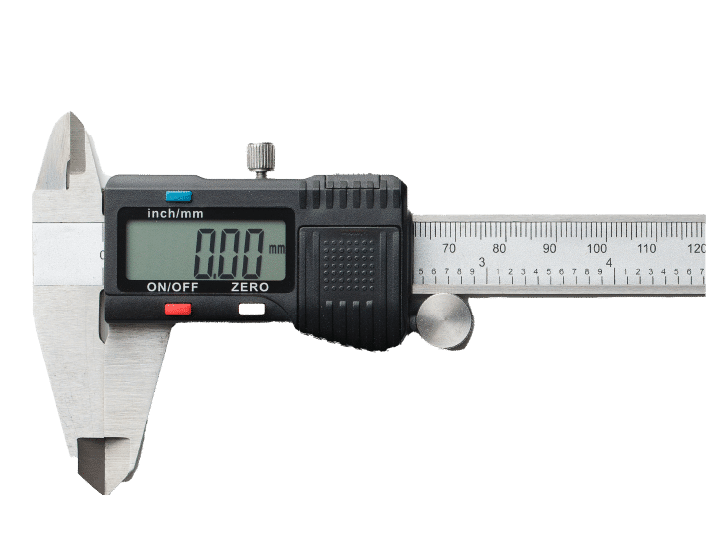

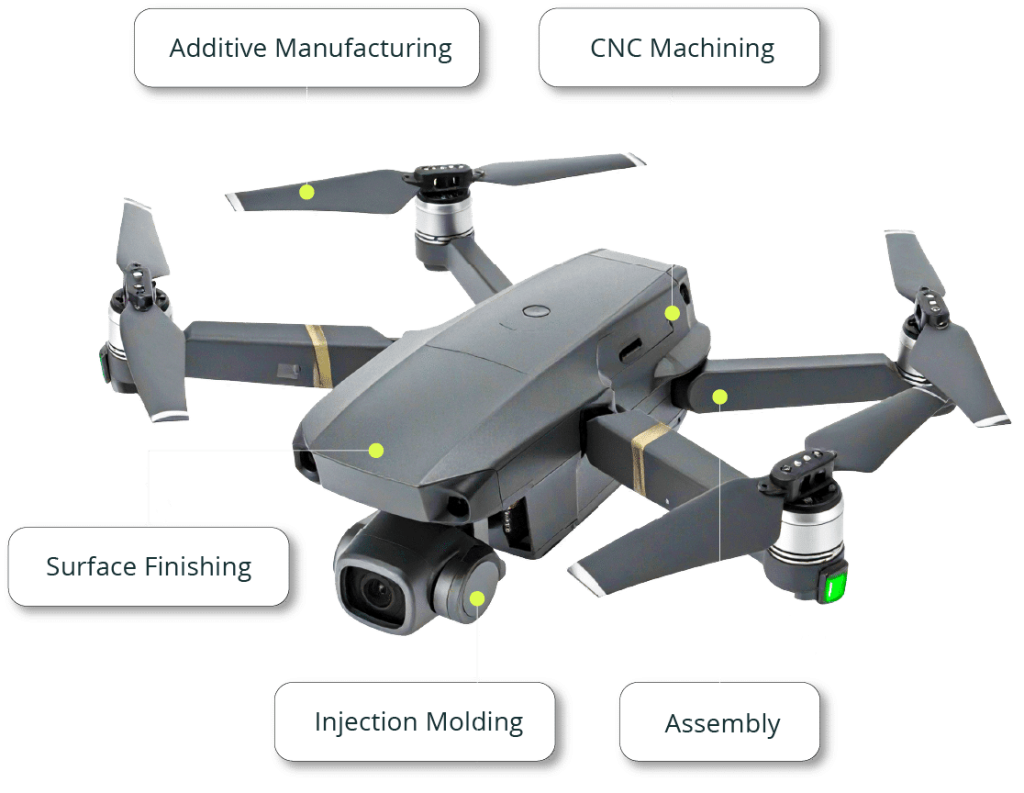

Inspection services are critical to verify quality, catch defects early, ensure compliance and prevent costly issues like recalls. Inspection processes are used to systematically check components against specifications throughout production to guarantee the parts delivered to our customers are reliable, safe and meet our customers’ expectations.

Key Roles of Inspection Services

Quality Assurance: Inspections confirm that every part meets required dimensions, tolerances and material properties.

Defect Detection: Inspections identify flaws, damage, contamination or incorrect assembly early in the process to prevent them from escalating.

Cost Reduction: Catching problems early avoids expensive rework, scrap and potential product recalls later.

Process Improvement: Inspections provide vital data that help us optimize our manufacturing processes.

Safety & Compliance: Inspections help ensure that products are safe for use and adhere to industry standards and regulations.

Customer Satisfaction: Inspections help to build trust by helping us deliver reliable, high-quality parts that meet our customers’ expectations.