The Midwest’s Complete Manufacturing Partner.

Our Customers

From Prototype To Production, Fathom Has You Covered

Fathom’s Hartland, Wisconsin headquarters is a high-precision, responsive, comprehensive manufacturing hub supporting your product at any stage of its lifecycle — from prototyping and design for manufacturability to full-scale production, post-processing and supply chain optimization.

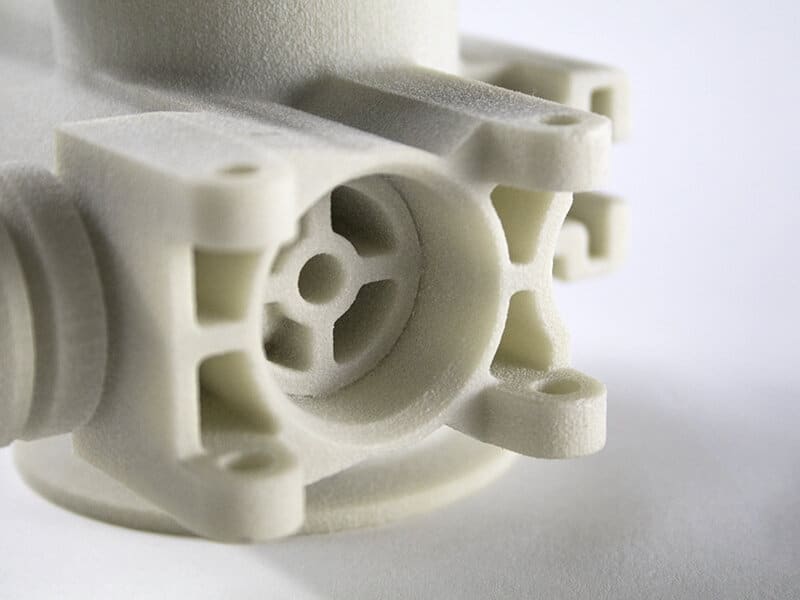

Additive Manufacturing

We can guide you to achieve the full potential of additive manufacturing – from early concepts and rapid prototyping to production and finishing. Our experienced engineering team can help you select the right technology, material and process that meets your needs. We offer a comprehensive selection of finishing options under one roof. We can deliver 3D-printed parts as fast as the next day.

CNC Machining

CNC machining is perfect for a wide range of applications. For customers in demanding industries like defense, aerospace, medical and automotive, it meets their need for precision, repeatability and accuracy. For others, it provides a cost-effective way to get the parts they need at a reasonable cost.

FRP Fiber Layup

We offer advanced FRP fiber layup capabilities for producing lightweight, high-strength composite components with precision and repeatability. Ideal for applications that demand durability without excess weight, our fiber layup process allows us to create complex, performance-driven parts while maintaining strict quality standards.

Post-Processing & Finishing

Fathom Manufacturing offers assembly and finishing services that further enhance the look of your design, helping you achieve specific textures and colors. Our professional finishing services are often used for marketing photo shoots, tradeshows, internal presentations and more.

Customer Testimonials

Quality, Service & Speed – For All Your Manufacturing Needs

40+

ISO 9001

ISO 9100

ITAR

Industries Served

Thanks to our breadth of services, our Hartland, WI facility serves numerous industries. We help our customers accelerate their product lifecycles with white-glove support – everything from design and engineering assistance and prototyping to bridge and full production.

We work with leading manufacturers in these industries:

