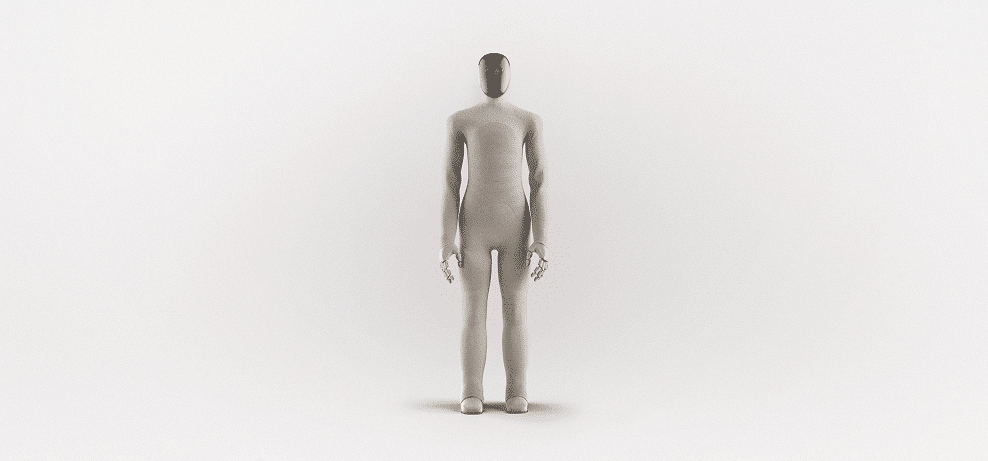

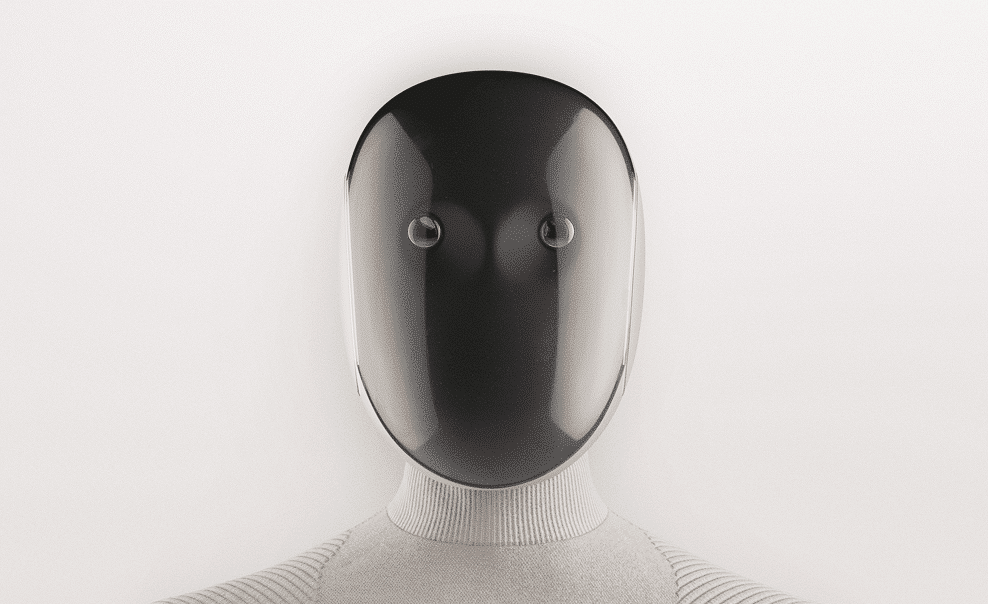

NEO Gamma Robot

-

CLIENT:

1X Technologies

-

INDUSTRY:

Robotics

-

CAPABILITIES USED:

