Small, Precision Formed Metal Parts. Big Speed.

Trusted by Industry Leaders

Rapid Prototyping of Small, Complex Parts is Our Specialty

Incodema by Fathom is a rapid prototyping precision sheet metal fabricating company specializing in small, complex parts. We can support your project from prototyping, production and post-processing under one roof. Because we are a vertically integrated company, you get a single point of accountability throughout the lifespan of your project.

25 years ago, we were one of the pioneers to offer rapid prototyping sheet metal services – parts in only 5-7 business days, not 6-8 weeks. Today, our can-do, customer-focused team continues to help our customers value-engineer their parts and deliver cost-effective solutions to their most challenging small metal parts manufacturing needs. They love the sense of urgency we bring to their projects!

Services & Capabilities

Incodema by Fathom offers an integrated solution to your small, complex metal part needs. From design input and manufacturability analysis to sophisticated post-processing.

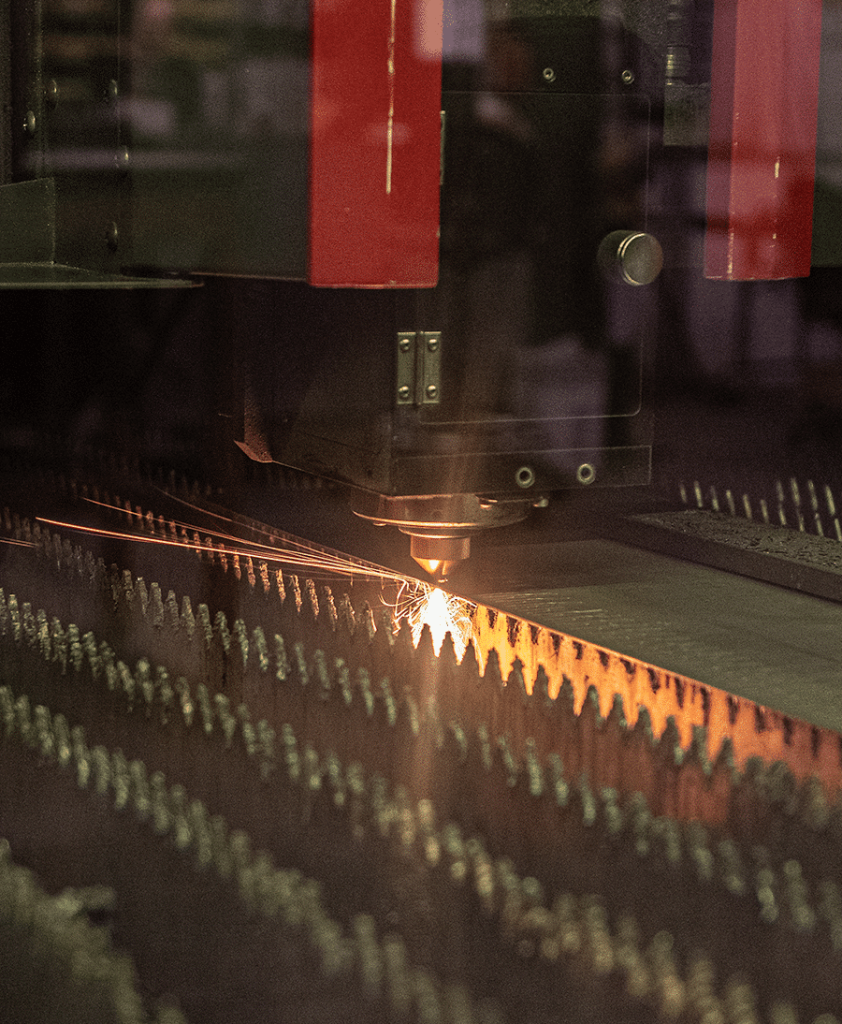

Sheet Metal Cutting

Laser Cutting // Laser cutting is highly accurate and yields excellent cut quality with minimal heat-affected zones. This process is ideal for fast, high-quality sheet metal prototype fabrication projects as well as low-volume production quantities.

Water Jet Cutting // This tool uses a high-pressure stream of water to cut a wide variety of materials with superior edge quality and minimal burr. It is ideal for heavy gauge and tough metals and can cut materials with a thickness of up to 6 inches.

MicroCut™ // This is a specialized water jet cutting tool that uses an even finer stream of water to make cuts with tolerances rivaling wire EDM.

Photochemical Machining // This is a process of selectively removing material by using a chemical action, and it is the ideal manufacturing solution for flat parts with complex geometries such as encoders, screens and filters.