-

Aerospace and defense

-

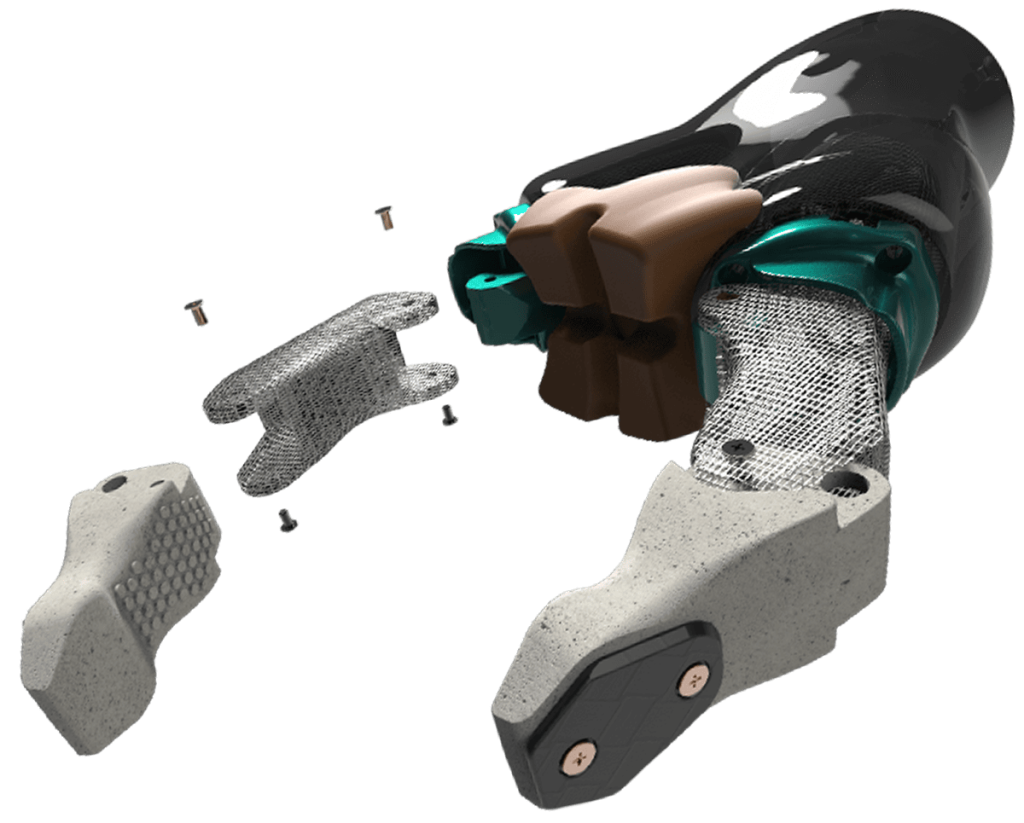

Robotics

-

Automotive & EV

Applications

We fabricate a wide variety of products for our discerning customers, including:

-

Components for military and defense applications (including black ops projects)

-

Aircraft and drone parts

-

Robotic components

-

Electric vehicle interior and exterior parts

-

Prototype body panels for off-highway equipment

Service Area

While we partner with companies nationwide, our Hartland location also proudly supports many customers throughout the region, including:

Milwaukee | Madison | Waukesha | Racine | Kenosha | Brookfield | Green Bay | Oshkosh | Chicago | Rockford | Aurora | Elgin

Why Our Customers Choose Fathom’s Hartland, WI Facility

We specialize in low-volume, high-mix projects and support you throughout your product lifecycle, from design to production. Utilizing a white-glove approach, we’ll work closely with you to understand your requirements and the application where you parts will live. We’ll then recommend a manufacturing technology, material and finishing options that will meet your cost, timing and quality needs.

-

Deep Engineering Expertise

Our process starts with a detailed DFM report. But it doesn’t end there. Our engineers have decades of expertise, which enables them to uncover geometry-specific “gotchas” and solve them before your parts go into production. Our experienced engineers will work with you to optimize your designs for manufacturability and cost-effectiveness.

-

Integrated Services

Our Hartland facility is fully equipped to meet all of your post-processing needs. That enables us to handle key finishing steps for you, in-house. This approach saves you time and money and enables us to provide you with value-added parts that exactly fit your needs.

-

Deep Capacity

We operate 7 types of 3D printing machines and multiple 3-, 4- and 5-axis CNC machine tools plus wire EDM cutting – over 120 machines in all. We’re ready and able to meet your needs, whether you’re developing a new prototype component or moving a key product into production.

-

Global Reach

Hartland is the home of Fathom Edgeworks, our global sourcing solution. It’s a fully managed, expert-led program designed to give you the lowest fully landed cost, backed by U.S.-based support. No matter what your contract manufacturing needs, we offer a full range of domestic and overseas solutions to meet your needs.