Our Customers

When Exceptional Accuracy Is A Must, Count On Dahlquist Machine By Fathom

Do you need production quantities of high-precision CNC machined metal and plastic parts on a Just-In-Time (JIT) or Kanban basis?

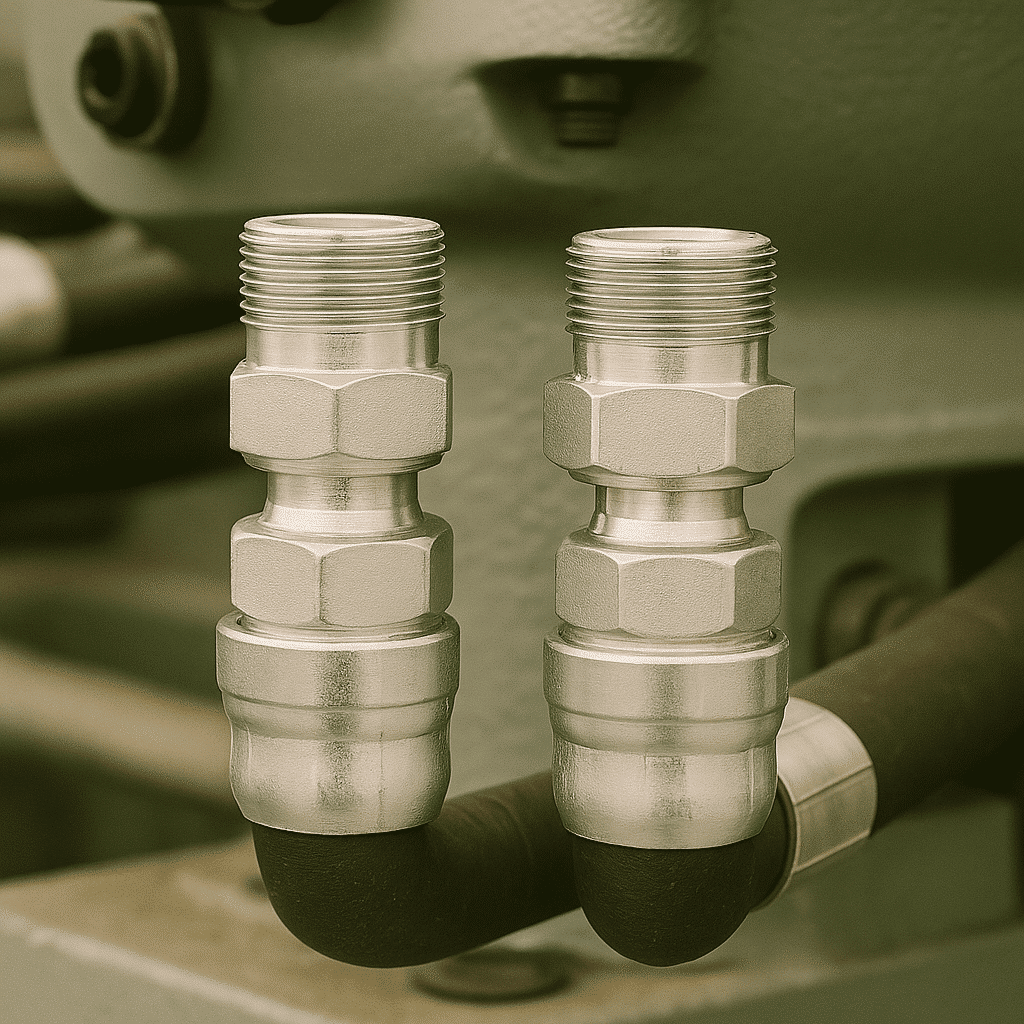

The team at Dahlquist Machine by Fathom has been building turned and milled parts that are used in some of the world’s most sophisticated measurement and diagnostic devices. In these applications, nothing less than exceptional accuracy will do.