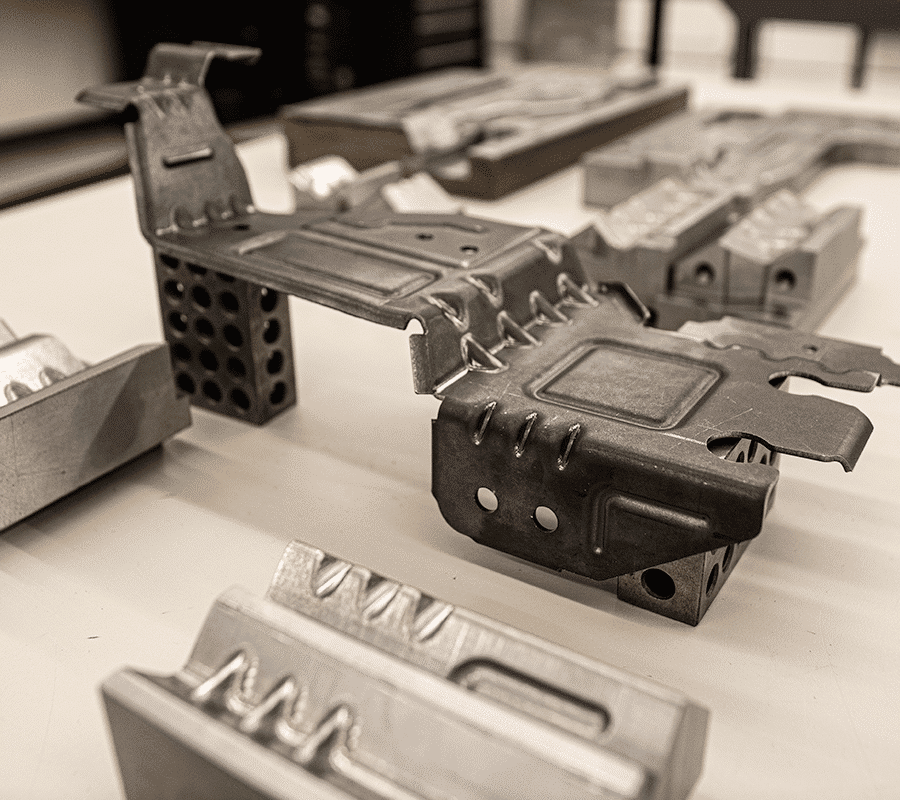

Sheet Metal Forming

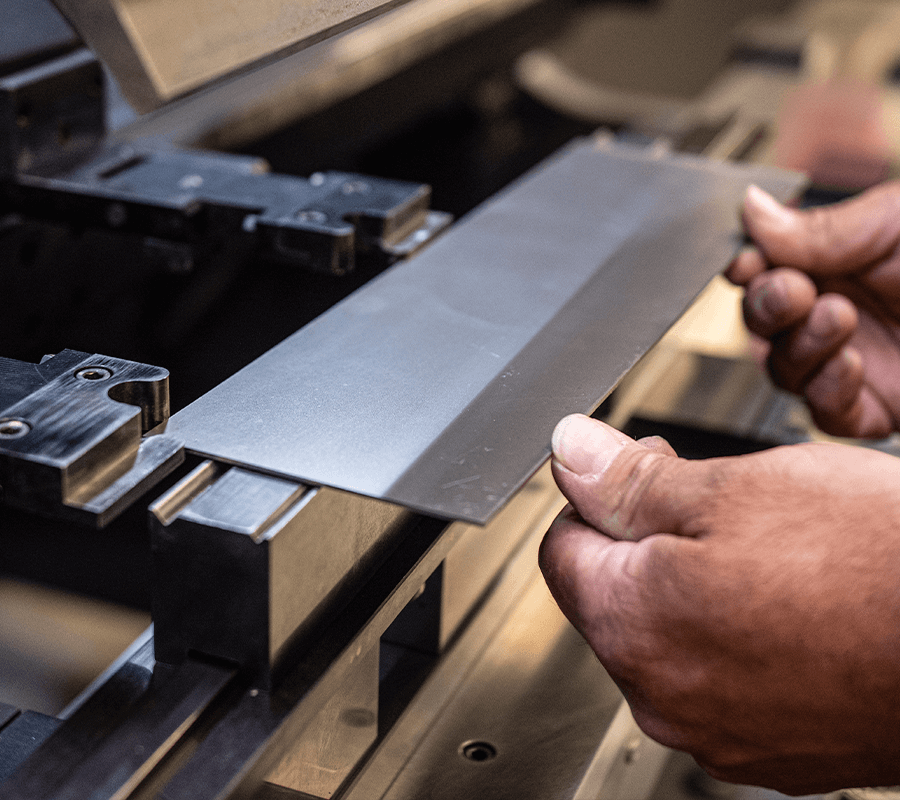

Manual Progressive Dies // We have developed a technique in which we turn an ordinary press brake into a manual progressive die by adding multiple die sets to a single brake. This process is so precise that we refer to it as “sheet metal origami” on the shop floor.

