Medical Device Manufacturing

Our Medical Customers

We Build Parts as if Lives Depend on It. Because They Do.

We know you’re under a lot of pressure today. You need to innovate and bring new products to market faster, while ensuring the highest quality and maintaining strict regulatory compliance. This balancing act is hard enough without having to worry about your contract manufacturer:

- You’re committed to innovation in medical device design – but your vendor is lagging behind.

- Your vendor seems to have forgotten the word “rapid” in rapid prototyping. Iteration cycles are taking too long.

- Delivery timelines are slipping. If they don’t solve their problems soon, your latest product launch will be in critical condition.

- Problems with part quality are getting worse. The thought of hospital system audit is giving you a migraine.

Across our network of U.S. locations, we have decades of medical manufacturing experience, backed by white glove, hands-on service. We’ve helped manufacturers like you engineer and produce everything from medical device enclosures and surgical tools to orthopedic implants and spinal screws.

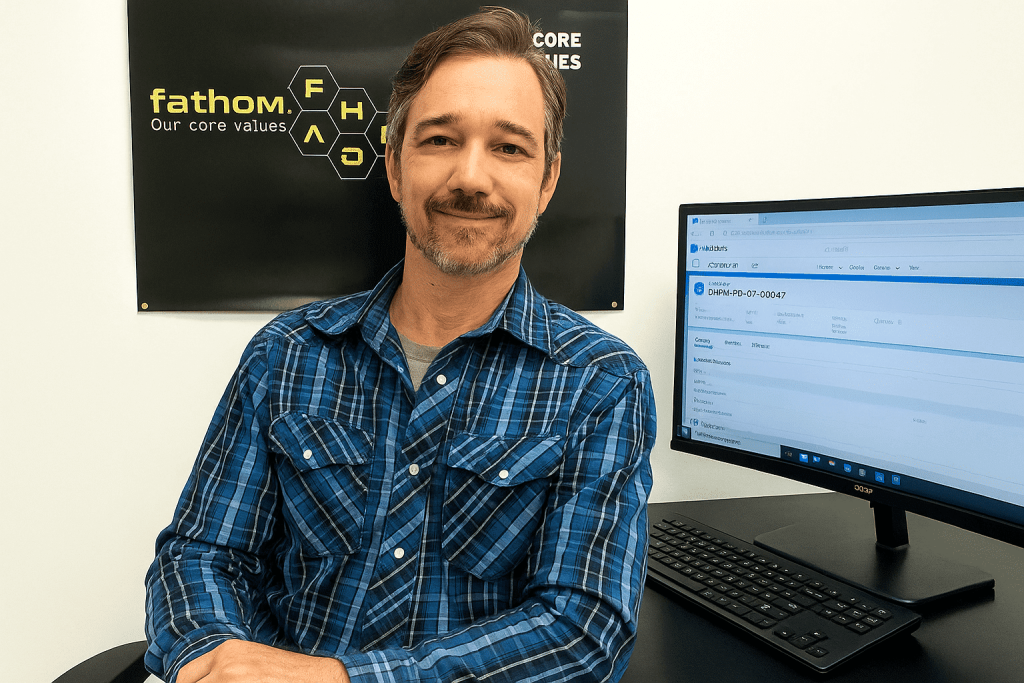

Human-First Manufacturing

With so much at stake, it’s comforting to know that you’ll have access to a team of experienced professionals. We’ll help you through every step of the product lifecycle, from part design and prototyping to scaling up production. It’s all part of our white glove approach to meeting your needs.

Account Manager

Applications Engineer

Project Coordinator

Customer Success Representative

Our Expertise – By the Numbers

3500+

25+

100+

ISO13485

How Do Medical Device OEMs Use Fathom?

Unmatched Breadth of Technologies

We offer more manufacturing technologies than any other contract manufacturer. Get more of your needs met with one supplier and one set of quality standards.

Rapid Prototyping

We’re set up to manage your rapid prototyping needs for your time-critical projects. Our expert engineers can help you quickly test, iterate and finalize your part designs for production.

Product Lifecycle Support

We can support your needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes as well as bridge production and full production. We specialize in low-volume/high-mix projects. Your new product is in good hands with us.

Engineering & Design Support

We take a hands-on, white glove approach to DFMs to ensure thatanypotential part design issues are identified and solved early in the design process. We can help you optimize your part designs, production processes and material selections for the best results, at the best price.