Our customers love our relentless focus on pinpoint machining accuracy and uncompromising part quality. We offer:

-

High-precision metal and plastic CNC machining

-

Short- to medium-production runs

-

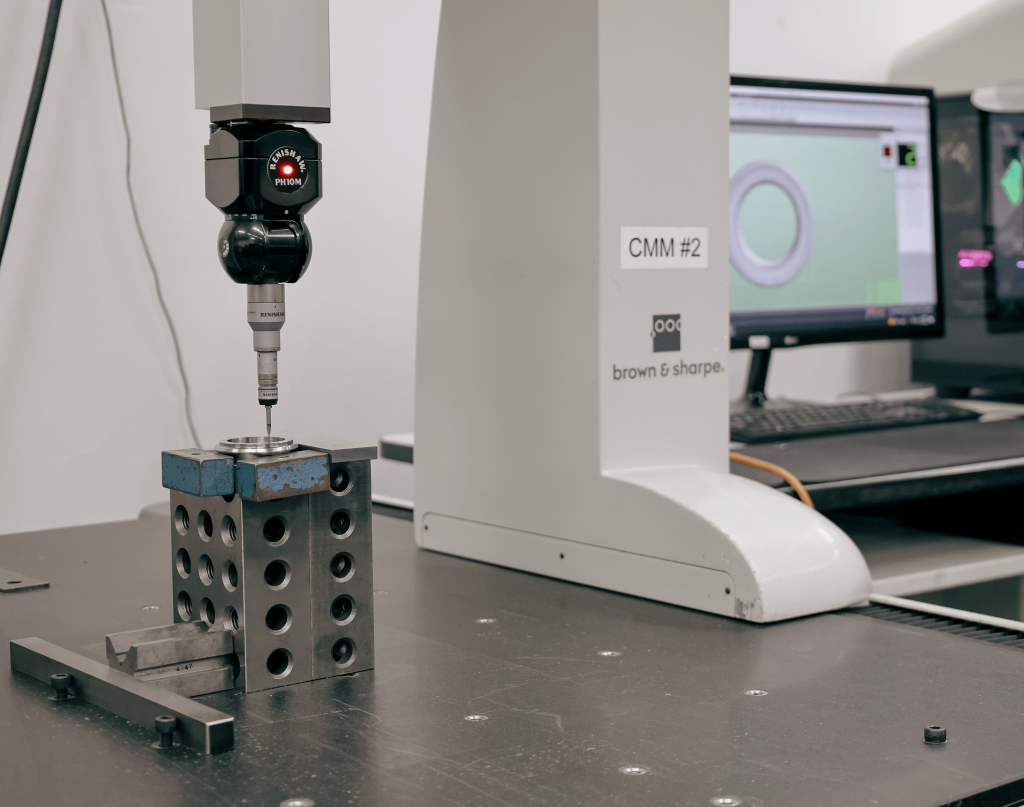

Strict quality control standards

-

100% on-time delivery

-

Stocking programs on request

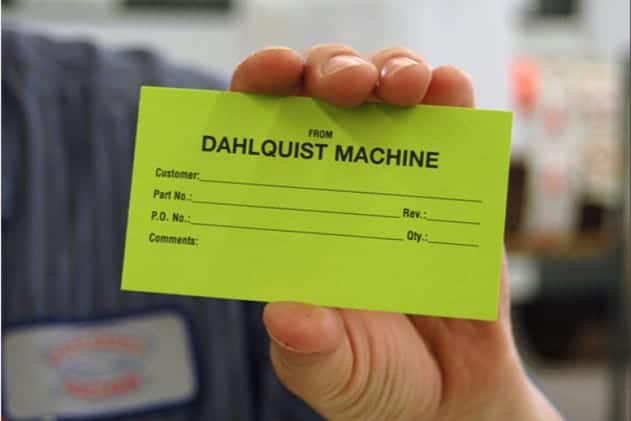

Each of our part orders ships with the Dahlquist Green Card – our guarantee that your parts were manufactured to the highest possible standards.

