4-Axis Machining

-

Workpiece Can Rotate to Create More Complex Shapes

-

Tighter Tolerances Than 3-Axis Milling

-

Reduced Production Time

Trusted by Industry Leaders

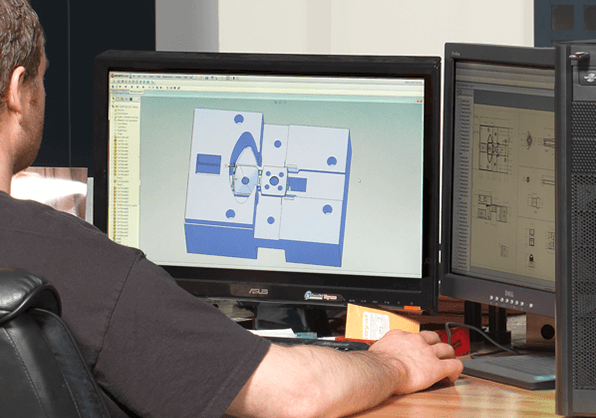

How 4-Axis CNC Machining Works

Is 4-Axis Machining Right For Your Project?

Advantages

-

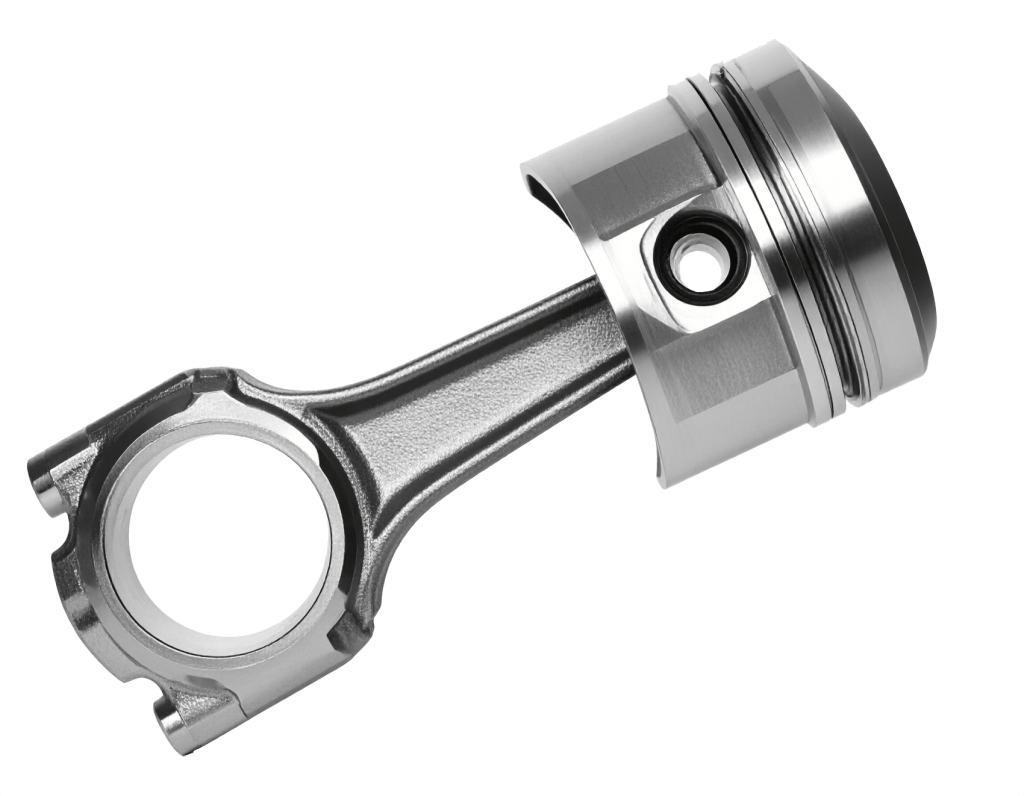

Can Produce More Complex Parts

4-axis machines are ideal for creating intricate designs and curved features that are difficult or impossible with 3-axis machines.

-

Fewer Setups

The addition of the fourth axis allows for multi-sided machining without having to manually reposition the workpiece, which saves time and reduces labor costs. This also contributes to faster production times.

-

Increased Accuracy

Holding the part in a single setup improves accuracy and enables tighter tolerances across multiple sides of the workpiece.

