Fathom’s white-glove service is unique in the contract manufacturing world. Most of our competitors rely on AI-driven, automated quoting and basic DFM feedback. When you’re dealing with highly-engineered products, that’s not enough.

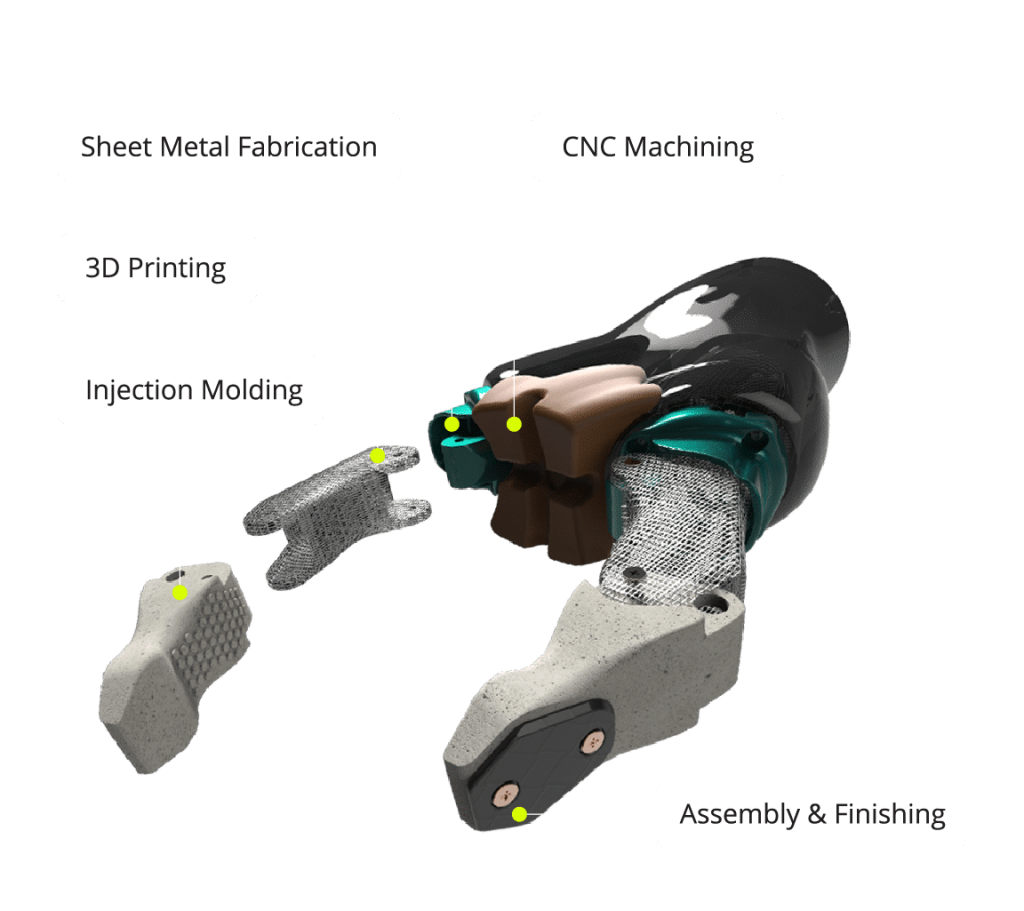

Preparing your part design for production is a complex process with many variables. It often involves trade-offs, critical thinking and even a bit of creativity to solve design and production problems up front – before you run into expensive tooling and production problems. Plus there are often part geometry-specific “gotchas” you need to be aware of and solve for.

The most reliable path to consistent project success is with a hands-on, engineering-led approach. That’s the foundation of White Glove Service at Fathom. Our rigorous process ensures every project receives the technical guidance and care it deserves.

With decades of hands-on experience across additive manufacturing, injection molding, CNC machining and sheet metal fabrication, we anticipate challenges early and provide practical solutions that keep your projects on track. The result is a more collaborative, transparent process that leads to better products and faster launches.