Manual Forming: Large Format // While small, complex parts are our specialty, we also offer large format services in-house. We maintain a 300-ton press with a 36″ x 72″ bed in our facility to form parts that are too large for a traditional press brake.

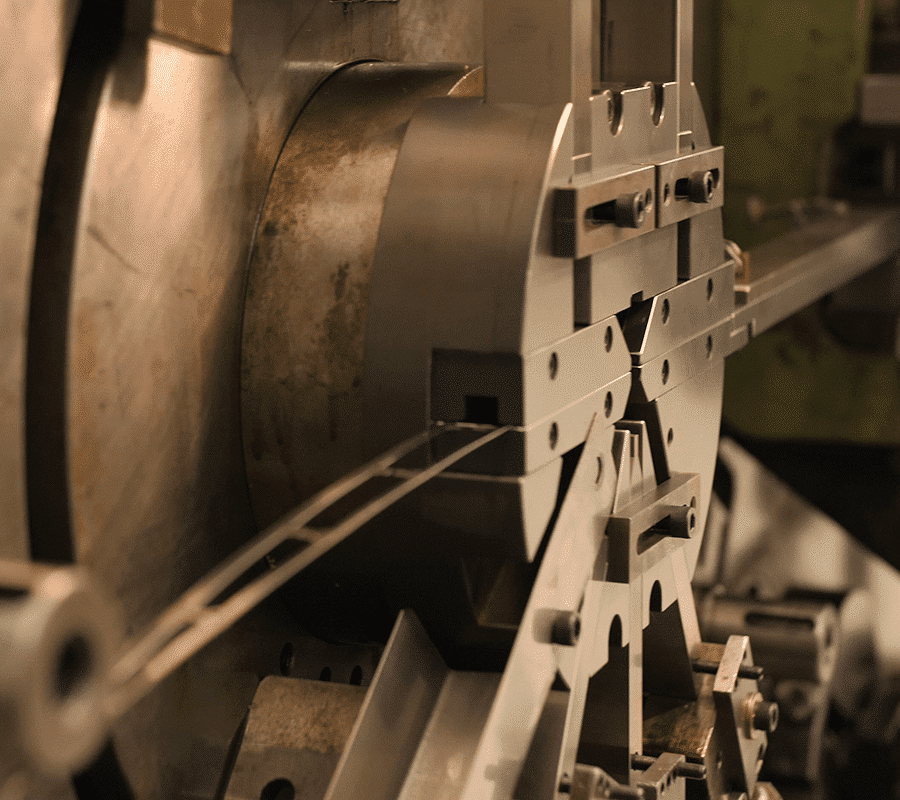

Mid to High Volume Sheet Metal

Semi-Automated Manufacturing // We offer a variety of cost-effective, semi-automated tooling solutions that cost 15-30% of the cost of fully automated production tooling.

Put-and-Take Tooling // Semi-complex dies, actuated manually or by machine, form complex features and/or multiple bending operations in one step.

Die Blanking // Flat parts and some parts with formed features may be manufactured completely in full automation or made ready for secondary, semi-automated bending and forming processes.

