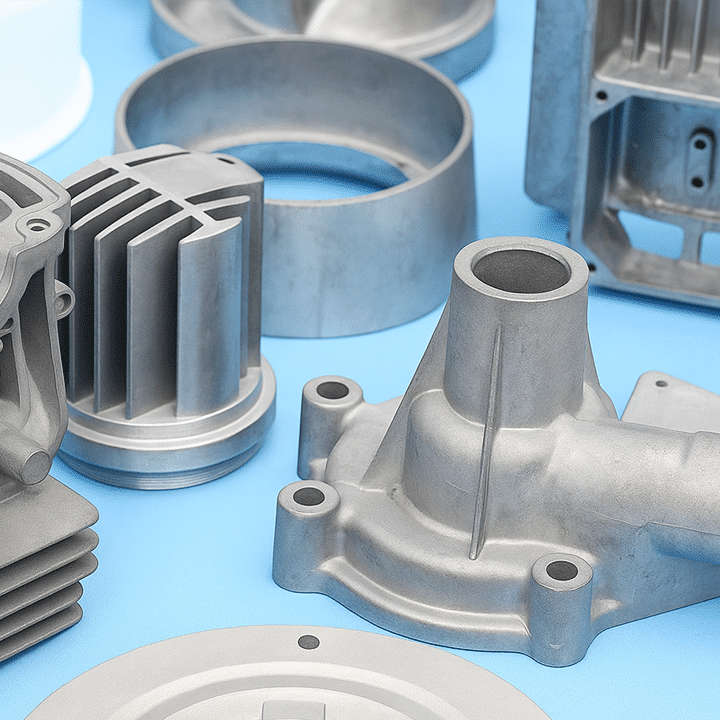

Q.

What materials are used in die casting?

Common materials include aluminum, zinc, and magnesium alloys. Hot chamber die casting is typically used for lower melting point metals like zinc, while cold chamber is used for higher melting point metals like aluminum.