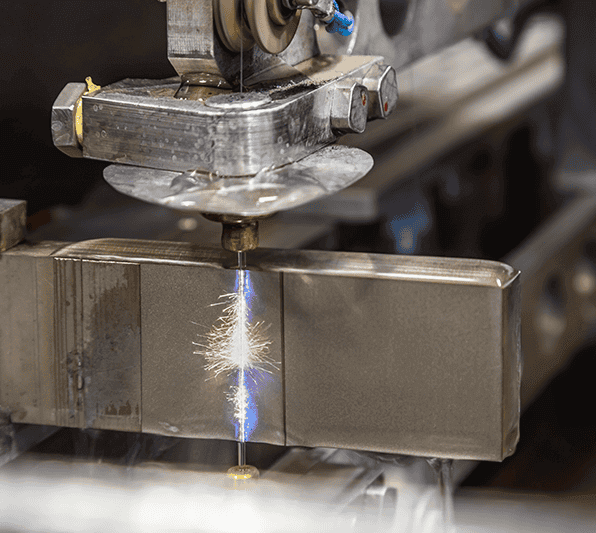

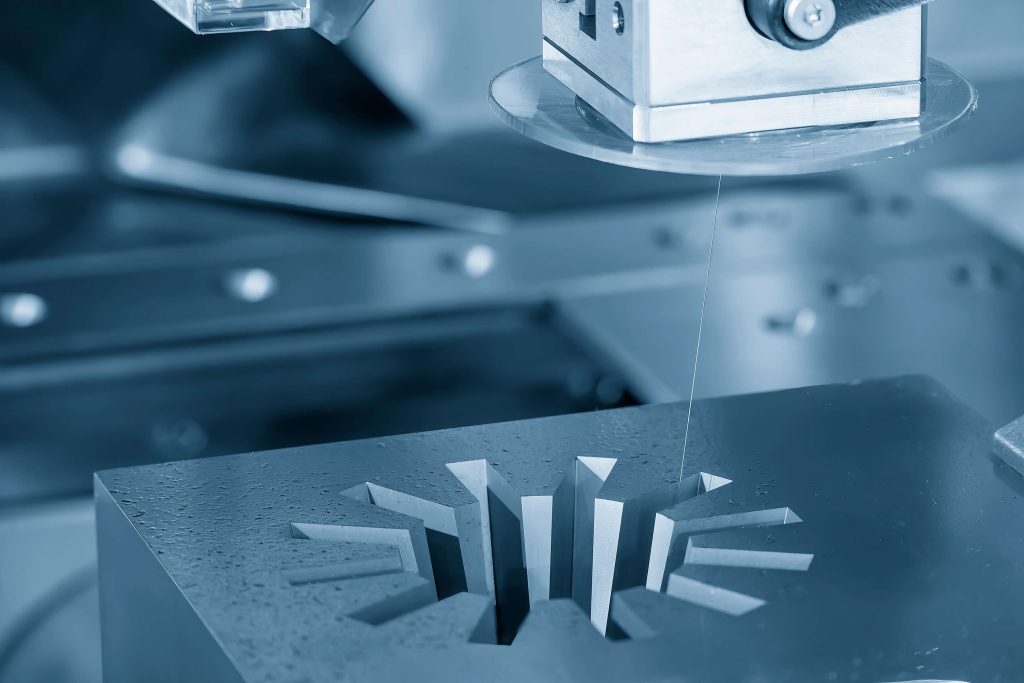

Wire EDM

-

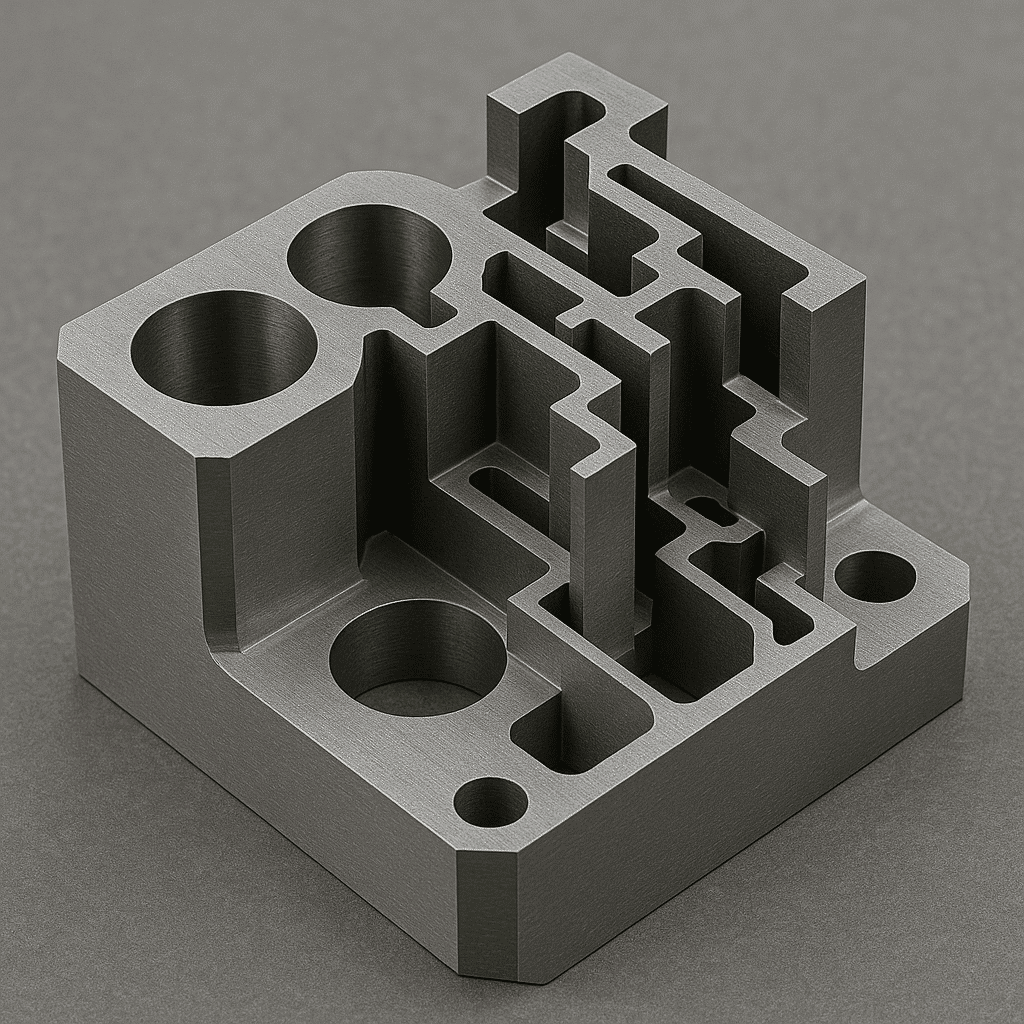

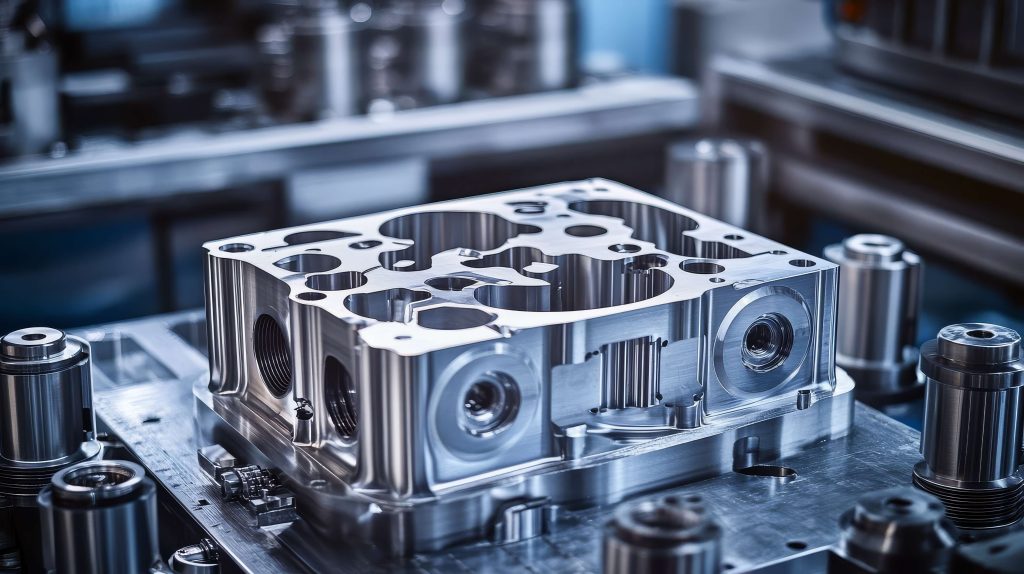

Build Complex Parts with Tight Tolerances

-

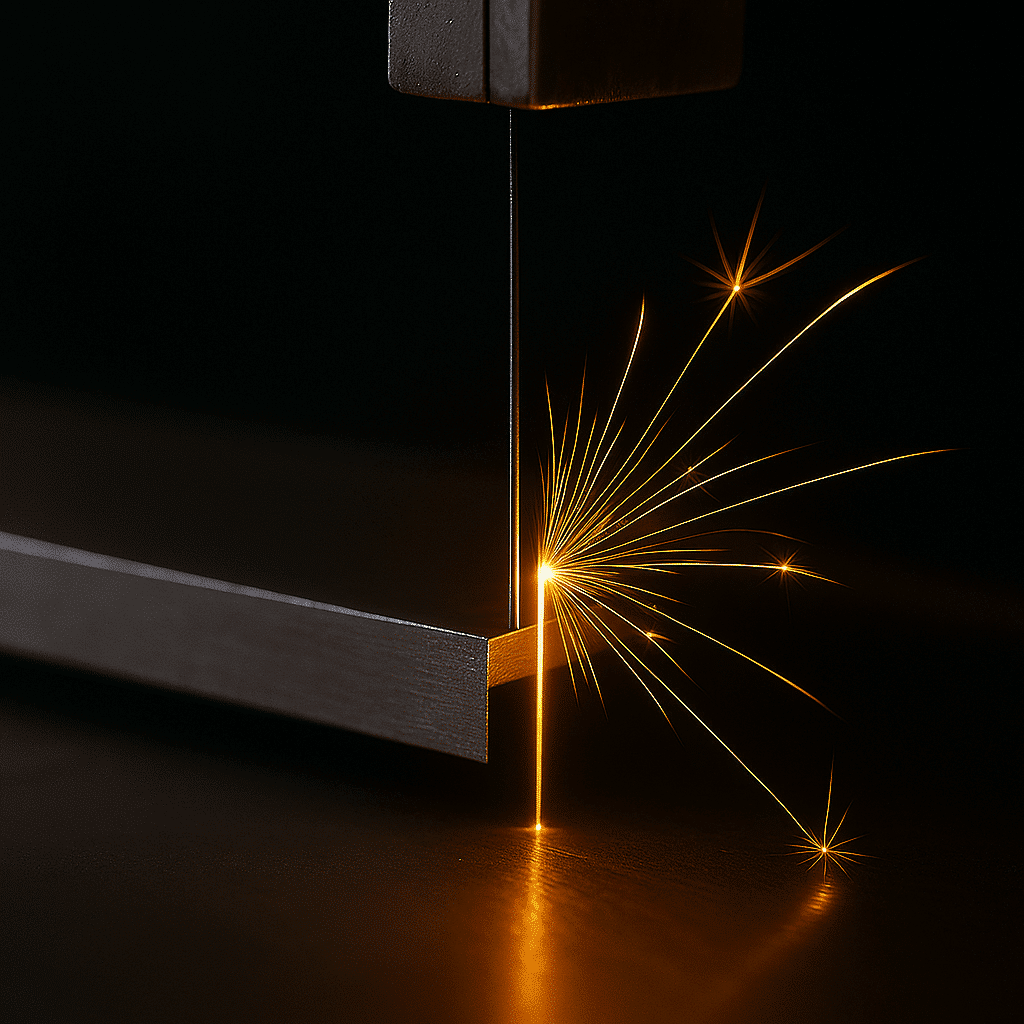