3D Printing

1 Week Saved With 3D Printing

Fast Response to Immediate Need

White Glove Treatment in Action

Fathom Fast-Tracks Critical Robot Components With 3D Printing

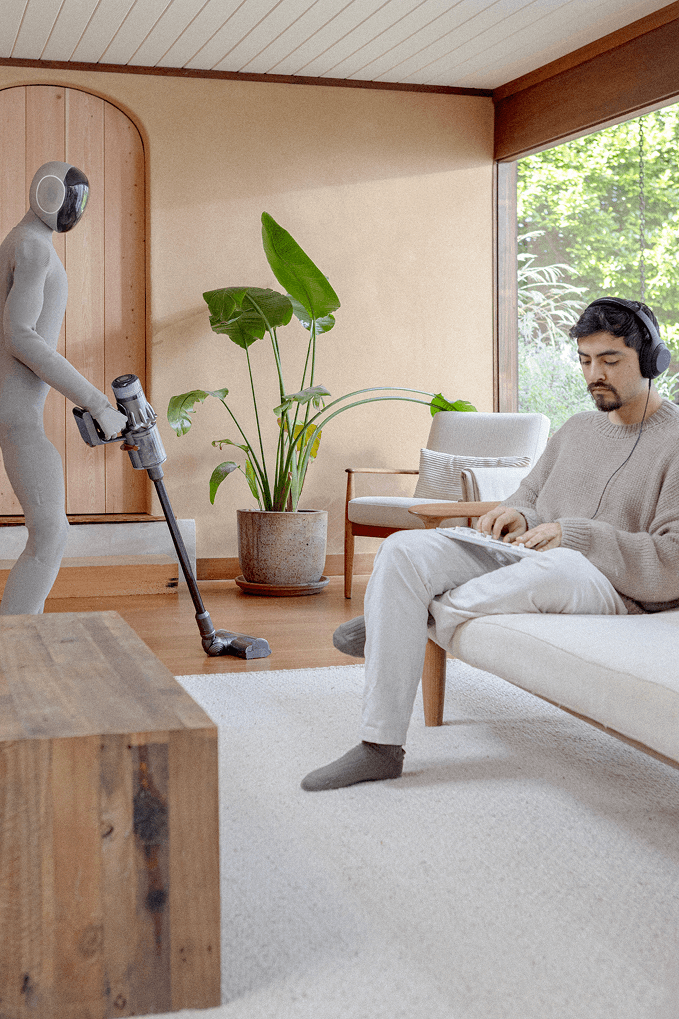

When robotics and AI startup 1X Technologies needed to present its flagship humanoid robot, NEO Gamma, to investors, it needed a number of components to complete its prototype robot. It was seeking a supplier for CNC machined parts, but had run out of time to get them produced. The company turned to Fathom to produce them using 3D printing to beat a last-minute deadline.

The Problem

-

1X Technologies faced critical hurdles in preparing its new NEO Gamma humanoid robot for investor review. The key stumbling block was time – not money or tricky part geometries.

-

Prototype components (torso and hand parts) were urgently needed to complete functional models.

-

Delays in manufacturing these parts risked derailing investor presentations, potentially shaking confidence in 1X Technologies’ viability as a startup.

-

Exceptional part quality was non-negotiable; the humanoid had to impress investors.

The Solution

Fathom initially proposed CNC machining to build the needed parts. But the short timeframe of this project required a pivot to a faster alternative: 3D printing. Fathom was able to adapt the CAD designs to 3D printing without any issues. Although 3D printing is less precise than CNC, the Fathom team was able to achieve exceptional accuracy, eliminating the need for additional finishing.

The Results

-

Switching from CNC machining to 3D printing cut a full week from the project timeline.

-

The 1X team picked up the parts from Fathom and flew them to Sweden, where final assembly took place less than 24 hours after printing.

-

The company was able to showcase NEO Gamma at its investor demo as scheduled in Sweden.

-

The 1X Technologies team gained important insights into part tolerances as a result of this project.

1 Week Saved With 3D Printing

Fast Response to Immediate Need

White Glove Treatment in Action

Real Customers. Real Results.

Our Human-First Approach Comes Through Under Pressure