5-Axis Machining

-

Build Complex Parts With Irregular Shapes

-

Improved Precision Because Parts Don’t Need to be Repositioned

-

Improved Surface Finish

Trusted by Industry Leaders

How 5-Axis CNC Machining Works

Is 5-Axis Machining Right For Your Project?

Advantages

-

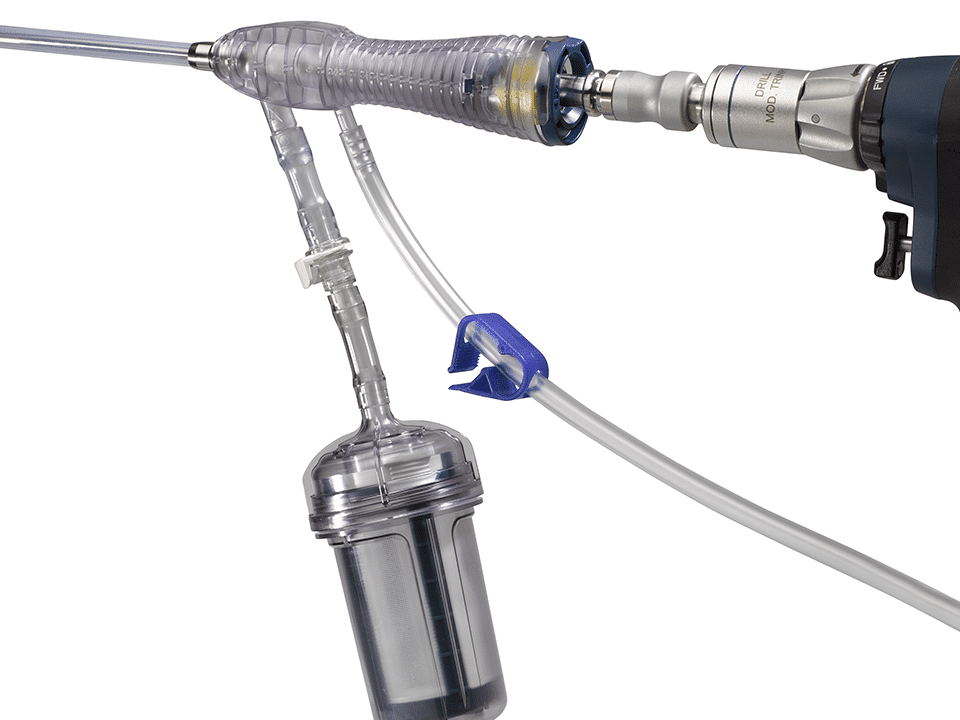

Complex Shapes

5-axis machining can produce intricate designs with curves and angles that are difficult or impossible on 3-axis machines.

-

Increased Accuracy

It can machine multiple sides of a part in a single setup, eliminating the need to reposition the workpiece. This reduces errors and leads to higher precision and tighter tolerances.

-

Reduced Setup Time

By machining multiple faces in a single setup, 5-axis machines significantly cut down on the time and cost associated with multiple setups and fixtures.

-

Improved Production

The ability to machine more complex parts and use shorter tools with higher feed rates leads to faster production times.