Precision Cutting of Tough Materials

-

Cost-Effective Manufacturing Option

Trusted by Industry Leaders

How Wire EDM Cutting Works

What Are the Pros & Cons of Wire EDM Cutting?

Advantages

-

Precision & Accuracy

Wire EDM machining makes precise and accurate cuts, often within ±0.0002 inches, and cut intricate details with high accuracy.

-

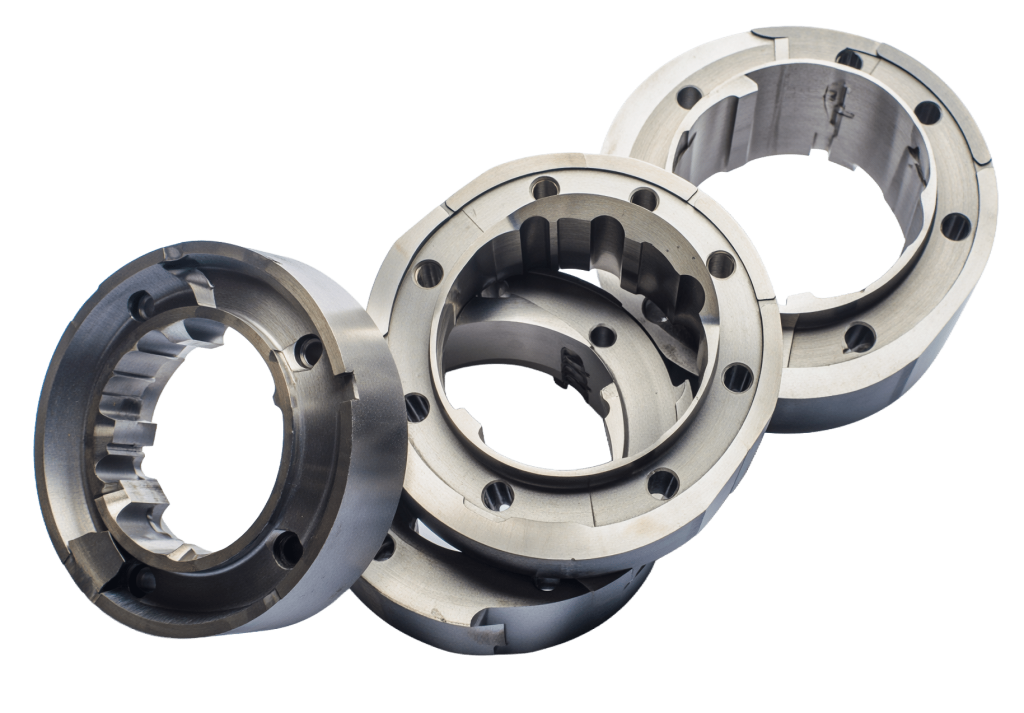

Tight Corners

Wire EDM cutting can create extremely tight corner radii, which is difficult with conventional machining methods. This capability is ideal for fabricating injection mold tools.

-

Ideal for Cutting Tough Materials

Wire EDM can cut extremely hard, strong, and difficult-to-machine conductive materials that are challenging for traditional machining, such as Inconel, titanium and superalloys.

