The Manufacturing Exchange

Please join us for a half-day workshop for engineers & manufacturing leaders

🗓️ Wednesday, September 24, 2025

📍1050 Walnut Ridge Rd. Hartland, WI 53029

⏰ 3:00 – 6:00 PM

Ideas, Insights & Innovation in Action

Manufacturing is at a crossroads. From supply chain volatility to workforce shortages and complex handoffs from engineering to production, the gaps are widening and the need for bold solutions has never been greater.

Join us for a half-day workshop designed to equip you with forward-thinking strategies from four of our industry’s most influential voices. Get a rare inside look at one of the Midwest’s most advanced manufacturing facilities. You’ll see how Fathom’s engineering-first, white-glove approach transforms the contract manufacturing experience.

Who You’ll Meet

Jake Hall

Jim Mayer

Meaghan Ziemba

Chris Luecke

What You’ll Learn

Gain insights into the trends challenging and shaping our industry

Exchange ideas with peers and influencers in a relaxed, fun setting

Join a live podcast recording with local manufacturing and industry experts

Get an exclusive look at our modern contract manufacturing facility

Schedule of Events // The Agenda

We’ve designed this event to bring together the best and brightest minds in manufacturing, intimate small-group discussions on key topics, a unique facility tour and networking opportunities – all in a knowledge-filled, half-day package. The Manufacturing Exchange offers a wealth of value to anyone who is committed to making a difference in manufacturing.

3:00 – 4:30 PM – Facility tours and breakout sessions

4:30 – 5:30 PM – Panel discussion on the main stage, ice cold beer and hors d’oeuvres

5:30 – 6:00 PM – Networking and wrap-up

Here’s what we’ve prepared for you:

Breakout Sessions //Participate in discussions about key topics like talent and recruitment and sourcing and supply chain challenges. Exchange ideas and experiences with our experts and your peers in relaxed, small group settings.

Panel Discussion // This session will be hosted by leading voices in the manufacturing industry and will feature executives from leading Milwaukee manufacturers. It will also be a live recording of Chris Luecke’s Manufacturing Happy Hour.

Facility Tour // Did you know that Fathom offers more manufacturing technologies than any other U.S. contract manufacturer? This isn’t your typical factory tour. It’s a rare opportunity to see parts at each stage of their production journey and learn from the people who make them. Don’t miss it!

Networking // Grab an ice-cold beer and some delectable Milwaukee treats and network with your peers and our special guests. It’s another awesome opportunity to share ideas and experiences.

Breakout Session // Closing the Gap: Sourcing & Supply Chain

FACILITATORS: Chris Luecke and Jake Hall

As the global manufacturing environment becomes increasingly volatile, new strategies are needed to navigate it successfully. The ideas discussed in this breakout will help you achieve smoother sailing with your overseas manufacturing projects.

- OEM and supplier collaboration

- De-risking sourcing

- Reshoring

- Tariffs

Breakout Session // Breakout Session // Closing the Gap: Recruitment & Talent

FACILITATORS: Jim Mayer and Meaghan Ziemba

Older workers are retiring. Young people are avoiding manufacturing as a career. During this breakout, you’ll learn about strategies that are working to help close the manufacturing employment gap.

- Attracting youth to manufacturing

- AI technology

- Culture

- The future workforce

Panel Discussion // The Manufacturing Gap: Talent, Technology & Transformation

LIVE MANUFACTURING HAPPY HOUR PODCAST WITH: Chris Luecke and special guests

Our diverse panel of experts will explore the many gaps that are challenging our industry today:

- The loss of engineering talent to downsizing

- Attracting young people to manufacturing

- Gaps in technology adoption that limit growth opportunities

- Gaps in supply chain resilience

- Strategy gaps that prevent companies from competing effectively

- And more

Our panelists include leading voices in the Milwaukee manufacturing space and all four of our industry experts. You’ll take away ideas and strategies you can use to attack these challenges head-on.

BONUS: You’ll be part of a live taping of Chris Luecke’s Manufacturing Happy Hour podcast. You’ll also get to enjoy cold beer and tasty hors d’oeuvres during our Manufacturing Exchange happy hour!

