Hand Safety Tool

-

CLIENT:

Hand Safety Tool

-

INDUSTRY:

Construction, Oil & Gas

-

CAPABILITIES USED:

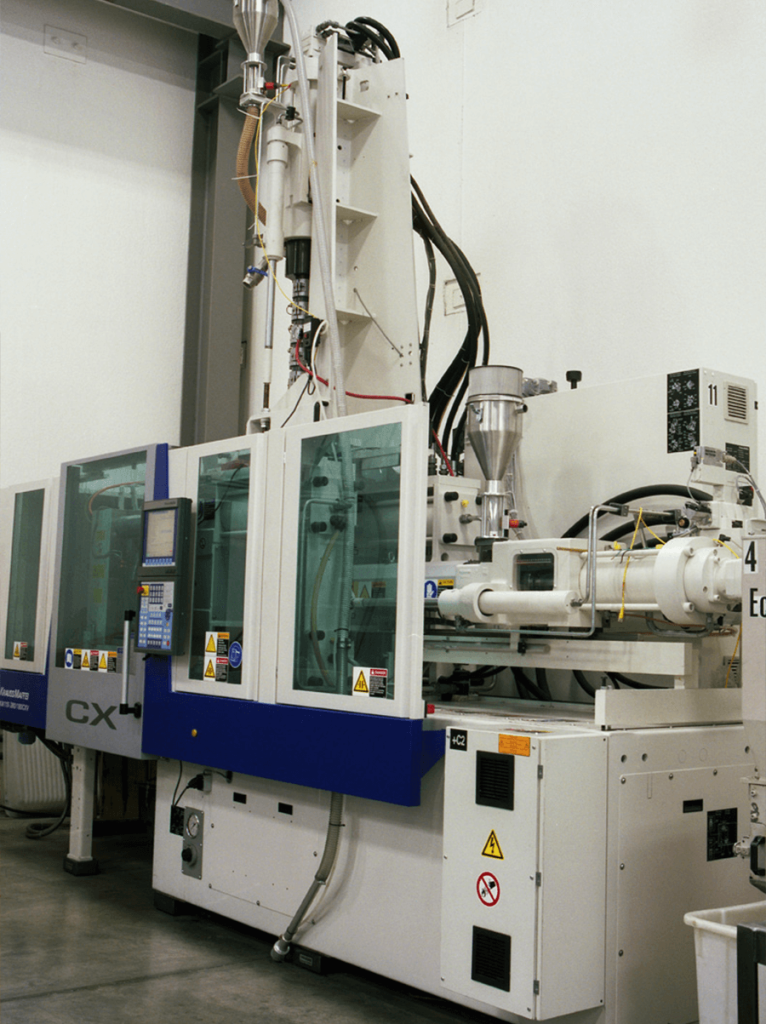

Injection Molding

Fathom is hiring for multiple positions across our nationwide sites! To see all open positions, click here

From prototyping to production, Fathom delivers precision manufacturing at scale. Explore our comprehensive suite of U.S.-based services—from CNC machining and molding to advanced metrology and outsourced solutions—trusted by leaders in aerospace, medical, robotics, and beyond. Every project is backed by expert support, strict certifications, and scalable technology.

Fathom provides full-spectrum manufacturing solutions tailored to your product journey—from early-stage concept to scalable production. Our services are built to accelerate timelines, reduce costs, and ensure quality across every phase.

Helping you solve your biggest manufacturing challenges – with White Glove Service

Leverage our deep engineering expertise and white-glove support from prototype to production to bring your new products to market faster.

Tariffs. Instability. Margin Pressure. Fathom Edgeworks was built to outsmart the chaos and outprice the competition.

We specialize in high-stakes sectors where precision, speed, and reliability matter most. Explore how Fathom supports innovation across regulated and fast-moving industries.

High-precision where performance and compliance matter most.

Quality controls for regulated environments.

For tight tolerances, reliability, and scale.

The consistency and control for advanced fabrication.

Precision for reliability, repeatability, and production readiness.

Accelerating ICT infrastructure builds with less risk—from prototype through ramp.

All other industries beyond our five primary markets.

Stay ahead with expert content, guides, and case studies that support smarter decisions and better manufacturing outcomes.

Fathom customers love our hands-on approach to engineering and production. Read the stories.

Check out our industry events, facility tours, and expert-led manufacturing experiences.

Tour our facilities, get an inside look at state-of-the-art manufacturing technologies and more.

A place for expert insights, industry trends, and practical manufacturing tips from the Fathom team.

Find quick answers to common questions about our capabilities, processes, and getting started with Fathom.

Learn more about Fathom’s mission, people, and footprint across the U.S. We’re committed to excellence, innovation, and supporting our customers at every stage of the product journey.

Fathom is a U.S.-based advanced manufacturer built to serve engineers with speed, scale, and precision.

Stories, announcements, and milestones shaping Fathom’s role in modern manufacturing.

25+ processes, real production capacity, and a white-glove experience—Fathom delivers more than just parts.

CLIENT:

Hand Safety Tool

INDUSTRY:

Construction, Oil & Gas

CAPABILITIES USED:

Injection Molding

The Hand Safety Tool Company LLC was on a mission to grow its product line while managing production costs. To scale efficiently while managing expenses and supply chain risks, it utilized Fathom’s overseas and domestic injection molding capabilities.

The Hand Safety Tool Company’s flagship product, the ShoveIt® Hand Safety Tool, is a push/pull pole with a V-shaped plastic head design that enables users to guide loads, move and position objects, as well as grab slings and taglines without physically placing hands on the item. The part’s design required glass-filled nylon injection molding and heat staking of multiple threaded inserts—making it both material-intensive and technically demanding.

Initially, overseas production of this part was the most affordable route. However, with a small internal team and limited logistics resources, The Hand Safety Tool Company’s ultimate goal was to transition all production to 100% U.S.-based manufacturing.

The Hand Safety Tool Company selected ICOMold by Fathom for its competitive pricing, excellent customer support and the ability to transition to domestic production as production volume increased. This level of tailored support allowed The Hand Safety Tool Company team to stay focused on product innovation while gradually reshaping its supply chain – from overseas tooling and initial production to hybrid production (export tools built overseas and shipped to the U.S. for part production) and finally fully domestic tooling and production.

Since 2018, The Hand Safety Tool Company has grown from a single product to a line of nine specialized tools. With ICOMold by Fathom’s tailored manufacturing support, the company has been able to:

Successfully manage its per-part production costs through flexible sourcing.

Cost-effectively scale part production so it could expand its product line.

Streamline its inventory management and fulfillment times by transitioning from overseas to 100% domestic sourcing.

Fathom scaled to meet the company’s needs – from overseas to domestic injection-molded parts

The ShoveIt tool in action – keeping the worker’s hands out of harm’s way

The ShoveIt tool is used to push heavy objects, too

The part’s design required glass-filled nylon injection molding and heat staking of multiple threaded inserts