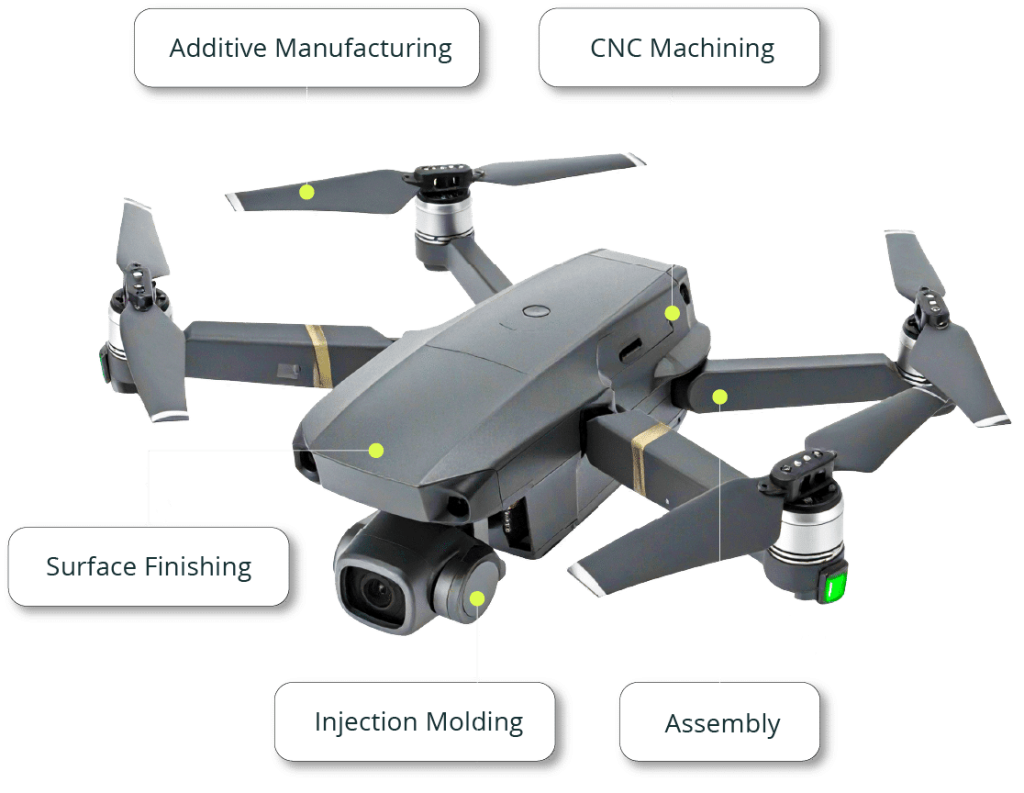

Q.

What materials can be used?