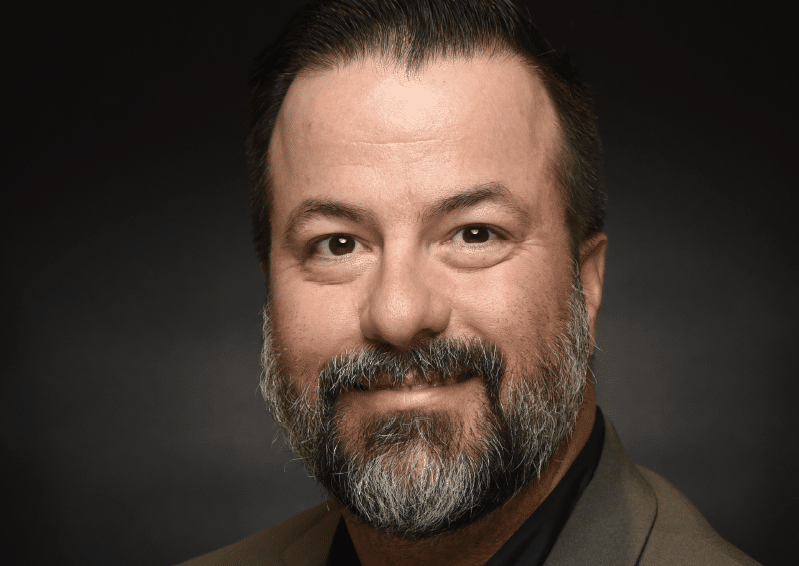

Our Panelists

This group will provide a diverse set of perspectives on key issues facing your business today:

Matt Weinheimer

Senior Manager, Global Advanced Manufacturing Engineering

𝗠𝗶𝗹𝘄𝗮𝘂𝗸𝗲𝗲 𝗧𝗼𝗼𝗹

Matt leads global teams bringing next-generation battery technology into production. He’s passionate about solving complex manufacturing challenges and driving technological innovation into the manufacturing space.

Tim Fredericks

Innovation Manager

𝗥𝗼𝗰𝗸𝘄𝗲𝗹𝗹 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻

Tim helps teams turn emerging technology into practical solutions for manufacturing. With deep experience in technology implementation and a growing focus on innovation practices, he works across functions to drive usability, scalability and value in both internal initiatives and customer-facing products.

Christine VanDerGeest

Partner & Vice President

𝗔𝗪𝗜 𝗠𝗲𝘁𝗮𝗹 𝗙𝗮𝗯𝗿𝗶𝗰𝗮𝘁𝗶𝗼𝗻

Chrissy brings over 15 years of expertise in operations and client relations to her role at AWI. Headquartered in Franksville, Wisconsin, the company delivers custom metal fabrication solutions for the medical, pharmaceutical, food and industrial sectors.

Karl Held

Business Development Manager/Owner

𝗡𝗲𝘄 𝗕𝗲𝗿𝗹𝗶𝗻 𝗣𝗹𝗮𝘀𝘁𝗶𝗰𝘀

From the shop floor to the leadership table, Karl Held has spent nearly two decades growing with New Berlin Plastics. His career has spanned production, sales and marketing, giving him a deep understanding of what it takes to build resilient operations and strong customer relationships.

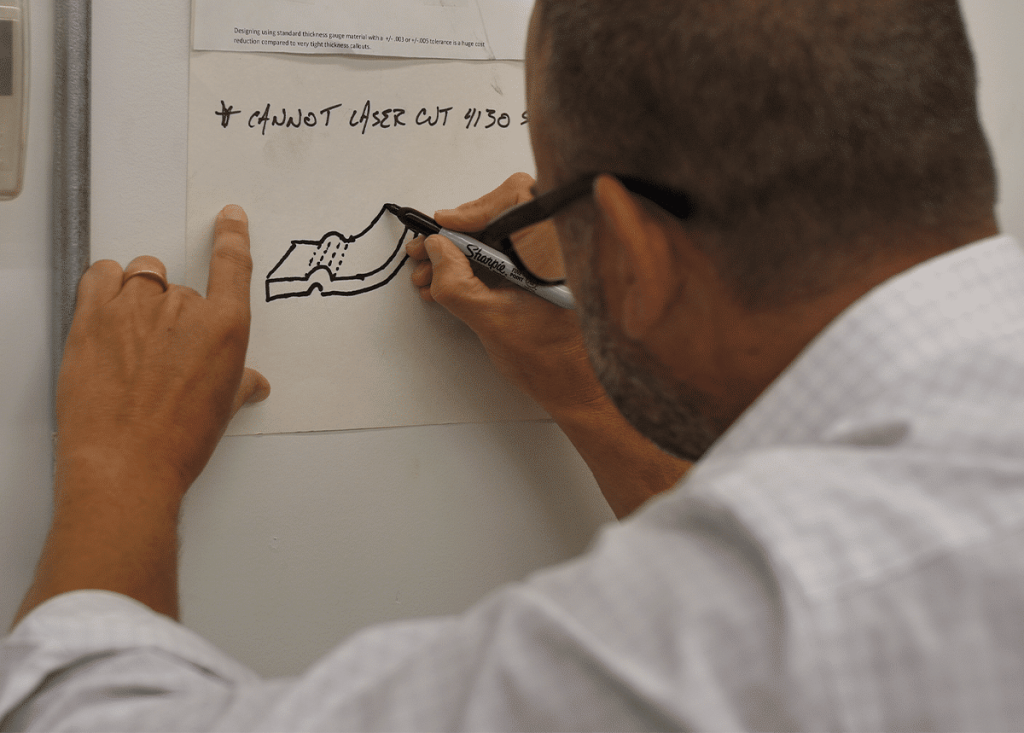

Facility Tour // Not Your Ordinary Tour

During a guided tour of our Hartland facility, you’ll stop at eight workstations, where you’ll explore cutting-edge processes, from additive manufacturing and CNC machining to finishing and assembly. They will be explained by the experts who run them every day.

