Product Development – Accelerated

-

Client

VSi Parylene

-

Industry

Construction, Oil & Gas

-

Capability

Metal Cutting & Forming

Accelerate Manufacturing Innovation

Reduced Product Development 50%

Supplier Consolidation

Coating Equipment Manufacturer Feels the Need for Speed

Fathom’s integrated, technology-agnostic approach and rapid response team enabled a customer to condense its product development cycle in half.

The Problem

-

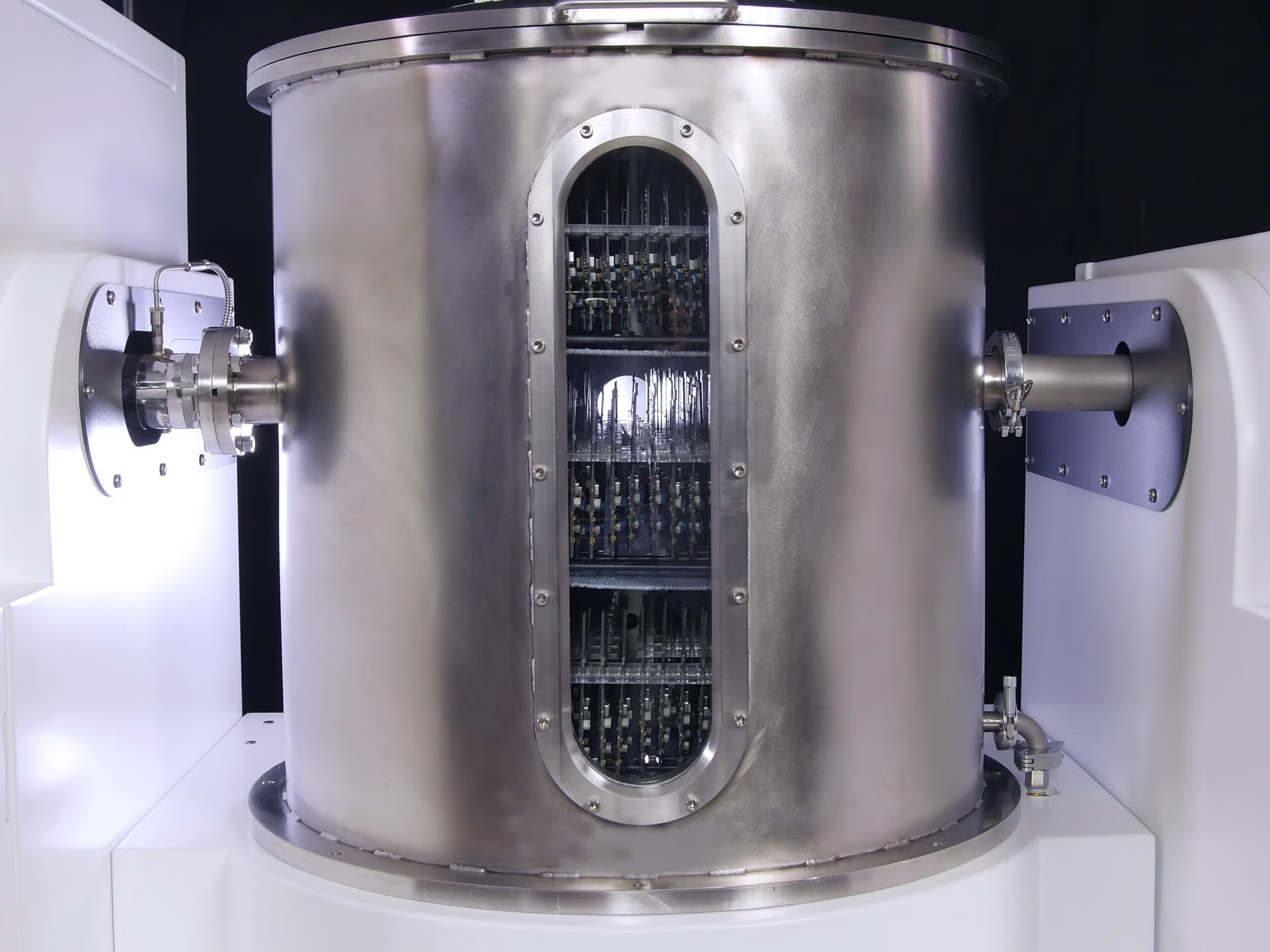

VSi Parylene (VSi) provides advanced protective coating technologies for various industrial and consumer electronics, aerospace and medical applications. In developing its next generation parylene conformal coating system, VSi sought a unified partner with extensive manufacturing capabilities, engineering expertise and quality assurances for the launch of its robust POD Factory machine.

-

VSi wanted the aesthetic design of the POD machines to reflect the sophistication, precision and quality of its equipment and brand. But their CAD file revealed some issues that could seriously impact the manufacturability of the new machine. VSi insisted on preserving the inspiring and unique aesthetics of the design and was looking for an advanced manufacturing partner that could help them provide beautiful and scalable machines.

The Solution

Fathom drew upon its highly trained technical staff to provide timely feedback on the geometry of the CAD file to ensure the design for manufacturability. In examining the needs of the customer, Fathom collaborated with VSi to validate the engineering aspects of the new system and defined which of its manufacturing processes would best achieve the desired outcome.

The Results

-

Speed Time to Market // Fathom’s integrated, technology-agnostic approach and rapid response team enabled VSi to take delivery of the entire mechanical portion of the system within 8 weeks, condensing the product development cycle by approximately 50%.

-

Supplier Consolidation // VSi was able to consolidate their supply chain by sourcing through a single certified supplier. This adaptive, one-stop solution significantly increased operating efficiencies and provided a differentiated customer experience.

-

Accelerate Manufacturing Innovation // Multiple fast iterations in developing the industrial-sized POD system sparked innovation of a new complementary product, the POD Access machine, enabling VSi to increase scalability and expand the size of its total addressable market.

-

Hybridized Manufacturing Services // In total, Fathom successfully produced and assembled more than 815 high-quality components requiring over 760 distinct manufacturing steps.