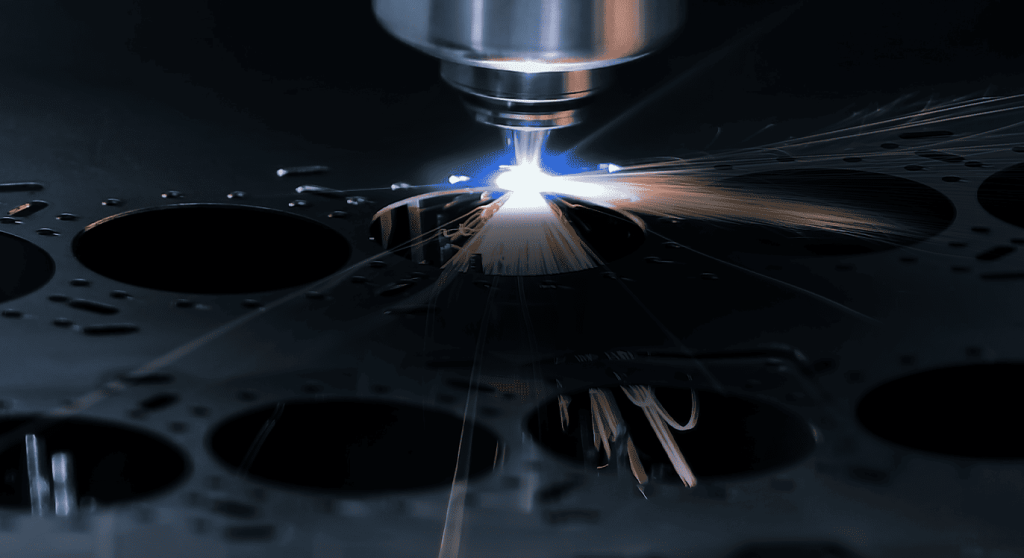

Laser Cutting

-

Precise & High Quality Cut Edges

-

Production-Grade Repeatability

-

Eliminates Need for Additional Finishing

Trusted by Industry Leaders

How Laser Cutting Works

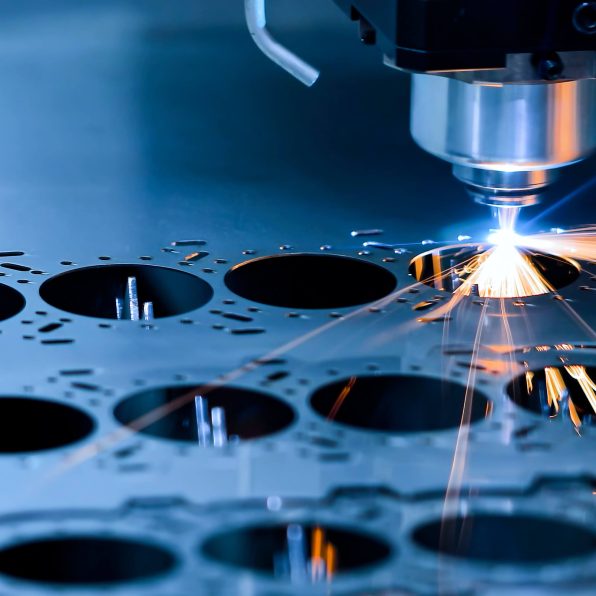

Laser cutting utilizes a CNC-controlled, high-powered laser beam to cut, engrave or etch material. Because the kerf width is barely larger than the laser beam, it can be used to cut very fine geometries and intricate shapes. There are two main types of laser cutters used to cut sheet metal: CO2 and fiber lasers. In addition to cutting, a laser cutter can etch sheet metal to add features such as part numbers or serial numbers.

Laser cutters follow the CAD design to create cuts, holes and engrave the sheet metal. Our fiber laser cutters have a kerf width of .008 inches. That makes them ideal for cutting complex details. Our lasers can cut .010-.50″ thick materials, +/- .005” with the possibility of tighter tolerances based on project specs. We can cut a wide range of materials, including aluminum, carbon steel, stainless steel and copper.

Industrial laser cutting produces high-quality edge finishes that require little or no post-processing. Some cleanup of burn marks may be required. The laser may also cause narrow heat-affected zones along the cuts, which could affect the properties of the metal, including brittleness, oxidation and corrosion. Post processing for laser-cut sheet metal may include deburring, sanding, polishing, welding, painting, and anodizing.