You’ll also have a unique opportunity to follow the journey of real-life parts from concept to completion, giving you a deeper understanding of the end-to-end processes we manage at our flagship manufacturing facility.

- Learn how engineering expertise helps our customers bridge the gap between design intent and production reality

- Experience our comprehensive design-to-production process in action

- Gain practical engineering insights into manufacturing and finishing processes

Who Should Attend

Are you a savvy engineer or manufacturing leader? This event is designed for you! You’ll also have a unique opportunity to learn from and network with industry leaders. If you have questions about manufacturing trends and challenges, this is the place where you can get answers from industry experts.

You should join us if you are a:

- Design or mechanical engineer

- Procurement manager

- Manufacturing leader

- Manufacturing production manager

- Educator working to address the shortage of manufacturing workers

- Anyone concerned about manufacturing trends

Why is This a Don’t-Miss Event?

You’ll leave this workshop energized with ideas and strategies you can use to make a difference in your manufacturing environment, including:

- Fresh insights into the forces and trends redefining manufacturing

- New options for flexible sourcing in an uncertain global environment

- An expanded understanding of the design-to-production process and how to streamline it

- New connections with peers who share your challenges and vision

Don’t miss this unique opportunity to arm yourself with knowledge and ideas that can help you mitigate the challenges you face and uncover new opportunities for growth.

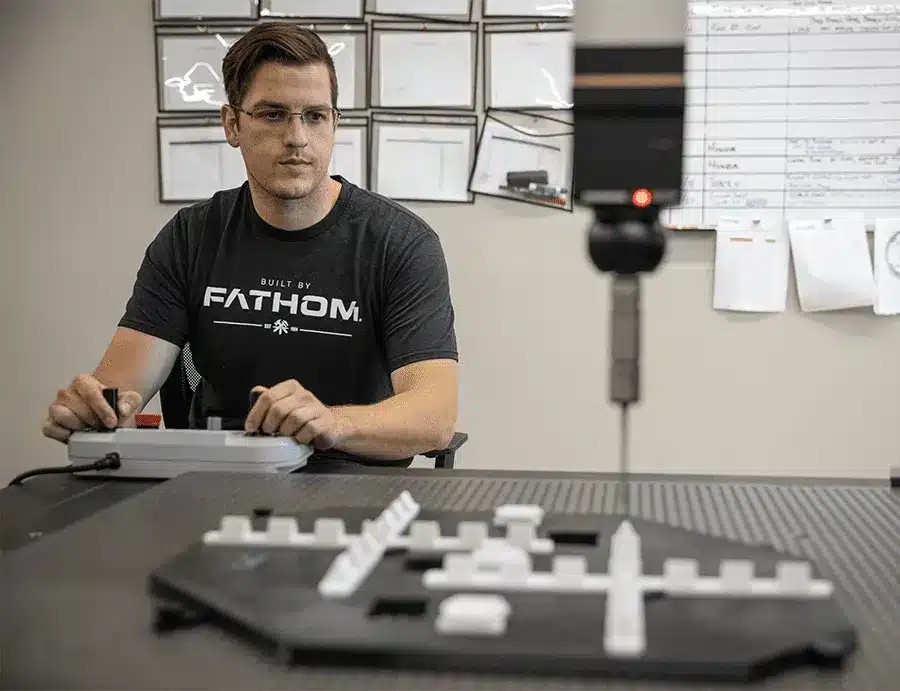

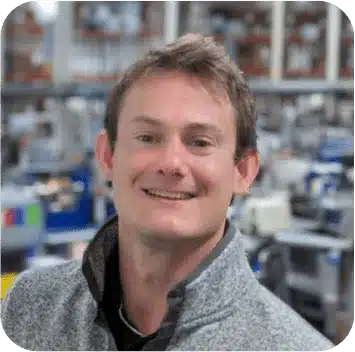

Snapshots of Our Successful Event

Attendees loved the facility tour, where they got to see additive manufacturing, CNC machining and post-processing operations up close – and saw how parts moved through the manufacturing process. They also had opportunities to learn from industry experts and network with their peers.