Our Customers

Flat Metal Parts Faster Than You Ever Thought Possible.

Photochemical machining from Newcut by Fathom can revolutionize how you design, develop and produce complex, flat metal parts. For over 50 years, we’ve been a leader in this unique technology, with a reputation for exceptional quality, accuracy and service.

Photochemical machining enables you to accelerate your prototyping process and get your parts into production faster. It doesn’t require hard tooling, which means we can deliver your parts in a matter of days, not weeks or months. Design changes are also much easier to accommodate with chemical etching than with other manufacturing methods.

Photochemical Machining Services & Capabilities

Newcut by Fathom provides short lead times, cutting-edge equipment and the ability to etch flat metal parts for customers across the country.

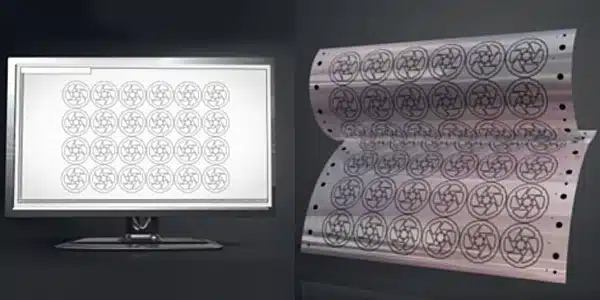

Film Production

The first step in the photochemical machining process is to produce films based on your part designs. These can be made in a matter of hours, much faster than tooling or workholding fixtures required for other manufacturing processes.

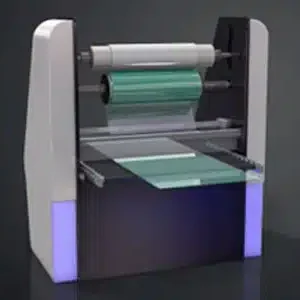

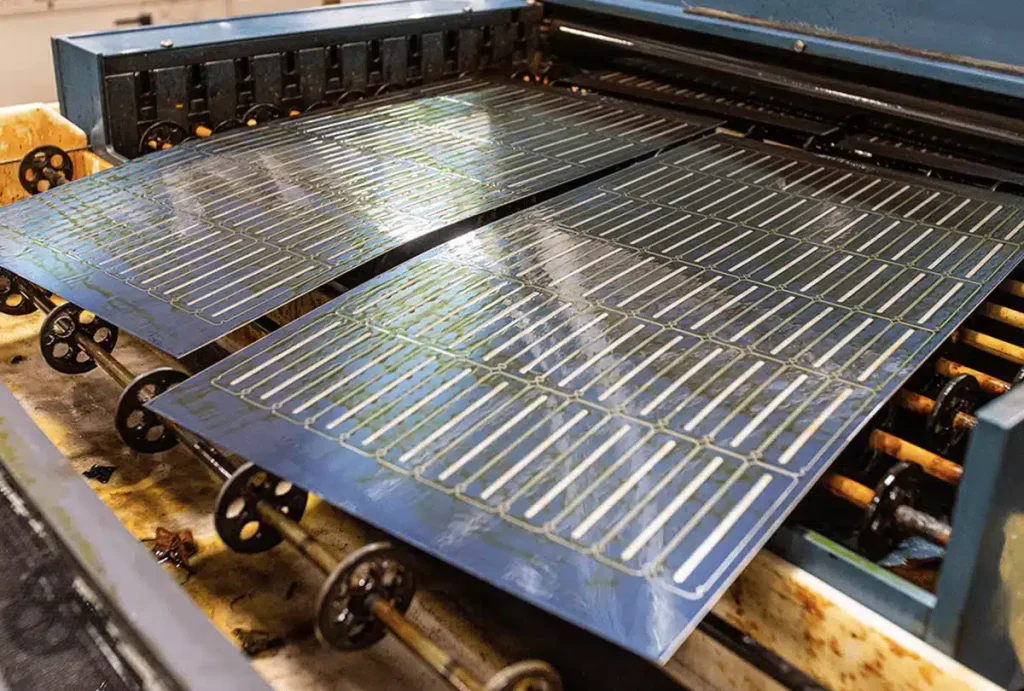

Photochemical Machining

Photochemical machining works by “printing” a part design onto photoresist which is transferred onto a thin sheet of metal. The areas of photoresist that have not been printed are washed away with a developing solution, leaving a precisely masked piece of metal. The masked metal is sprayed with an acidic etching solution, leaving a precise, burr-free part.

Post Processing & Finishing

No Burrs = Less Post-Production // Burrs are a common side effect of many types of metal processing. In contrast, the chemical etching process produces a clean, smooth surface. It’s free of burrs and eliminates the need for manual finishing processes.