-

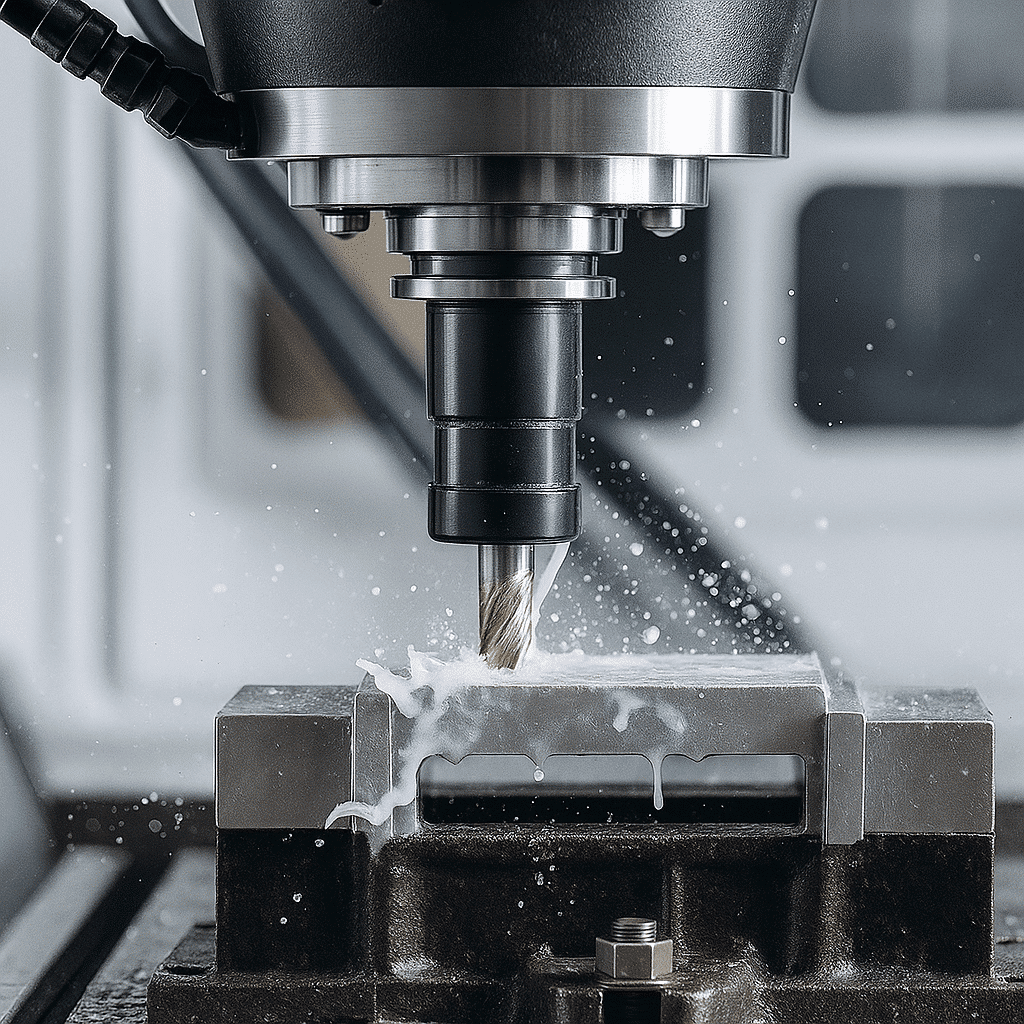

Better Surface Finishes

A single setup can lead to better surface finishes because the cutting tool can maintain a more optimal proximity to the workpiece.

Disadvantages

-

More Complex Programming

Programming a 4-axis machine requires more advanced knowledge to program the additional rotational axis and operate the machine.

-

Potential for Reduced Speed

For certain parts, the rotational movement can sometimes reduce machining speed compared to the simpler, linear movements of a 3-axis machine.

-

Geometry Limitations

Certain complex part geometries require simultaneous movement in more than four axes, which is beyond the capability of 4-axis machines.

Find the Ideal Machinable Material for Your Part

Compare metals and plastics for CNC machining with full property details, tolerances, and suitability notes. Engineered to help you make informed decisions for precision, durability, and performance.