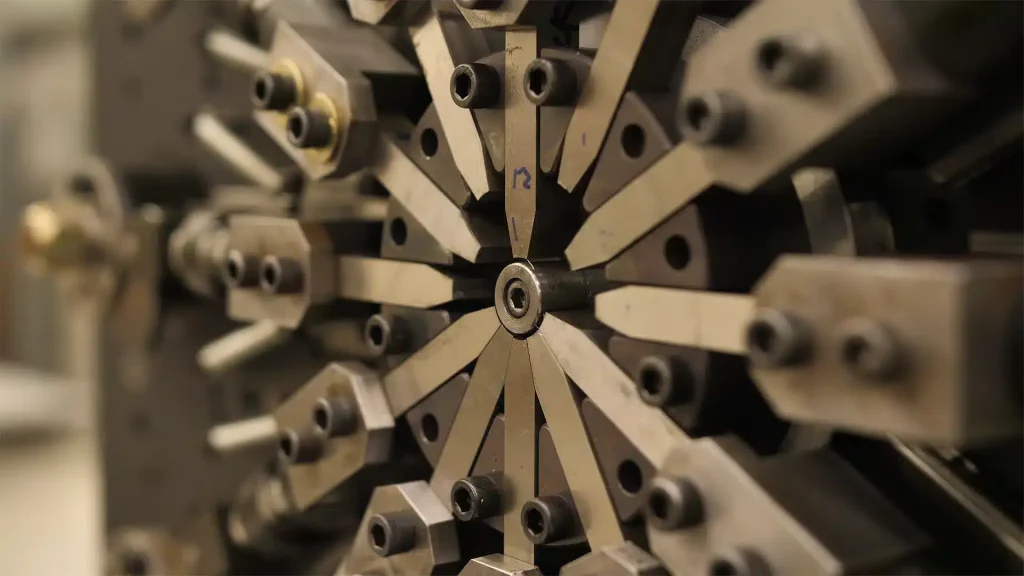

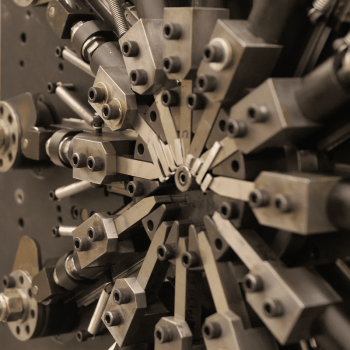

Four-Slide and Multi-Slide Stamping // Four-slide and multi-slide manufacturing are ideal for small and intricate parts. They use custom tooling to quickly make multiple precise bends in a flat blank in seconds.

Specialty Stamping // Our skilled and creative toolmakers can design and create complex tooling solutions necessary to manufacture even the most challenging stamped parts. Many of Incodema by Fathom’s operators have engineering skills, and they are empowered to develop manufacturing solutions on the fly to keep the manufacturing process moving quickly and smoothly.

Post Processing

Welding // Our in-house welding experts can join your parts using arc, MIG, TIG, laser, resistance spot or oxyfuel welding.

Outside Processing // We maintain strategic partnerships with key suppliers of heat treating, plating and powder coating who understand our need for quality and speed. All our processes are NADCAP certified and RoHS compliant.

Post-Machining // Our in-house CNC machining centers allow us to post-mill features into your sheet metal components to meet your requirements while maintaining our fast turnaround times.

In-House Custom Tooling // If you have special requirements, our team of engineers and master tool makers can develop creative tooling solutions for your formed parts. Complex bending and precision forming are our specialties.

Deburring and Finishing // We can uniformly remove laser dross, mechanical burrs or sharps and other surface imperfections with our in-house deburring and finishing operations. Our processes range from hand sanding to automated deburring, tumbling and finishing.

Complex Sheet Metal Parts – Fast!

5-7

4 Hours

ISO 9001

ITAR

Industries We Serve

-

Electronics

-

Defense

-

Aerospace

-

Life sciences

-

Industrial

Applications

A wide variety of industries use precision sheet metal manufacturing to produce their prototypes and final products. It can be used for:

-

Medical products

-

Office equipment

-

Communications products

-

Housing

-

Chassis

-

Enclosures

-

Brackets

-

Appliances

See What Incodema by Fathom Can Build For You

Download our linecard for an overview of our sheet metal fabrication capabilities and the engineering expertise that sets our team apart.

Service Area

While we partner with companies nationwide, our Ithaca location proudly supports many customers throughout the region, including:

New York // Buffalo | Rochester | Utica | Mount Vernon | Syracuse | Binghamton | Elmira | Niagara Falls | Albany | Schenectady | Cornwall | Poughkeepsie | Yonkers

Pennsylvania // Erie | Scranton | Wilkes-Barre | Philadelphia

New Jersey // Newark | Jersey City | Camden

Why Choose Incodema by Fathom?

At Incodema by Fathom, we can help you solve your biggest precision sheet metal design challenges. Our team of engineers and master tool makers can develop creative tooling solutions to form your parts.

Why should you invest in sheet metal prototype fabrication? It enables you to test it for form, fit and functionality. It can also help eliminate the guesswork in manufacturing and reduce your overall costs.

Our unique in-house blend of metal-cutting and forming technologies, combined with experienced engineering and production teams and can-do culture, enable us to help you quickly finalize your part designs and bring your new products to market faster.