Precision CNC Machining with Medical-Grade Accuracy

Our Customers

High Precision Machining Experts

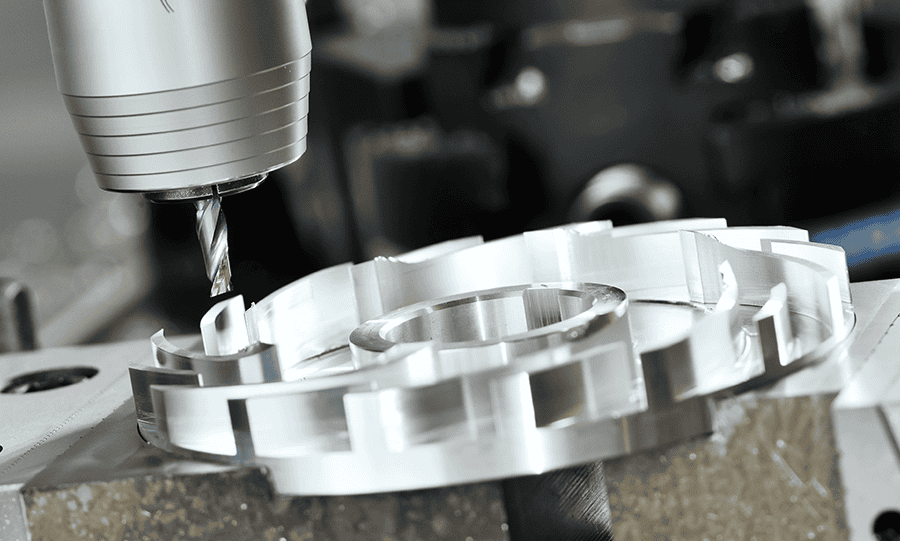

At Precision Process by Fathom, we specialize in doing close tolerance, high-precision machining of hard-to-machine materials. We can meet a wide range of requirements for unique geometries, including profiling, turning, grinding, 3D milling and 4-axis milling.

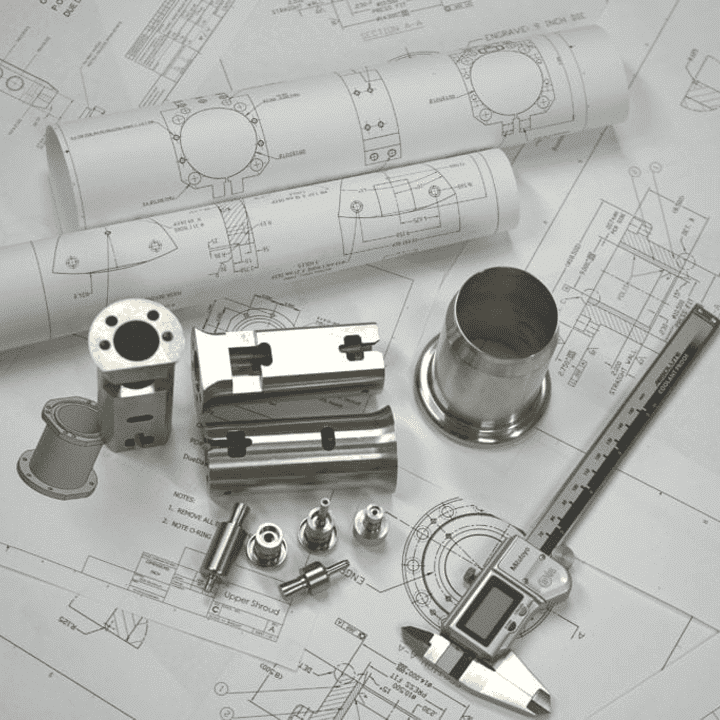

From complex, tight-tolerance parts made from the world’s toughest metals to rigorous processing, cleaning and inspection protocols for medical device components, our team has deep expertise in all aspects of high-precision manufacturing.

Services & Capabilities

At Precision Process by Fathom, we produce high-precision parts used in the medical industry, processed to strict customer standards.

High Precision Machining

We can meet a wide range of requirements for unique geometries, profiling, turning, grinding, and 3- and 4-axis milling with extremely tight tolerances.

Grinding

By combining CNC machining and high precision grinding in one room, we offer increased control, quality assurance and efficiency that result in lower production costs. Our equipment enables us to grind multiple diameters in one plunge and produce mirror-like surface finishes.

Wire and Sinker EDM

Wire EDM cutting is ideal for creating complex designs that may be challenging to fabricate using other cutting techniques or CNC machining. It can also cut sharp corners with minimal radii. Sinker EDM creates blind pockets in metal by “sinking” an electrode into the material. It’s used to create complex shapes, such as those needed for making molds, dies and other types of tooling.

Tough Metals are Our Specialty

We have extensive experience working with many types of metal, including exotic alloys:

-

Stainless steel

-

Tool steel

-

Inconel

-

Kovar

-

Titanium

-

Niobium

-

Molybdenum

-

TZM

-

Aluminum

-

CPM powder metal

-

Plastics

Customer Testimonials

High-Precision Machining for Your Toughest Applications

12+

12,000+

ISO 9001

100%

Industries Served

Precision Process by Fathom is a preferred provider to a range of industries that require tight-tolerance, complex parts produced at a high level of quality, including:

-

Medical

-

Semiconductor

-

Electronics

-

Packaging

-

Automotive

-

Metal stamping

Applications

We fabricate a wide variety of products for our discerning customers, including:

-

Medical devices (cathode and anode components)

-

Medical device screens

-

Dies

-

Punches

-

Forming parts

-

Feed fingers

-

Strippers

See What Precision Process by Fathom Can Build For You

Download our linecard for an overview of our precision CNC capabilities and the engineering expertise that sets our team apart.

Service Area

While we partner with companies nationwide, our Elk Grove location proudly supports many customers throughout the region, including:

Illinois // Chicago | Aurora | Naperville | Joliet | Rockford | Springfield | Elgin | Peoria | Champaign

Indiana // Gary | South Bend | Fort Wayne | Indianapolis

Wisconsin // Madison | Milwaukee | Racine | Kenosha

Iowa // Davenport | Iowa City | Cedar Rapids

Why Choose Precision Process for Your CNC Machining Needs?

-

Engineering Support

At Precision Process by Fathom, we provide engineering support every step of the way. From design concept validation and prototyping to production release, our experienced engineers will work with you to optimize your designs for manufacturability and cost-effectiveness.

-

Quality Control

We provide 100% quality control on all products and strictly adhere to quality assurance procedures. We maintain an ISO 9001:2015 certification. Our metrology lab is equipped with three state-of-the-art CMM machines, visual inspection system, optical comparators and other standard measurement equipment.