What is Heat Treatment?

Heat treatment enhances the performance of metal by altering its microstructure. It also reduces internal stress, increases wear resistance and enhances ductility, toughness and corrosion resistance. It makes parts easier to machine and more reliable under demanding conditions.

Mechanical Property Enhancement: Heat treatment hardens metal, making it stronger and more resistant to deformation. It enables metal to handle stress and bending forces without failing. It can also enhance a metal part’s wear resistance, critical for applications where it’s exposed to repeated abrasion.

Stress & Workability Improvements: Heat treatment relieves internal stresses created during manufacturing, which prevents warping and makes parts less prone to cracking. This is especially important for 3D printed metal parts made using DMLS and for metal castings. Annealing, a specific type of heat treatment, softens metal, making it easier to machine, cut and form.

Fathom’s Heat Treatment Services

Fathom offers heat treatment services that enhance the properties of the metal parts we manufacture. Here are some of the heat treatment processes we offer.

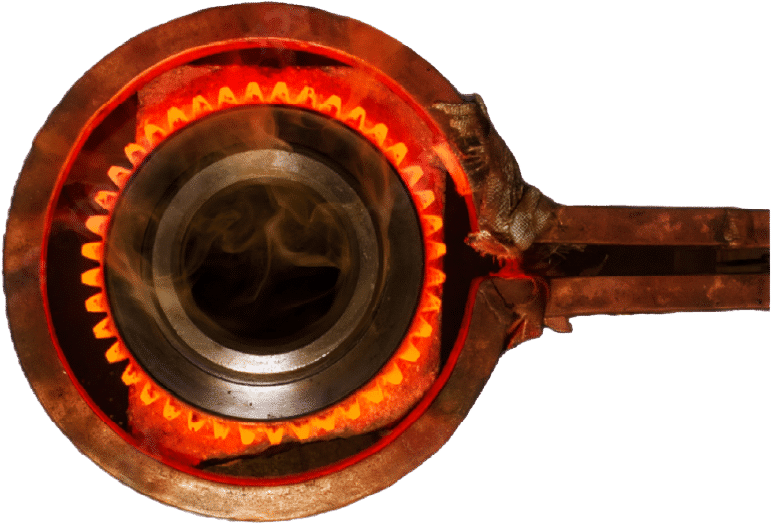

Basic Heat Treating

We heat treat DMLS 3D printed metal parts to relieve stress. We heat treat CNC parts to soften them for machining and then harden them afterward.

Annealing

Annealing is a heat treatment process that involves heating a material to a specific temperature, holding it there, and then slowly cooling it to soften it, improve its ductility and relieve internal stresses.

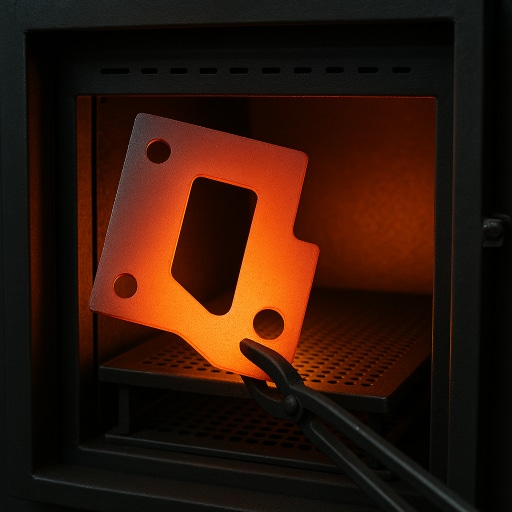

Heat Treating for Machining

Heat treating for machining can be performed before machining to make the material easier to work with by removing internal stresses, or after machining to achieve final properties like hardness and wear resistance needed for demanding applications.

Case Hardening

Case hardening is a heat-treating process that hardens the outer surface of a metal while keeping the interior core soft and tough. The goal is to create a strong, wear-resistant “case” or layer.

Nitriding

Nitriding is a thermochemical heat treatment process that diffuses nitrogen into the surface layer of metal parts, typically steel, to increase surface hardness, wear resistance, fatigue strength and corrosion resistance.

Heat Treatment – Additional Resources

Why Our Customers Trust Fathom

Human-First Engineering

Decades of Expertise

Integrated Manufacturing & Finishing

Full Product Life-Cycle Support

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.