-

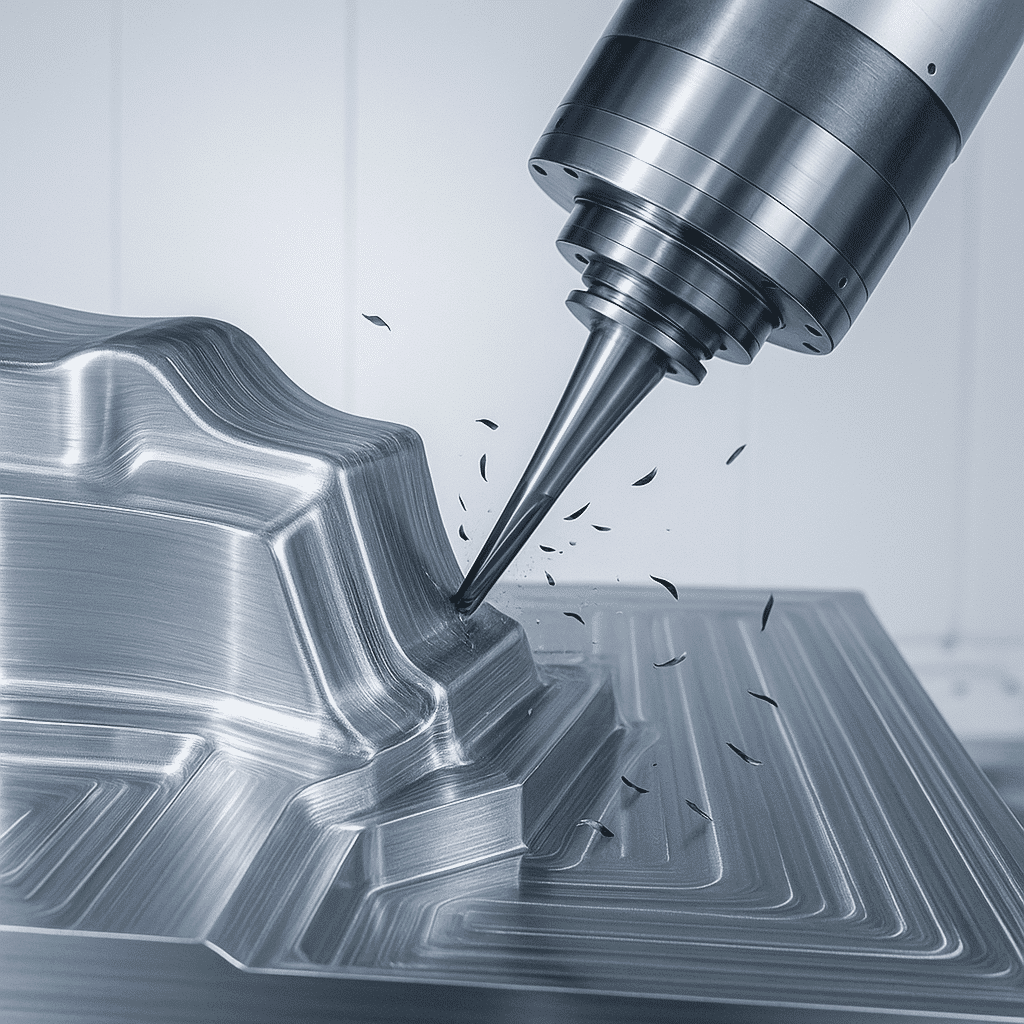

Better Surface Finish

The cutting tool can maintain a more optimal angle with the workpiece, resulting in a smoother, cleaner cut with fewer tool marks.

Disadvantages

-

Operator Skill Level

Operating these machines requires a higher level of skill, including advanced 3D visualization and a thorough understanding of multi-axis motion to avoid collisions and ensure accuracy.

-

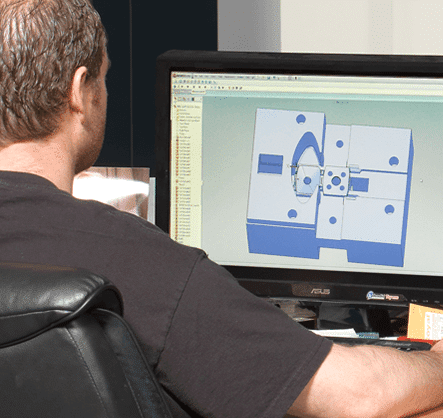

Complex Programming

Creating accurate and efficient tool paths is more complex and requires sophisticated CAM software and a deep understanding of 5-axis principles.

-

Setup Time

Setup and programming can take more time compared to simpler 3-axis machines.

-

Accuracy

Maintaining high position accuracy can be more challenging due to factors like heat generation, mechanical transmission errors, and angular errors in the rotational movements.

Find the Ideal Machinable Material for Your Part

Compare metals and plastics for CNC machining with full property details, tolerances, and suitability notes. Engineered to help you make informed decisions for precision, durability, and performance.