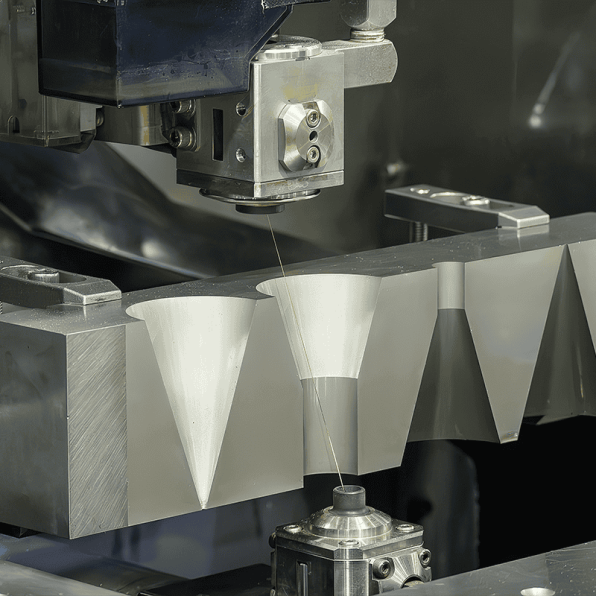

Sinker EDM

-

Make Complex & Irregular Cavities in Metal

-

Cut Shapes That Are Impossible to Machine

-

Ideal For Short Run/High-Mix Projects

Trusted by Industry Leaders

How Sinker EDM Works

What Are the Pros & Cons of Sinker EDM?

Advantages

-

High Precision & Accuracy

Sinker EDM is capable of burning very small and precise holes, often down to a few microns in diameter.

-

Material Versatility

It efficiently burns through extremely hard materials like hardened steel, tungsten carbide and superalloys, which are difficult for conventional machining methods.

-

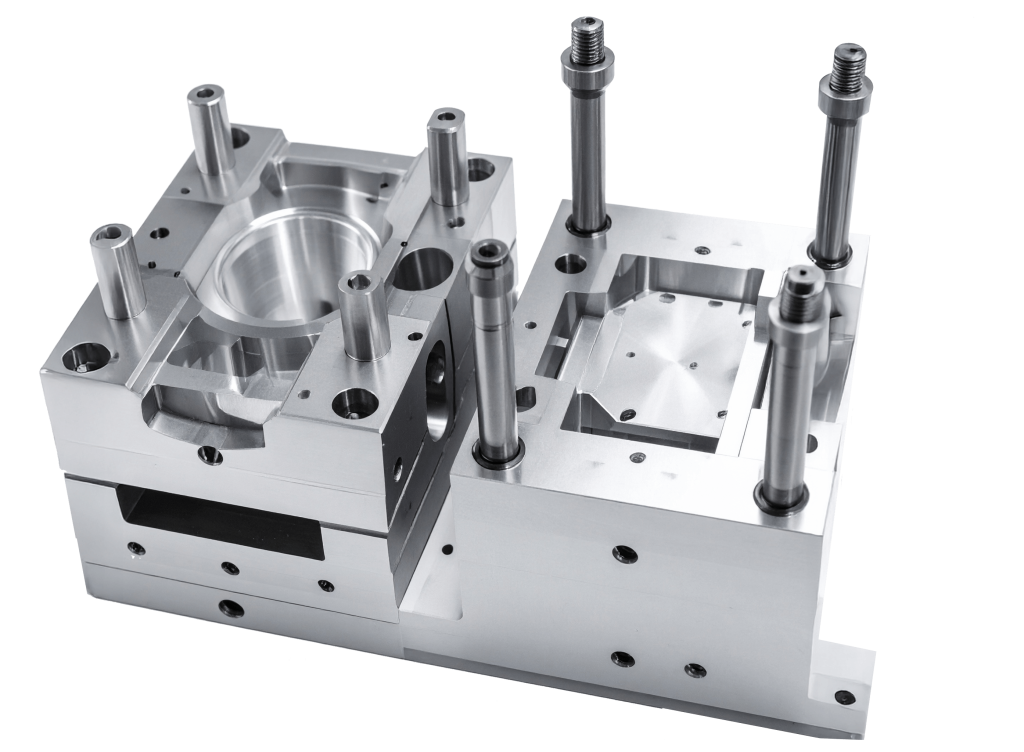

Complex Geometries

Sinker EDM can produce cavities in curved or angled surfaces and can burn deep holes with high aspect ratios that are challenging for traditional machining methods.

-

Non-Contact Process

The sinker EDM process creates burr-free holes and leaves no physical stress on the workpiece. Snker EDM is not limited by material hardness or brittleness. It’s ideal for high-mix, low-volume production projects. Electrodes are easy to manufacture, because they don’t need to be harder than the material they are going to cut.

Disadvantages

-

Limited to Conductive Materials

The sinker EDM process can only machine electrically conductive materials like metals and certain alloys, not plastics or composites.

-

Slow Process

Sinker EDM burning can take several minutes per hole, making it unsuitable for high-volume production

-

Electrode Wear

The electrode wears down during the process, which can be significant and may require replacement or maintenance.

-

High Cost

Both the initial setup and operating costs can be higher than conventional machining due to specialized equipment, energy consumption and labor time.

Kick Off Your Project Today

Expect More From Contract Manufacturing

It’s time to level up your expectations. Contract manufacturing should be much more than an automated quote and superficial DFM feedback. Experience the Fathom white-glove difference – an engineering and expertise-driven process that will guide you from concept to production with clarity, confidence, and zero guesswork.