Surface Finishing

Many parts, when they’re first manufactured, aren’t immediately ready for use. They require additional steps – called surface finishing processes – that enhance their performance or aesthetics.

During our manufacturability assessment of your part design, we ask detailed questions about its application. How will it be used? In what type of environment? What forces or conditions will it be exposed to there? Your answers will help us recommend the best and most cost-effective surface treatment that will enhance its value and performance.

Whether your project is additive or traditional manufacturing, we offer the ancillary processes that can help you create an optimal finished product.

Surface Treatment Capabilities

Fathom offers a comprehensive portfolio of surface treatments to enhance the aesthetics and performance of your parts. Surface finishing options vary based on the process used to build the parts.

Here are some examples of the options we offer to our customers:

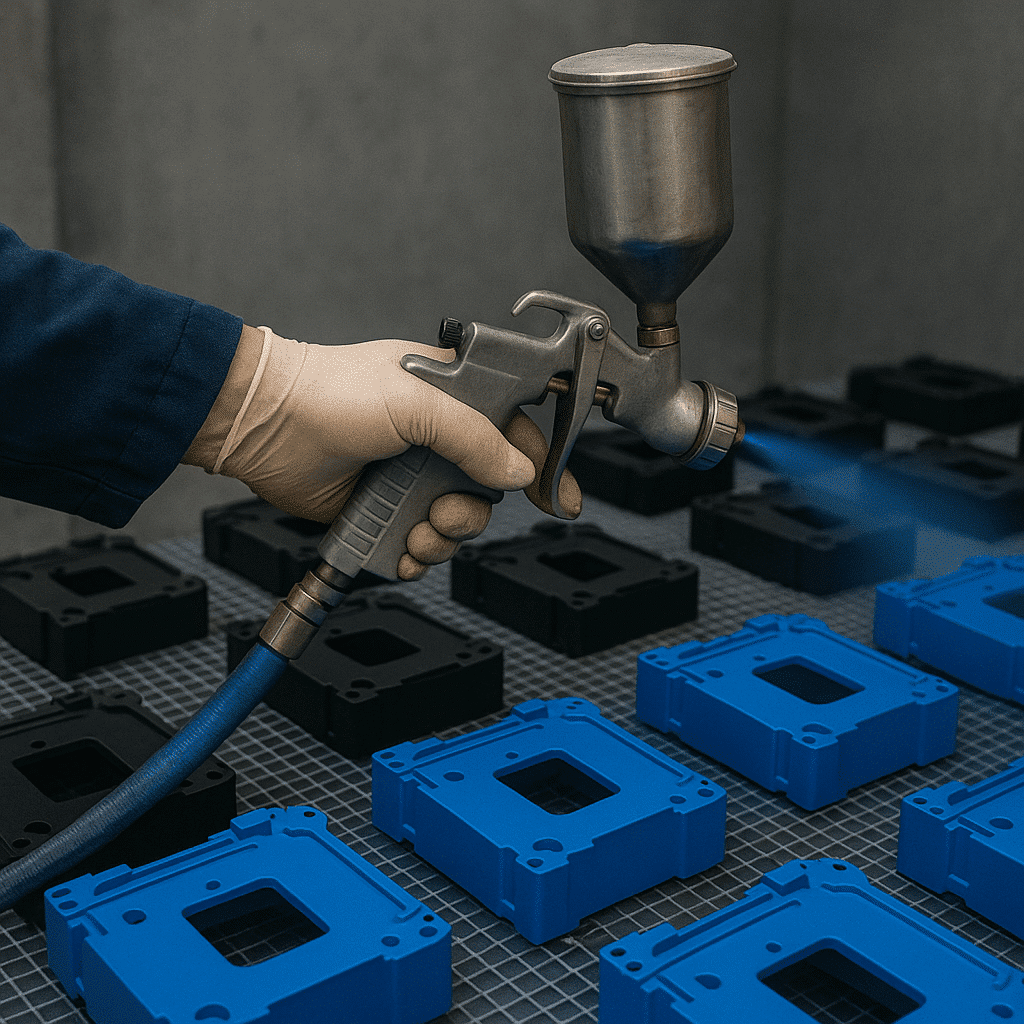

Media Blasting

This process shoots beads or other media at the part to smooth its surface. It’s often used with 3D printed and cast parts.

Vapor Smoothing

This process uses a chemical vapor solvent to melt the outermost layer of 3D printed parts, creating a smooth, sealed surface.

Electroplating

This process deposits a smooth, reflective film on a part to enhance its performance. An example: a plated surface on a hydraulic cylinder.

Laser Engraving

Laser engraving is used on industrial parts to create permanent, high-contrast markings for traceability, quality control, and compliance.

Anodizing

Anodizing enhances corrosion and wear resistance, provides a decorative finish and creates a protective oxide layer on the metal surface.

Passivation

Passivation enhances corrosion resistance of stainless steel by chemically removing surface contaminants and restoring the protective chromium oxide layer.

Industries we serve

Expert engineering, advanced manufacturing and industry expertise is where the magic happens. This combination is what enables us to efficiently move your ideas from concept to production.

Additional Resources Related to Surface Finishing

Why Our Customers Trust Fathom

Human-First Engineering

Decades of Expertise

Integrated Manufacturing & Finishing

Full Product Life-Cycle Support

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.