How Does Industrial Laser Cutting Compare to Other Cutting Methods?

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | ||

|---|---|---|---|---|---|---|---|---|

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast | |

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° | |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. | |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon | |

| * CHEMICAL ETCHING | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

Advantages & Disadvantages of Laser Cutting

Advantages

-

Affordability

High speed and high quality make industrial laser cutting very cost-competitive and a real value for our customers. It’s an ideal process for prototype to low-volume production quantities of laser cut parts.

-

Automation

Laser cutters at our Denver facility are equipped with automatic loading and unloading systems, enabling us to process large orders on a lights-out basis. That helps us keep our costs competitive and helps us deliver your finished parts faster.

-

Precision Details

Laser cutting can produce small, precise holes and fine details in sheet metal.

-

Tight Tolerances

CNC controls maintain critical tolerances while accommodating fine features and larger blank sizes.

-

Quick Turn-Around

Laser cutting jobs can be set up and running quickly – perfect for fast turnarounds on small batches of parts. Because laser cutting doesn’t apply any physical forces to the sheet metal, it doesn’t need to be held in place with jigs or work-holding fixtures. That speeds up the setup and production times.

-

Little or No Finishing Required

Industrial laser cutting produces high-quality edge finishes that require little or no post-processing. Some cleanup of burn marks may be required.

-

Maximize Material Use

Multiple parts can be cut from the same sheet. That helps to minimize waste.

Disadvantages

-

Heat-Affected Zones

Because laser cutting generates heat, it can alter the chemical and structural characteristics of the metal near the cutting edge – called “heat-affected zones” (HAZ). Effects may include oxidation, brittleness and corrosion. However, laser cutting generates smaller heat-affected zones than other thermal cutting techniques.

-

Material Limitations

Laser cutting can’t cut through thicker sheet metal. Water jet cutting works better for thick materials.

Applications That Can Benefit From Laser Cutting

Automotive & Aerospace

These industries need precise, high-tolerance parts for a variety of applications. Laser cutting can cut complex shapes in tough metals that are needed for these demanding industries.

Medical Equipment

Laser cutting is used to cut large panels for X-ray and MRI machines. It’s also used to build enclosures for a variety of monitoring equipment. The exceptional efficiency of laser cutting makes it a popular choice for cost-conscious medical device manufacturers.

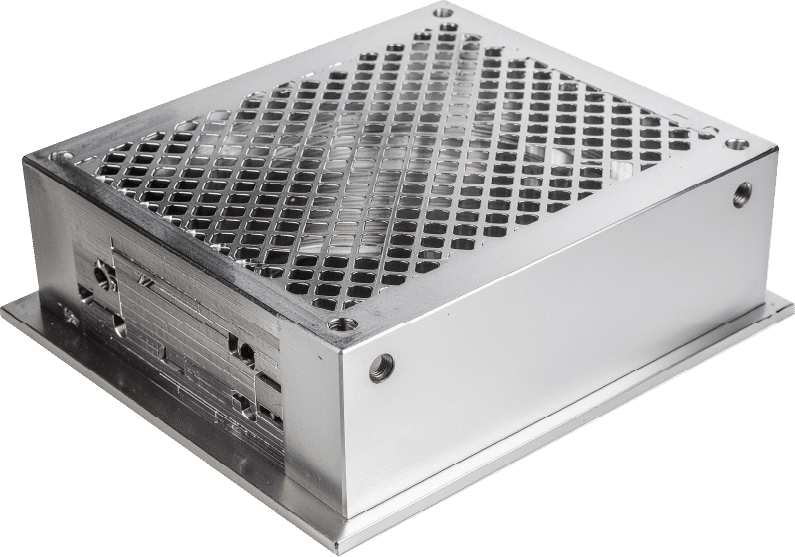

Electronics

Laser cutting of sheet metal is used to create enclosures and precision components for a wide variety of electronic devices. Its quick turnaround makes it especially attractive as a tool for rapid prototyping of new devices.

Off-Highway Equipment

Laser cutting is used to cut durable body panels and other components for construction, mining and agricultural equipment.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.

Laser Cutting – Additional Resources

Why Our Customers Choose Fathom

-

Our expert engineers will help you optimize your part designs for production.

-

Our engineering and production teams bring decades of expertise and problem-solving to every project.

-

We offer manufacturing and full post-processing capabilities under one roof for one point of accountability

-

We’re your partner from design and prototyping to bridge and full production.