Quality CNC Machining, Guaranteed

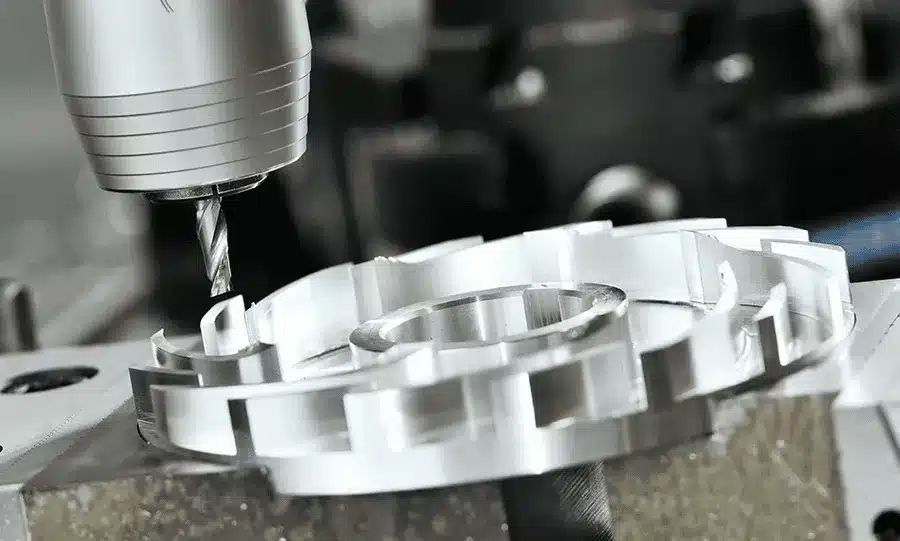

Dahlquist by Fathom specializes in short- to medium-run quantities of tight-tolerance parts that require precision machining of light metals, aluminum and plastic.

We’re a nominal shop that uses as little tolerance as possible when machining parts. For a tolerance of plus or minus 0.005 in., we machine to 0.001 in. That means you don’t need to worry about tolerance stack-ups when mating our components with other parts.

CNC Milling

We have over 20 horizontal and vertical milling machine centers, including a new 5-axis machine that enables us to build your complex geometries up to a table size of 20 x 40 in. Our multi-axis machining equipment enables us to meet your most complex milling requirements.

CNC Turning

We operate 8 CNC lathes, which can machine parts up to 8 in. diameter. All are equipped with sub-spindles, live tooling and Y-axis for milling and bar feeders.

Work with us and experience the Dahlquist by Fathom Difference – a step above other CNC machining companies.

A Passion for Quality

Green Tag // At Dahlquist Machine by Fathom, we’re proud to produce high-quality parts with American precision. Every product that leaves our door is labeled with a Green Tag. We guarantee that your parts have been built to your specifications, with the highest level of quality.

Quality // Our quality team utilizes touch and vision equipment to test part specifications, including two Zeiss CMM machines, a Micro Vu Vision machine and numerous digital and standard gages that are operated in a climate-controlled inspection lab.

Certification // ISO9001:2015

Customer Testimonials

Why Our Customers Trust Dahlquist by Fathom

100%

30+

ISO 9001

50+

Industries Served

-

Medical Diagnostics

-

Analytical Equipment

Applications

-

Medical Diagnostic Devices

-

Measurement Devices

-

Coordinate Measuring Machines (CMMs)

See What Dahlquist by Fathom Can Build For You

Download our linecard for an overview of our precision CNC capabilities and the engineering expertise that sets our team apart.

Service Area

While we partner with companies nationwide, our Ham Lake location also proudly supports many customers throughout the region, including:

St. Paul | Rochester | Bloomington | Hudson | Maple Grove | Plymouth | Brooklyn Park | Woodbury | Lakeville | St. Cloud | Blaine | Eagan | Eden Prairie | Coon Rapids | Minnetonka

Why Choose Dahlquist by Fathom for Your Machining Needs?

During the last 50 years, Dahlquist Machine by Fathom has developed a reputation for quality and integrity. We have maintained 100% on-time delivery for over 25 years.

Our team’s exceptional dedication to quality and craftsmanship ensures that we provide the best service and parts to our customers. We do what we say we’re going to do! That’s increasingly rare today and sets us apart from other CNC machining companies.

Let us help you solve your complex machining challenges. Request a quote today!