Our Aerospace Customers

Every Micron. Every Milestone. Every Mission Depends on It.

In aerospace and defense, the smallest detail can decide the biggest outcomes. A tolerance off by a fraction, a delay in part production – suddenly programs stall, costs spike and risk multiply.

Sound familiar?

-

Fast Programs, Slow Suppliers: Your timeline accelerates. Their response doesn’t.

-

Design-to-Production Disconnect: You need DFM input early, not after the fact.

-

Lead Times That Drag: Quality slips and schedules stretch with them.

-

Regulatory Red Tape: Without AS9100, ISO9001 and ITAR compliance, you’re grounded.

You can’t afford to chase vendors who can’t keep pace or scale with your program demands. You need a manufacturing partner built for aerospace – a team that’s agile, certified and relentless about getting it right the first time. Because in this industry, almost right is completely wrong.

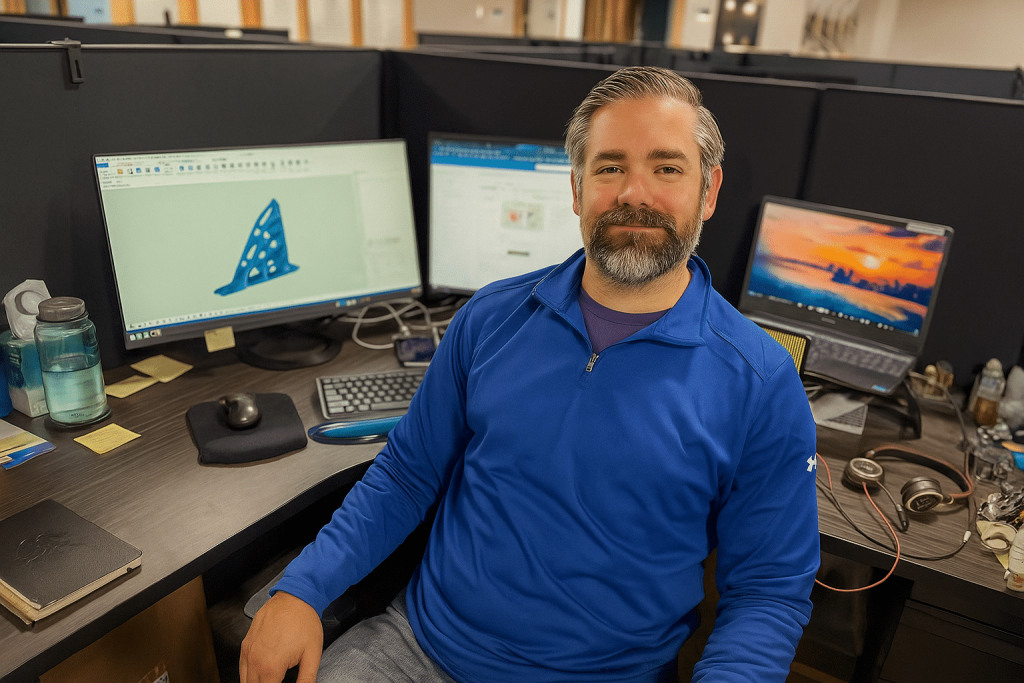

Human-First Manufacturing

From the moment you kick off your project, you’ll have access to a team of experienced professionals who will help you through every step of the process, from part design and prototyping to scaling up production. It’s all part of our white glove approach to meeting your needs.

Account Manager

Applications Engineer

Project Coordinator

Customer Success Representative

Our Expertise – By the Numbers

6300+

25+

AS9100

ITAR

How Do Aerospace Companies & Defense Contractors Use Fathom?

Unmatched Breadth of Technologies

We offer more advanced manufacturing technologies than any other contract manufacturer. That enables aerospace and defense companies to get more of their needs met with one supplier.

Rapid Prototyping

We’re set up to manage the rapid prototyping needs of our customers in these industries. Our expert engineers help them quickly test, iterate and finalize their part designs for production.

Product Lifecycle Support

We support their needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes as well as bridge production and full production. We specialize in low-volume/high-mix projects.

Engineering & Design Support

We take a hands-on, white glove approach to DFMs to ensure that all of our customers’ potential part design issues are identified and solved early in the design process. We help them optimize their part designs, production processes and material selections for the best results, at the best price.

Quality Assurance

At Fathom, our commitment to in-house inspections enables us to turn around parts quickly, including CMM validation, surface inspections and tensile strength testing. In addition, we have a proven ability to comply with our customers’ specific process, material and workmanship standards.

Comprehensive Capabilities for Aerospace & Defense

With a portfolio of 25+ advanced manufacturing technologies, we’re able to provide you with blended solutions that meet your exact requirements. It’s all backed by our white-glove, hands-on service. From the battlefield to outer space, we’ve got you covered.

Additive Metal Expertise

From rocket nozzles to light-weight brackets for aircraft interiors, we bring an unmatched depth of expertise to producing prototype and production parts using Direct Metal Laser Sintering (DMLS), a popular metal additive technology. We also offer in-house post-processing of 3D-printed metal parts, including media blasting and post-machining.

Complex Metal Forming

Our sheet metal experts can help you optimize your designs for production, from large exterior panels to small, complex brackets, connectors and contacts. We can meet all your requirements, from sheet metal fabrication and precision forming of small, complex parts. We also offer a full range of finishing options for your formed metal parts.

Machining of Tough Materials

Our facilities do some of the most advanced, precise CNC machining work in the country, including tough materials like titanium, Inconel and hardened steel. With decades of expertise across multiple facilities, we’re CNC problem-solvers.

Expertise Building Parts for Tough Environments

From drone and military rifle components to spacecraft and satellite parts, what we build gets used in some of the world’s most demanding environments. Our certifications, which include ISO9001, AS9100 and ITAR, ensure that our parts are built to go the distance.

Light-Weighting Expertise

In the aerospace industry, reducing weight is a critical design requirement. We have decades of experience helping our customers replace solid walls in their part designs with lattices that are just as strong but significantly reduce weight, printing time and cost.

Common Aerospace Applications

We have years of experience meeting the world’s most demanding aerospace and military specifications for a variety of parts.

-

Aircraft interiors

-

Spacecraft and satellite components

-

Telecommunications components

-

Optical system components

-

Military rifle components

-

Military vehicle components

-

Military UAV and drone components

-

High-performance tools and fixtures

Why Choose Fathom for Your Aerospace & Defense Projects?

Whether your products are used on the ground, in the air or in space, we have the technologies, capacity and expertise to help you achieve your objectives.

-

Application Expertise

We understand the environments that your parts are exposed to, from the ground and air to space. We’ll recommend materials, processes and finishing options to ensure your parts will go the distance.

-

Your Lifecycle Partner

We can support your needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes to verify fit, finish and functionality to bridge and full production.

-

Unmatched Breadth of Manufacturing Technologies

We offer more advanced manufacturing technologies than any other contract manufacturer, plus a wide variety of in-house finishing services. This combination enables you to simplify your supply chain and your supplier base.

-

Track Record of Success

We have a long track record of success delivering high-quality parts to a variety of aerospace companies, military agencies and other organizations that serve these cutting-edge industries. From “high-rel” satellite components to aircraft interiors, we’re a trusted partner of integrated manufacturing solutions to leading companies in the aerospace and defense industries.

-

Relevant Certifications

Our certifications include:

- AS9100 Rev. D

- ISO 9001:2015

- NIST 800-171

- ITAR

In addition, we have a proven ability to comply with customer-specific process, material and workmanship standards.