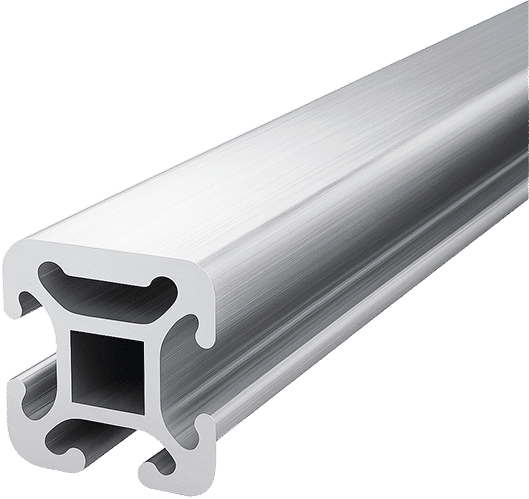

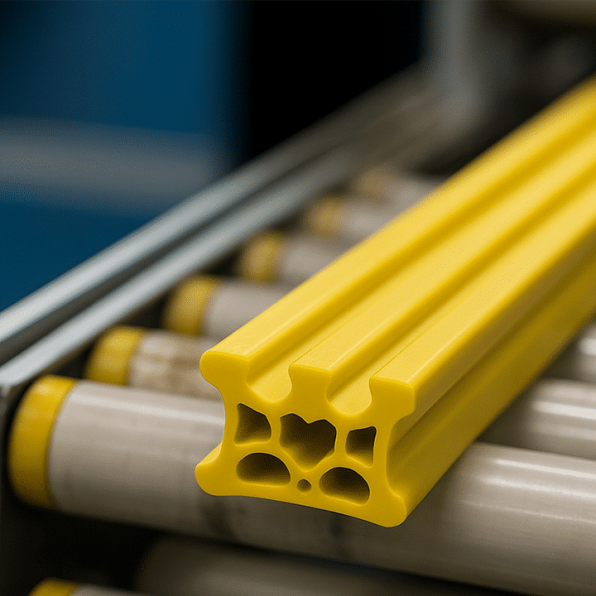

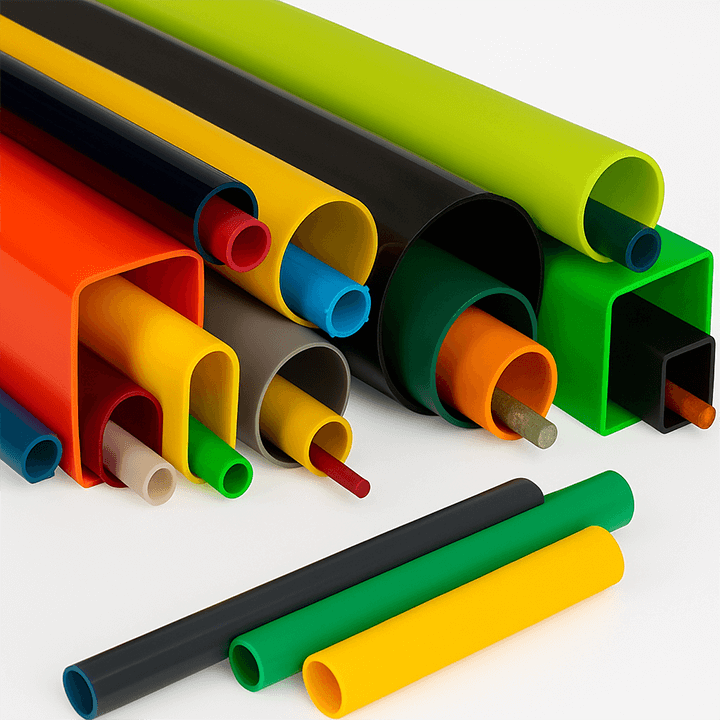

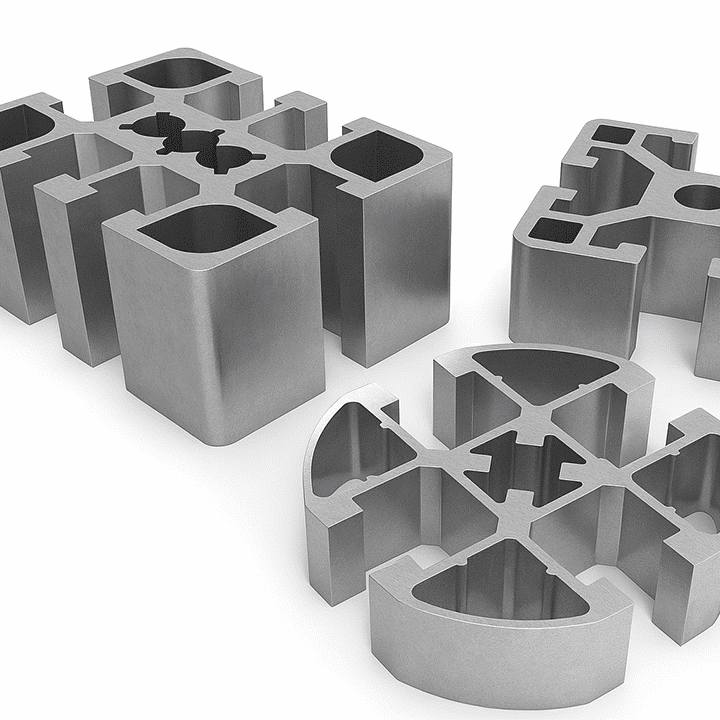

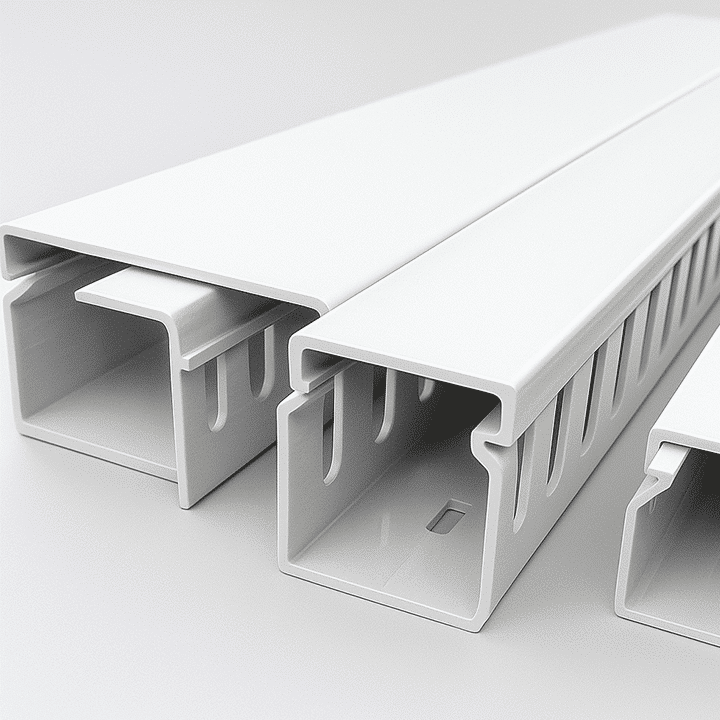

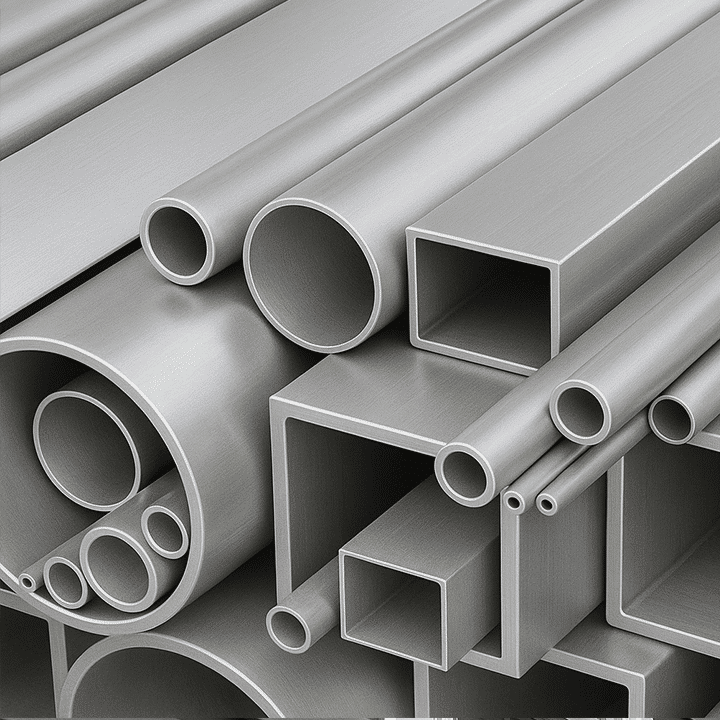

Common materials include PVC, ABS, and various polyethylenes for plastics, and aluminum for metals. For plastic, the best material depends on the desired properties like temperature resistance, chemical exposure and strength, which can be enhanced with additives like fiberglass or flame retardants.