Are you challenged by staffing and factory space shortages? Is limited floor space constraining your ability to scale up production?

You don’t have to go it alone. Outsourcing functions like final assembly and kitting can help you reduce costs, focus on core competencies and gain flexibility. It can also help you streamline production and use your precious resources more effectively.

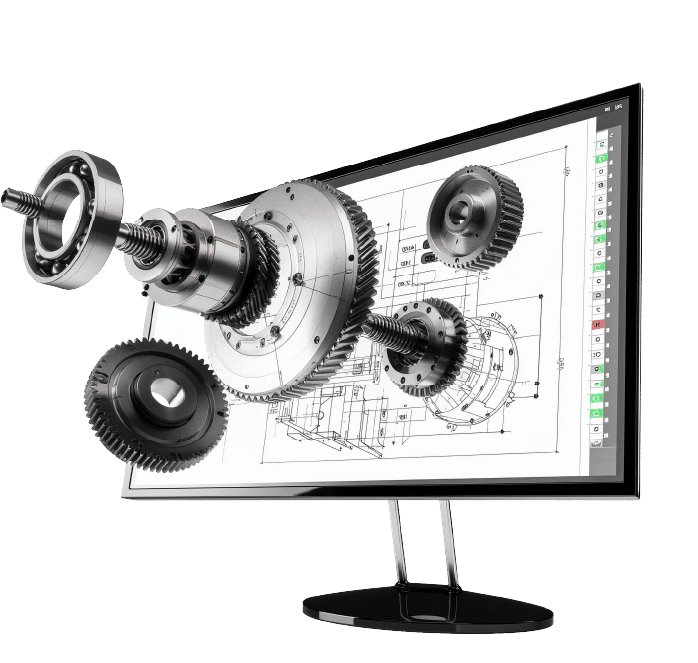

Fathom offers turnkey assembly services to streamline your production process and ensure quality, repeatable builds. Our experienced teams handle everything from sub-assembly to final product integration, helping you reduce vendor coordination, lead time and cost.

In addition, you can use contract assembly to scale production up or down as needed, without the overhead of expanding your own facilities and staff. Finally, a supplier like Fathom can help you meet specific industry requirements, such as the strict regulatory compliance needed for medical device and automotive industries.

We can handle:

- Mechanical assembly

- Simple electromechanical assembly

- Sub-assembly processes

- Kitting