ICT & Energy Manufacturing

Our ITC & Energy Customers

Are Capacity Constraints Giving You Headaches?

We can help.

When you get hit with a massive order from a leading customer, you need a reliable supplier that can meet your overflow needs – and keep your projects moving on a fast track.

But finding partners who have available capacity to help you with these urgent needs has been an ongoing challenge. Long lead times are unacceptable.

Your customers are impatiently waiting. You need parts – now!

Fathom has the manpower, expertise and capacity to help you keep your critical prototyping and production programs on track.

Start Your Project with a Trusted Manufacturing Partner

Let’s Get Started on Your Project

Every quote is reviewed by an experienced engineer to ensure optimal design, materials and manufacturability, so your part gets made right, the first time.

Human-First Manufacturing

From the moment you kick off your project, you’ll have access to a team of experienced professionals who will help you through every step of the process, from part design and prototyping to accelerating production. It’s all part of our white glove approach to meeting your needs and helping ensure the success of your production and new product development programs.

Account Manager

Applications Engineer

Project Coordinator

Customer Success Representative

Our Expertise – By the Numbers

1000+

5,000

25+

ISO 9001

How Do ITC & Energy Manufacturers Use Fathom?

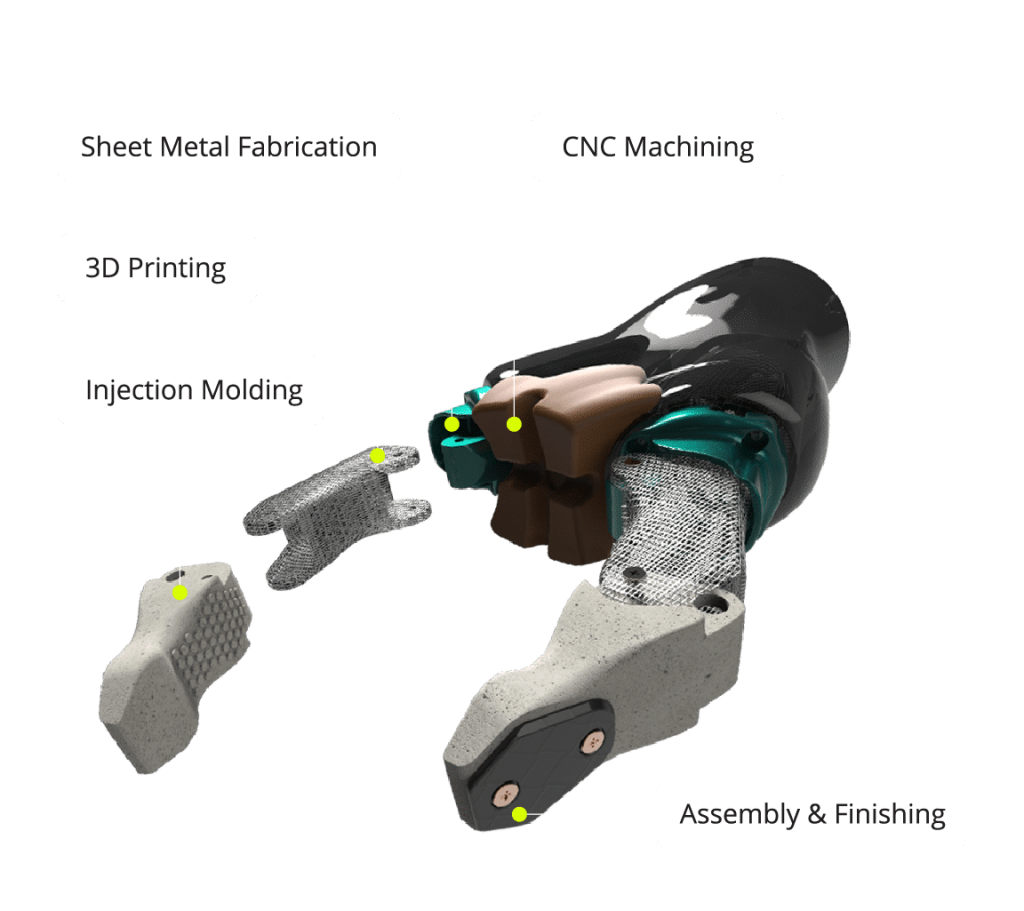

Unmatched Breadth of Technologies

We offer more advanced manufacturing technologies than any other contract manufacturer. That enables you to get more of your needs met with one supplier.

Rapid Prototyping

We’re optimized to manage the rapid prototyping needs of our customers. Our expert engineers will help you quickly test, iterate and finalize your part designs for production.

Product Lifecycle Support

We’ll support your needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes as well as bridge production and full production. We specialize in low-volume/high-mix projects – ideal for new platform launches.

Engineering & Design Support

We take a hands-on, white glove approach to DFMs. That helps ensure that all of your potential part design issues are identified and solved early in the process. We’ll help you optimize your part designs, production processes and material selections for the best results, at the best price.

Quality Assurance

Fathom’s ISO 9001:2015 compliance means that Fathom is a safe place to put your overflow projects. Our commitment to in-house inspections enables us to turn around parts quickly, including CMM validation, surface inspections and tensile strength testing.

