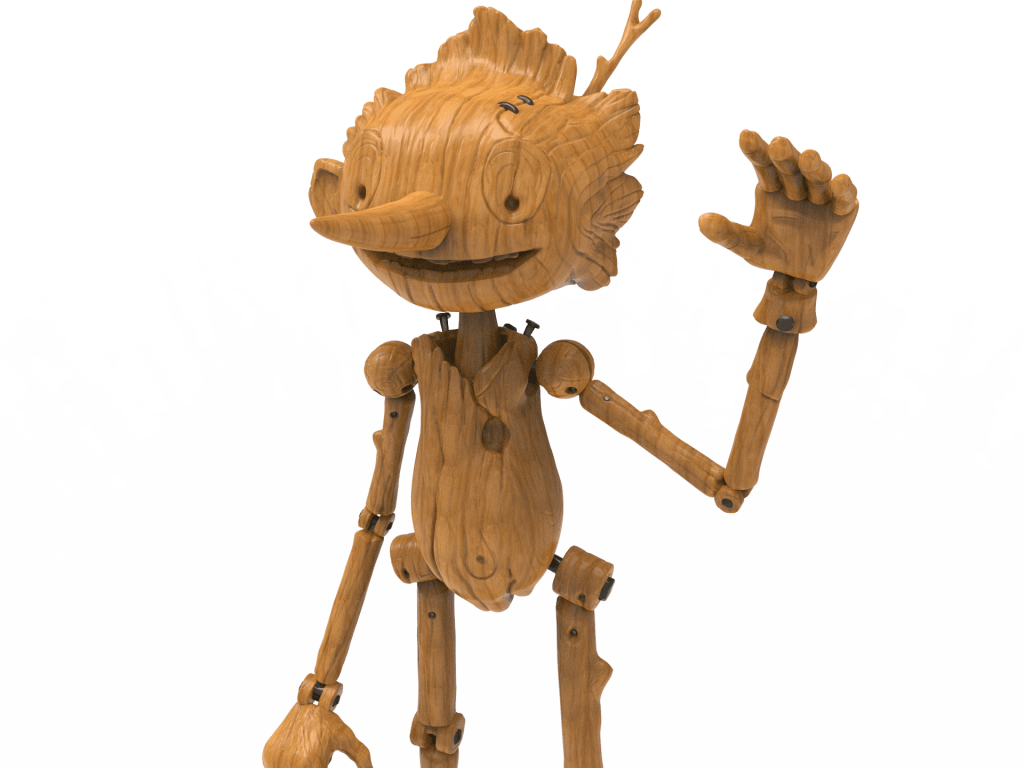

Guillermo del Toro’s Pinocchio

-

Client

Guillermo del Toro

-

Industry

Entertainment

-

Capabilities

PolyJet

Fathom is hiring for multiple positions across our nationwide sites! To see all open positions, click here

From prototyping to production, Fathom delivers precision manufacturing at scale. Explore our comprehensive suite of U.S.-based services—from CNC machining and molding to advanced metrology and outsourced solutions—trusted by leaders in aerospace, medical, robotics, and beyond. Every project is backed by expert support, strict certifications, and scalable technology.

Fathom provides full-spectrum manufacturing solutions tailored to your product journey—from early-stage concept to scalable production. Our services are built to accelerate timelines, reduce costs, and ensure quality across every phase.

Helping you solve your biggest manufacturing challenges – with White Glove Service

Leverage our deep engineering expertise and white-glove support from prototype to production to bring your new products to market faster.

Tariffs. Instability. Margin Pressure. Fathom Edgeworks was built to outsmart the chaos and outprice the competition.

We specialize in high-stakes sectors where precision, speed, and reliability matter most. Explore how Fathom supports innovation across regulated and fast-moving industries.

High-precision where performance and compliance matter most.

Quality controls for regulated environments.

For tight tolerances, reliability, and scale.

The consistency and control for advanced fabrication.

Precision for reliability, repeatability, and production readiness.

Accelerating ICT infrastructure builds with less risk—from prototype through ramp.

All other industries beyond our five primary markets.

Stay ahead with expert content, guides, and case studies that support smarter decisions and better manufacturing outcomes.

Fathom customers love our hands-on approach to engineering and production. Read the stories.

Check out our industry events, facility tours, and expert-led manufacturing experiences.

Tour our facilities, get an inside look at state-of-the-art manufacturing technologies and more.

A place for expert insights, industry trends, and practical manufacturing tips from the Fathom team.

Find quick answers to common questions about our capabilities, processes, and getting started with Fathom.

Learn more about Fathom’s mission, people, and footprint across the U.S. We’re committed to excellence, innovation, and supporting our customers at every stage of the product journey.

Fathom is a U.S.-based advanced manufacturer built to serve engineers with speed, scale, and precision.

Stories, announcements, and milestones shaping Fathom’s role in modern manufacturing.

25+ processes, real production capacity, and a white-glove experience—Fathom delivers more than just parts.

Client

Guillermo del Toro

Industry

Entertainment

Capabilities

PolyJet

With an adoption of additive manufacturing, Fathom’s multi-step approach delivered custom, value-added solutions to achieve filmmakers’ creative vision.

The award-winning Guillermo del Toro’s Pinocchio (Pinocchio) reimagined stop-motion animation, incorporating mechanical components for many of the puppets to provide facial movement and lip sync when moved frame by frame.

This innovative approach to puppet fabrication paved the way for a more flexible performance that enabled Guillermo to direct this film in a unique way compared to previous stop-motion features by breathing life into the puppets as if they were live actors.

The use of stop animation required strict continuity for the mechanically operated puppets, especially for the intended shapes and colors of Pinocchio’s nose, head and eyes as well as Spazzatura’s muzzle.

Fathom employed a multi-step approach to achieve the creative vision for this animated feature. To ensure maximum precision for each print, Fathom defined print diver settings, controlled material batches, and quality control processes as part of the production plan. Voxel-level 3D printing also enabled the creation of color models in a 3D digital landscape, providing a seamless conversion to a 3D printed model with texture mapping. Color matching and texture was complex while calibrating the different machines was laborious, requiring an extensive validation process.

Fathom’s broad 3D printing capabilities and in-depth knowledge of current software tools created a manufacturing pipeline from animator to technology specialist to the studio.

The 3D printing techniques employed in the making of Pinocchio successfully conveyed the emotions of the characters and helped the animators achieve the nuances they sought.