Plating // Finished blanks may be outsourced to a local supplier for plating. In most cases, the parts are ready to ship after the etching process is complete.

Heat Treatment // This process may be used to enhance the physical characteristics of the metal.

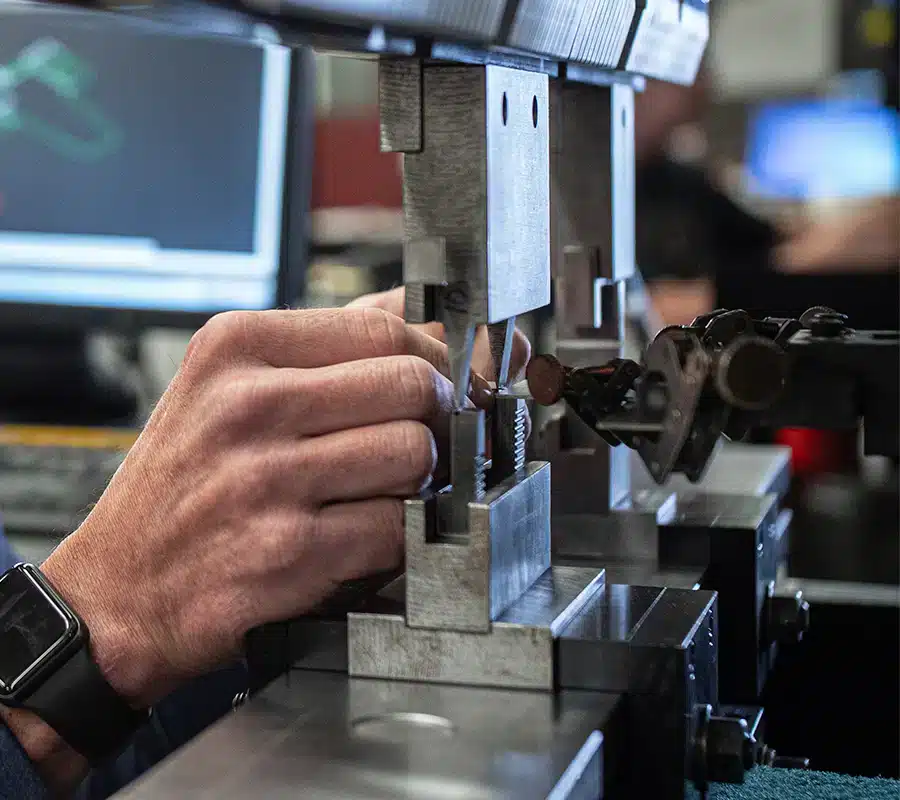

Precision Forming // Fathom has a close relationship with the nearby Incodema by Fathom facility, which uses precision forming tools to turn the blanks into complex formed parts.

Photochemical Machining From Fathom – At a Glance

ISO 9001

ITAR

AS 9100

0.001″

Industries Served

-

Aerospace

-

Architectural

-

Automotive

-

Commercial

-

Decorative

-

Electronic

-

Medical

-

Military

-

Optics

-

Energy

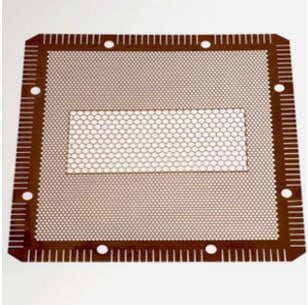

Applications of Photochemical Etched Parts

-

Connectors

-

Electrical contacts

-

Encoders

-

EMI or RF shielding

-

Filters and screens

-

Flat springs

-

Signage

-

Washers and shims

-

Diffusion bonding

See What Newcut by Fathom Can Build For You

Download our linecard for an overview of our advanced photochemical etching capabilities and the engineering expertise that sets our team apart.

Service Area

While we partner with companies nationwide, our Newark location proudly supports many customers throughout the region, including:

Ithaca | New York | Buffalo | Rochester | Utica | Mount Vernon | Syracuse | Binghamton | Elmira | Niagara Falls | Albany | Schenectady | Cornwall | Poughkeepsie | Yonkers

Why Choose Newcut by Fathom for Your Photochemical Machining Needs?

Newcut was one of the early innovators of photo chemical etching and has been producing flat precision parts for a wealth of customers, industries and applications for over 50 years. During that time, we’ve built a reputation for exceptional quality, accuracy and service.

Newcut provides short lead times, cutting-edge equipment and the ability to etch specialty metals for customers across the country.