Comprehensive Capabilities for the ITC & Energy Industries

With a portfolio of 25+ advanced manufacturing technologies, we’re able to provide you with blended solutions that meet your exact requirements. It’s all backed by our white-glove, hands-on service.

Complex Metal Forming

Our sheet metal experts can help you optimize your designs for production, from large exterior panels to small, complex brackets, connectors and contacts and produce them quickly and accurately. We also offer a full range of finishing options for your formed metal parts.

Precision CNC Machining

Our facilities do some of the most advanced, precise CNC machining work in the country, including tough materials like aluminum, titanium and Inconel. Do you have complex machining needs? We can handle them!

Metal Additive Manufacturing

Fathom has one of the largest fleets of Direct Metal Laser Sintering (DMLS) 3D printers in the U.S., with the expertise to match. This technology enables you to build complex geometries that aren’t possible using subtractive methods. Parts can also be post-machined and finished to meet specific application needs.

Photo Mechanical Etching

This manufacturing process is used to produce extremely flat, burr-free parts. It uses a chemical etching process similar to the ones used to produce computer chips. It’s used to produce small, precise components such as brackets, connectors and screens.

Expertise Building Parts for Tough Environments

From temperature extremes to corrosive environments, the parts we build are used in some of the most demanding applications. Our ISO 9001:2015 certification is your assurance that our parts are built to the highest level of quality.

Current ICT & Energy Projects

We have a solid track record of success building the types of components you need:

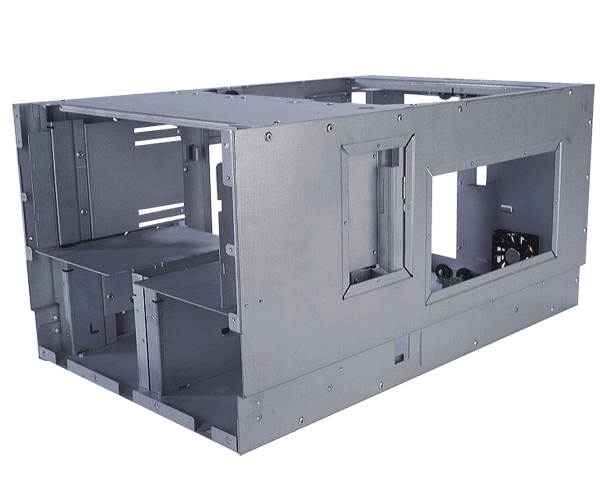

Server Racks & Enclosures

Majestic Metals by Fathom, our Denver location, has been building server and data storage racks for many years. We not only do the sheet metal fabrication, but also assembly and finishing. Our customers appreciate the excellent build quality and commitment to on-time delivery!

Components for Liquid-Based Cooling Systems

Centex by Fathom, our location in Austin, is working with several local startups that are designing liquid cooling systems for AI server racks. Our experienced team is helping them iterate their designs to deliver maximum cooling to densely-packed server racks, which generate massive amounts of heat.

ITC & Energy Application Expertise

We have years of experience delivering high-quality parts for data center, electrical power transmission and distribution and energy storage applications.

-

Server rack and enclosure systems

-

Manifolds, port blocks and brackets for server cooling systems

-

Pump, heat exchanger and cold-plate adjacent metalwork for cooling systems

-

Power distribution, busways and intelligent PDUs

-

Power module chassis and mounts

-

EV charging enclosures, pedestal bases and service panels

-

Switchgear and control cabinet enclosures

-

Busbar supports and structural frames

-

BESS enclosures for energy storage

-

Inverter and PCS cabinets

Why Choose Fathom for Critical ICT & Energy Projects?

We have immediate capacity and expertise to understand your projects and move them quickly into production. Our white glove approach means your part designs will get the attention and urgency they deserve, so you can keep your critical projects on time.

-

Short-Run, High-Mix Parts – Fast

We have the systems, processes and technical expertise to be able to deliver short-run, highly customized parts that meet your requirements and the agility to move and adapt quickly to your changing needs.

-

Focused on New Product Innovation

Rapid prototyping is one of our core competencies. We have decades of expertise helping our customers bring their product designs to market quickly and efficiently.

-

Accelerated Product Development

Fathom is uniquely organized to support a flexible development environment, ideal for the rapid iteration needed in these fast-moving industries. We can match your speed and agility, efficiently handling ECOs and program changes.

-

Our White Glove Approach

We’re problem solvers. Bring us your complex geometries, short-run/high-mix parts and “impossible” projects. Our expert engineers and production teams will help you get the work done, quickly and efficiently!

-

Quality Assurance

Our certifications are proof that the parts we build meet strict industry specifications and requirements. We’re also able to accommodate customer-specific quality requirements.

ISO 9001:2015

-

Streamlined Processes

You don’t have time to babysit a supplier. You need a partner that has a streamlined process to efficiently manage your projects from RFQ to finished parts – with a minimum of hassle. Our white glove approach provides proactive communication and a minimum of handoffs. No surprises. Just high-quality parts, surprisingly fast.

-

An Extended Network of Partners

In addition to our 7 U.S. locations, Fathom Edgeworks gives you access to a global network of manufacturing partners – combined with U.S.-based engineering and project management. No matter what your needs are, we offer the industry’s broadest range of manufacturing solutions.