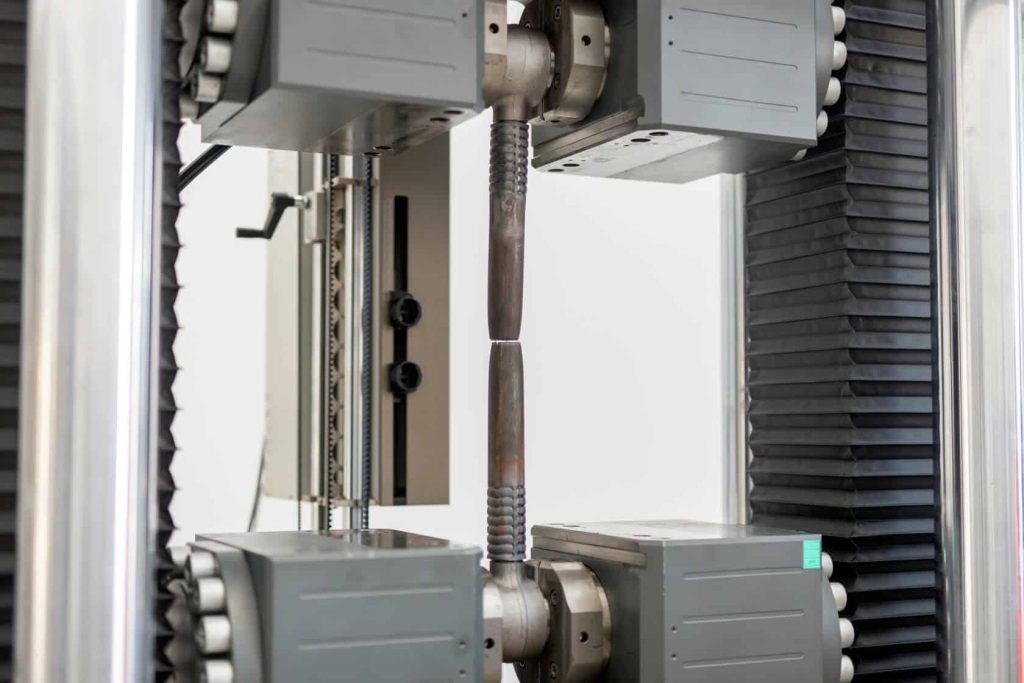

Fathom offers destructive testing services to help verify the strength, durability, and performance of materials and components produced across our manufacturing technologies. By testing to failure, we provide valuable data that informs design improvements, material selection, and process control — ensuring that every part meets or exceeds performance expectations.

Common tests include:

- Tensile testing

- Material and weld integrity testing

- Hardness and impact testing

- Fatigue testing

These tests provide valuable data for product development, material certification, and ensuring parts meet safety and design specifications.