Textron

-

Client

Textron

-

Industry

Aerospace

-

Capability

3D Printing

Fathom is hiring for multiple positions across our nationwide sites! To see all open positions, click here

From prototyping to production, Fathom delivers precision manufacturing at scale. Explore our comprehensive suite of U.S.-based services—from CNC machining and molding to advanced metrology and outsourced solutions—trusted by leaders in aerospace, medical, robotics, and beyond. Every project is backed by expert support, strict certifications, and scalable technology.

Fathom provides full-spectrum manufacturing solutions tailored to your product journey—from early-stage concept to scalable production. Our services are built to accelerate timelines, reduce costs, and ensure quality across every phase.

Helping you solve your biggest manufacturing challenges – with White Glove Service

Leverage our deep engineering expertise and white-glove support from prototype to production to bring your new products to market faster.

Tariffs. Instability. Margin Pressure. Fathom Edgeworks was built to outsmart the chaos and outprice the competition.

We specialize in high-stakes sectors where precision, speed, and reliability matter most. Explore how Fathom supports innovation across regulated and fast-moving industries.

High-precision where performance and compliance matter most.

Quality controls for regulated environments.

For tight tolerances, reliability, and scale.

The consistency and control for advanced fabrication.

Precision for reliability, repeatability, and production readiness.

Accelerating ICT infrastructure builds with less risk—from prototype through ramp.

All other industries beyond our five primary markets.

Stay ahead with expert content, guides, and case studies that support smarter decisions and better manufacturing outcomes.

Fathom customers love our hands-on approach to engineering and production. Read the stories.

Check out our industry events, facility tours, and expert-led manufacturing experiences.

Tour our facilities, get an inside look at state-of-the-art manufacturing technologies and more.

A place for expert insights, industry trends, and practical manufacturing tips from the Fathom team.

Find quick answers to common questions about our capabilities, processes, and getting started with Fathom.

Learn more about Fathom’s mission, people, and footprint across the U.S. We’re committed to excellence, innovation, and supporting our customers at every stage of the product journey.

Fathom is a U.S.-based advanced manufacturer built to serve engineers with speed, scale, and precision.

Stories, announcements, and milestones shaping Fathom’s role in modern manufacturing.

25+ processes, real production capacity, and a white-glove experience—Fathom delivers more than just parts.

Client

Textron

Industry

Aerospace

Capability

3D Printing

Fathom used additive technology to build a lightweight, hand-held testing device for the aviation industry. This complex part required tight tolerances, multiple inserts and extensive post-processing. All finishing and assembly was done under one roof.

The customer asked Fathom to build a complex housing to which multiple instruments and electronics would be attached for a handheld ground testing device. Several surfaces of this part required tight tolerances, post-machining and installation of multiple threaded inserts.

The customer was also looking for assistance in lightweighting this part to improve its ergonomics. In addition, the housing also needed to be finished with an EMI coating to shield the device’s sensitive instruments and signals from interference.

DFAM Analysis // Fathom’s experienced engineering team performed a detailed DFAM analysis, which uncovered several opportunities for improvement and helped prevent hidden problems during production. The design modifications suggested by the Fathom team included reducing the weight of the part by 10% and the cost of production by 15%.

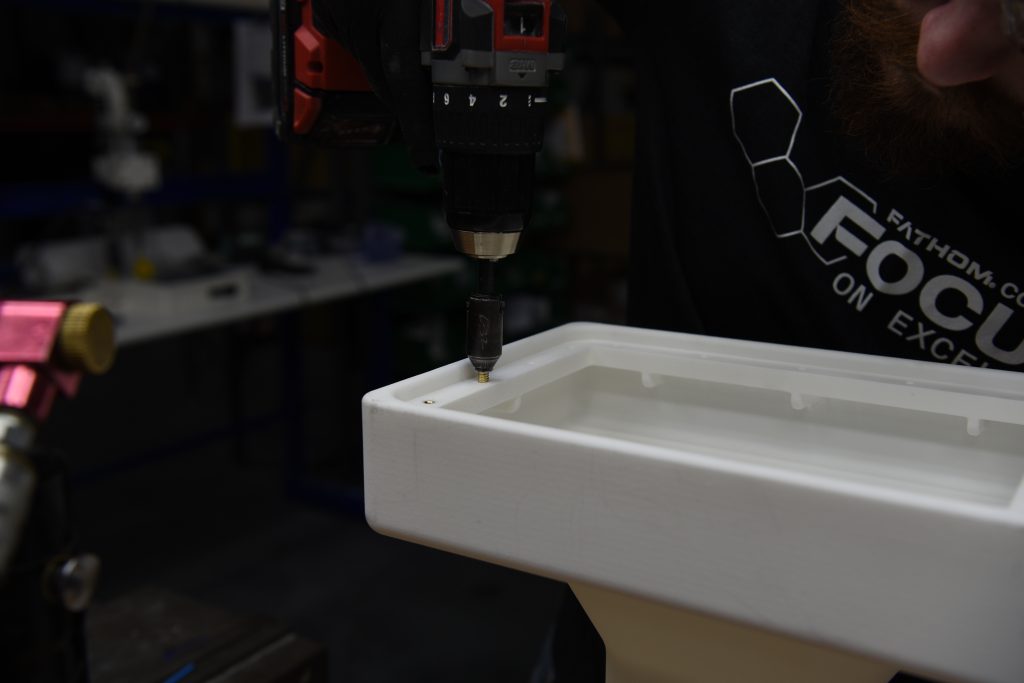

These housings were 3D printed to exact tolerances using SLS made of glass-filled nylon. This material provides excellent structural rigidity and impact resistance. Several of the part’s surfaces were post-machined to meet the customer’s requirements. Next, the Fathom production team sanded, primed and painted the housings with a high-gloss, bright red finish. An EMI coating was then applied. Finally, the Fathom team installed multiple threaded inserts for 10/32-in. screws, to which instruments and electronics were attached. Fathom also did some assembly work on these devices.

Fathom provided the customer with a turnkey solution that included printing, machining, painting, assembly and inspection and was 99% accurate to quote.

Fathom was able to complete all four operations in-house, saving Textron several weeks compared to its previous supplier and their external partners.