Comparisons |

|

|

| C (LOWEST) | Concept Validation & Non-Aesthetic Parts |

|

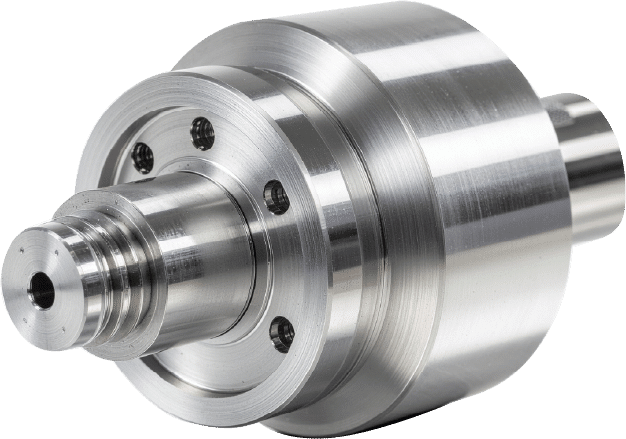

Assembly & Finishing Projects From Fathom

See how Fathom adds value to our customers’ parts using post-processing.

Why Our Customers Trust Fathom

Human-First Engineering

Decades of Expertise

Integrated Manufacturing & Finishing

Full Product Life-Cycle Support

Fathom is Your Product Lifecycle Partner

From early concepts and prototypes to bridge and low-volume production, we’ve got you covered.

Early Concept

We’ll perform a Design for Manufacturability (DFM) analysis to help you optimize your part design for production. Our expert engineers will also identify opportunities for cost reduction in part design, tooling and the proposed production process. Our ultimate goal? To eliminate potential production problems early in your design process.

Rapid Prototyping

Quickly iterate and finalize part designs using our on-demand manufacturing services. Rapid prototyping services employ digital manufacturing methods. They enable designs to move directly from a CAD drawing to a finished plastic or metal part in a matter of hours or days – without the need for tooling. Rapid prototyping can help you bring products to market faster.

Bridge Production

Bridge production can help you solve a number of common problems, including side-stepping tooling delays, meeting regulatory requirements and conducting market research if you’re unsure of demand for your new product. Producing a small quantity of parts enables you to preview a new product to a select audience and make tweaks before you ramp up to full production.

Small-Medium Volume Production

Many third-party manufacturers prefer to avoid low-volume production in favor of long production runs of relatively simple geometries. We specialize in low-volume/high-mix projects. We’re very good at it! Bridge production also makes sense when you’re moving tooling from overseas to domestic production, so you can keep your production line running smoothly.

Kick Off Your Project Today

Expect More From Contract Manufacturing

It’s time to level up your expectations. Contract manufacturing should be much more than an automated quote and superficial DFM feedback. Experience the Fathom white-glove difference – an engineering and expertise-driven process that will guide you from concept to production with clarity, confidence, and zero guesswork.