Low-Pressure Die Casting (LPDC)

Get a Quote

Trusted by Industry Leaders

How Does Low-Pressure Die Casting Work?

Is Low-Pressure Die Casting a Fit for Your Needs?

Advantages

-

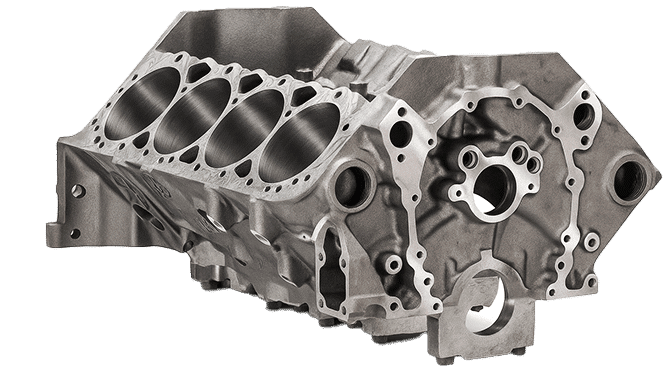

Improved Metal Flow and Porosity

LPDC ensures even metal flow, which reduces turbulence and minimizes trapped air. The result: few porosities and stronger, more reliable castings compared to high-pressure die casting.

-

Better Mechanical Properties

Parts produced under low pressure generally have higher density and fewer internal defects. This improves tensile strength, fatigue resistance and overall durability compared to high-pressure die casting.

-

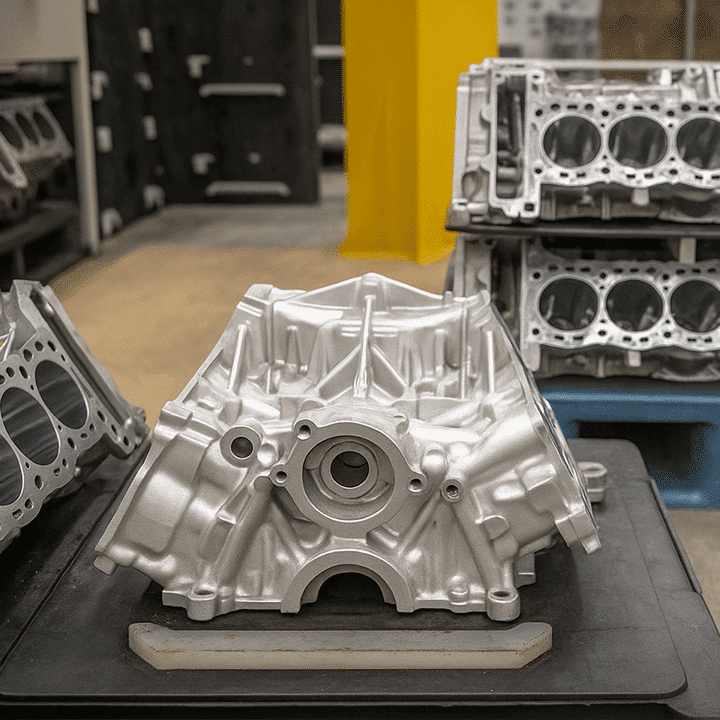

Dimensional Accuracy

The controlled flow enables precise filling of intricate mold features. This reduces the need for extensive machining or post-processing.

-

Reduced Material Waste

Overflow is minimal because the metal is pushed gradually into the mold. This conserves expensive alloys and keeps scrap rates low.

-

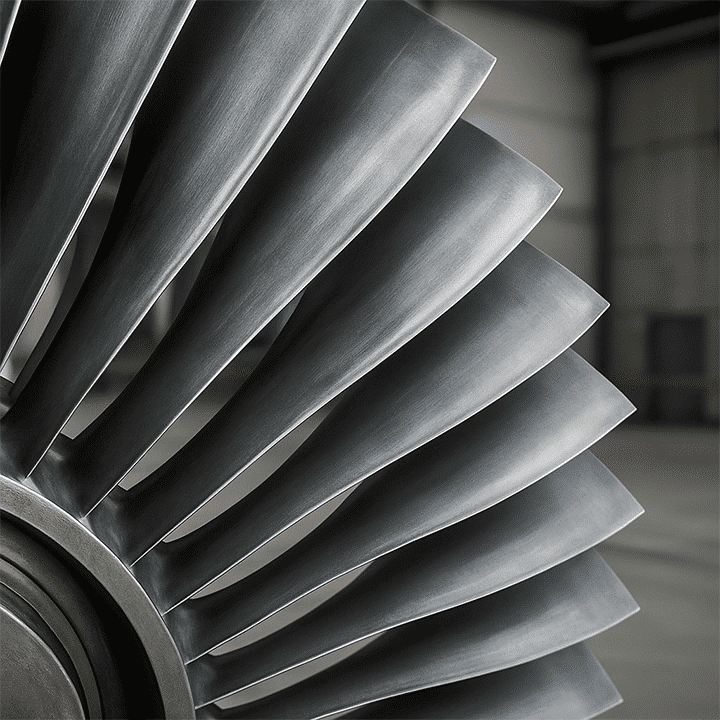

Thin Walls & Complex Shapes

LPDC excels at producing parts with thin sections that are difficult to achieve through gravity casting. Complex geometries can be formed without compromising structural integrity.

Disadvantages

-

High Initial Costs

LPDC requires specialized furnaces, pumps and molds. The initial investment is significantly higher compared to gravity casting or other simpler methods.

-

Slower Production Rate

Filling the mold under low pressure is slower than high-pressure die casting. This can limit production speed, especially for large part orders.

-

Complex Process Control

Operators must precisely control temperature, pressure and timing. Even small deviations can lead to defects such as cold shuts or incomplete filling.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.