Quality Assurance

At Fathom, our commitment to in-house inspections enables us to turn around parts quickly, including CMM validation, surface inspections and tensile strength testing. In addition, we have a proven ability to comply with any medical OEM’s process, material and workmanship standards.

Comprehensive Capabilities for Medical Device Manufacturing

With a portfolio of 25+ advanced manufacturing technologies, we’re able to provide you with blended solutions that meet your exact requirements. It’s all backed by our white-glove, hands-on service. From the doctor’s office to the emergency room, we’ve got you covered.

Precision Machined Parts

We have decades of expertise machining tight-tolerance parts for critical medical components including implants (knee, hip, shoulder, toe, ankle, femoral and tibial), surgical instruments (drill guides, reamers, inserters, extractors, retractors, slap hammers, saw guides and broaches) and cutting tools.

Complex Metal Forming & Turning

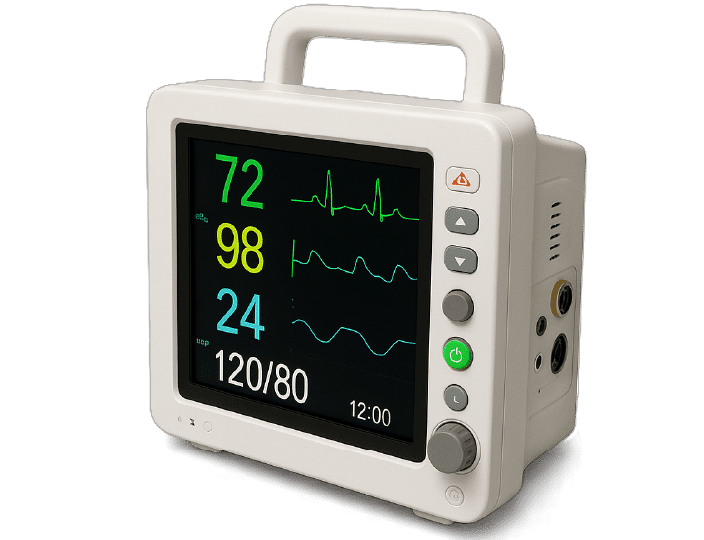

Our sheet metal experts can help you optimize your designs for production, from monitoring and diagnostic equipment to brackets, springs and connectors used in hospital and home care environments. Our machined parts are also widely used in CT scanners, X-ray and MRI machines.

Additive Expertise

We’ve been building parts using additive technologies for over 40 years. During that time, we’ve manufactured components for everything from medical imaging and orthopedics to patient monitoring, rehabilitation and in-home care. We’ve seen a lot and can help you avoid common design problems for your projects.

Materials Expertise

Today, medical devices are used far and wide, well beyond the doctor’s office or hospital environments. Mobile monitoring and in-home care devices must be designed for ruggedness and reliability. Leverage our process and materials expertise to help you select the right options for your unique needs.

Common Medical Applications

We have years of experience meeting the world’s most demanding medical device applications, including

-

Surgical instruments

-

Implants

-

Prosthetics

-

Medical device housings

-

Wearable monitoring devices

-

Medication delivery systems

-

Components for imaging equipment

-

Catheter system parts

-

IV connectors

Why Choose Fathom for Your Medical Device Parts?

No matter which segment of the medical industry you serve, we have the capacity and expertise to help you achieve your objectives.

-

Application Expertise

We understand the environments that your parts are exposed to, from in-body applications to the operating room. We’ll recommend materials, processes and finishing options to ensure your parts will meet your performance, cost and timing targets.

-

Your Lifecycle Partner

We can support your needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes to verify fit, finish and functionality to bridge and full production.

-

Unmatched Breadth of Manufacturing Technologies

We offer more advanced manufacturing technologies than any other contract manufacturer, plus a wide variety of in-house finishing services. This combination enables you to simplify your supply chain and your supplier base.

-

Track Record of Success

We have a long track record of success delivering high-quality parts to a variety of medical OEMs. From diagnostic and surgical tools to prosthetics and implants, we’re a trusted partner of manufacturing solutions to leading companies in your industry.

-

Relevant Certifications

Our certifications include:

- ISO 13485:2016

- ISO 9001:2015

In addition, we have a proven ability to comply with customer-specific process, material and workmanship standards.