-

Efficient for Cutting Brittle Metals

The lack of mechanical contact between the wire and the workpiece means delicate or weak parts can be machined without distortion.

-

Cost Effective

Wire EDM cutting is surprisingly efficient: Metal plates can be stacked to cut multiple workpieces in a single pass.

Disadvantages

-

Conductivity Requirement

Wire EDM can only machine electrically conductive materials, such as metals. It cannot cut non-conductive materials like most plastics, ceramics, or composites.

-

Slow Cutting Speed

Wire EDM cutting is significantly slower than conventional machining, water jet cutting, or laser cutting, making it less efficient for simple or high-volume jobs.

-

Heat-Affected Edges

A thin layer of oxide or recast material can form along the cut edge, which may need to be removed with a secondary process like electropolishing

-

Skilled Operator Required

Wire EDM requires significant operator expertise to set up and run correctly.

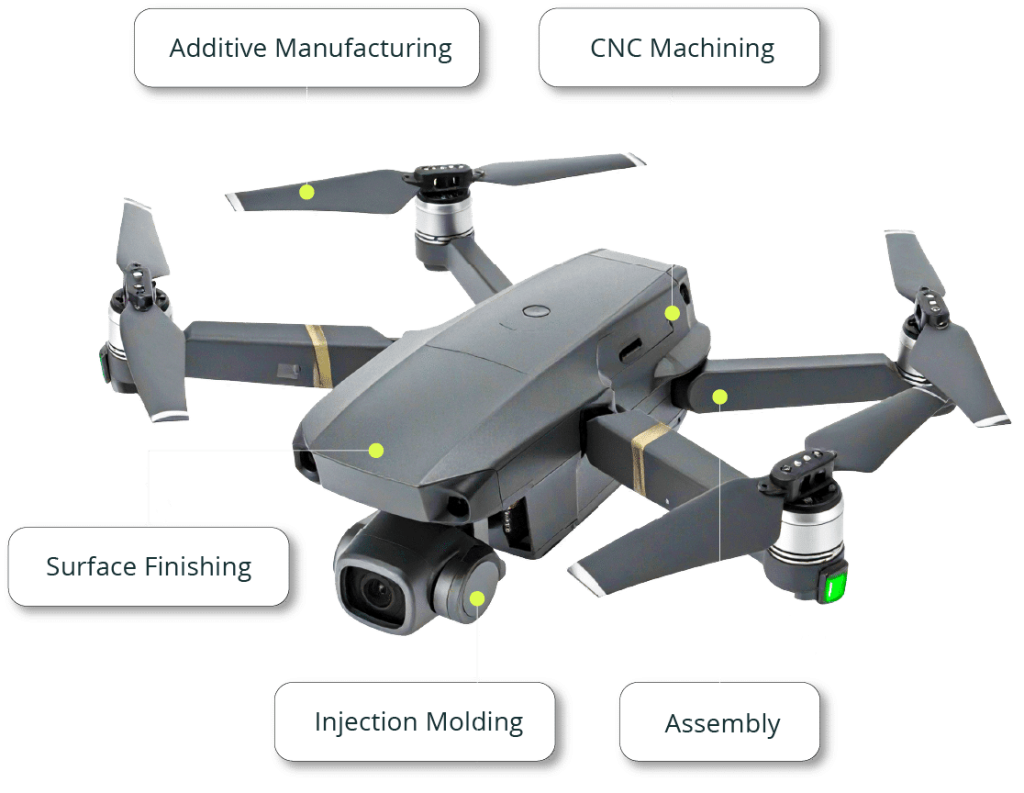

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.

Kick Off Your Project Today

Expect More From Contract Manufacturing

It’s time to level up your expectations. Contract manufacturing should be much more than an automated quote and superficial DFM feedback. Experience the Fathom white-glove difference – an engineering and expertise-driven process that will guide you from concept to production with clarity, confidence, and zero guesswork.