Most companies are under pressure to accelerate their new product development programs. It’s incredibly risky to move a part design directly into production. It may not fit into an assembly correctly. The finish may be flawed. The aesthetics may not be what you expected.

Many types of manufacturing require the construction of costly tools, which take several months to build. Making changes to tooling because of unexpected design problems can be very expensive and can derail your new product launch.

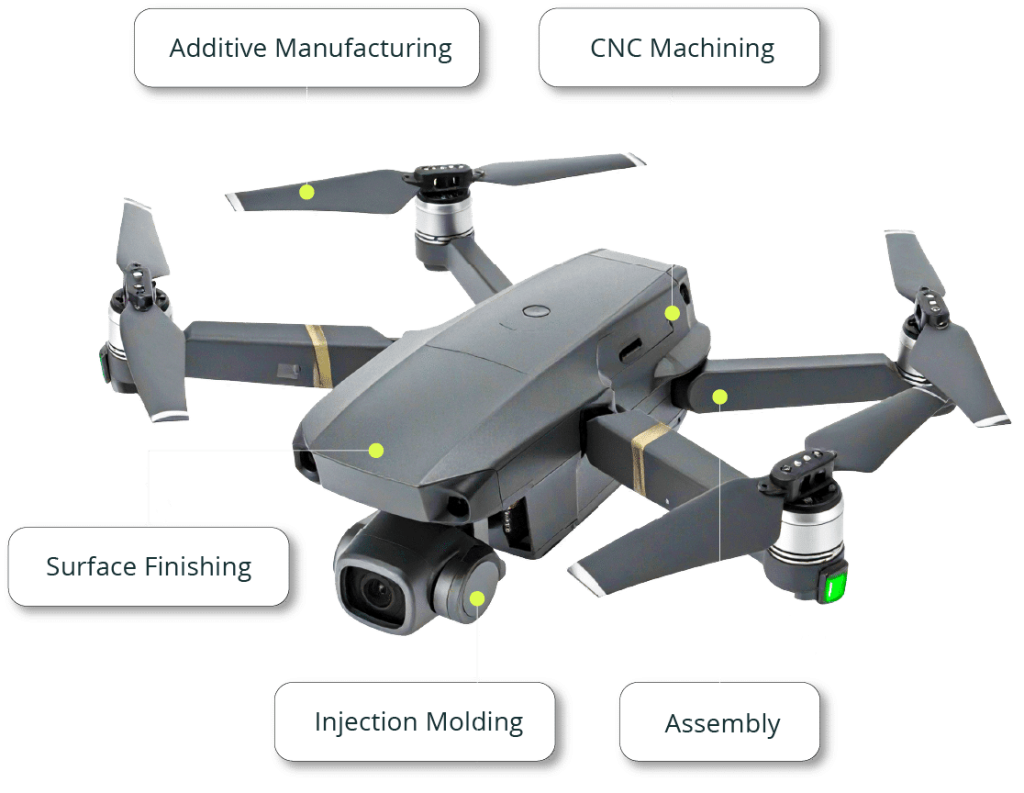

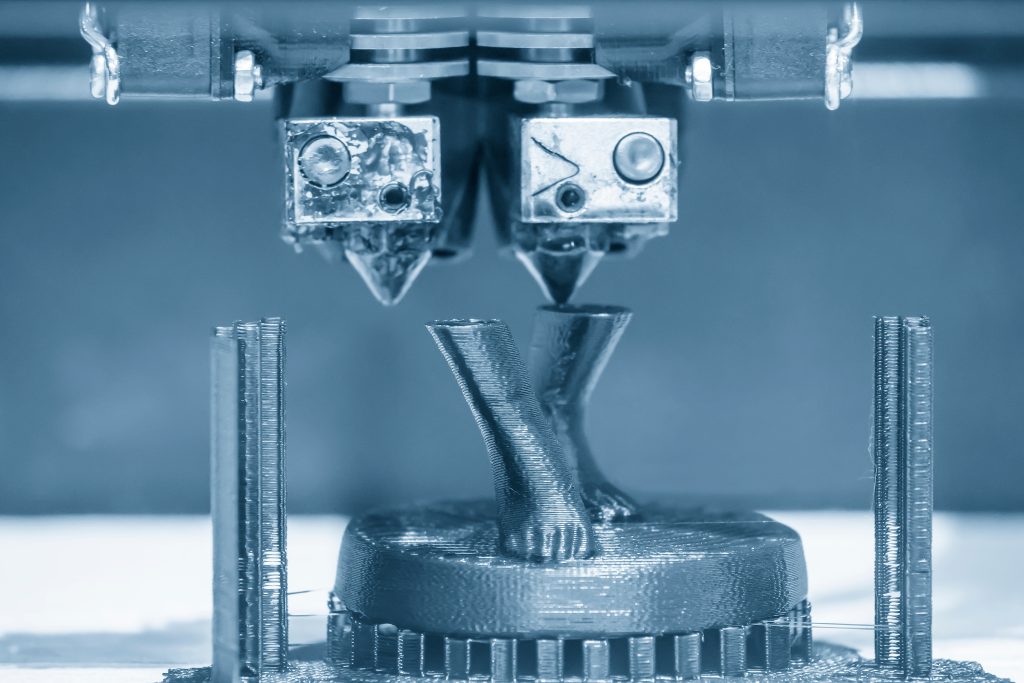

The solution? Refine, optimize and finalize your part design using an iterative process called prototyping, empowered by digital manufacturing methods. Prototypes not only provide product development, marketing and sales teams with a 3D model to validate their design concepts. They also help these teams verify fit, finish and performance before moving finalized part designs into production.