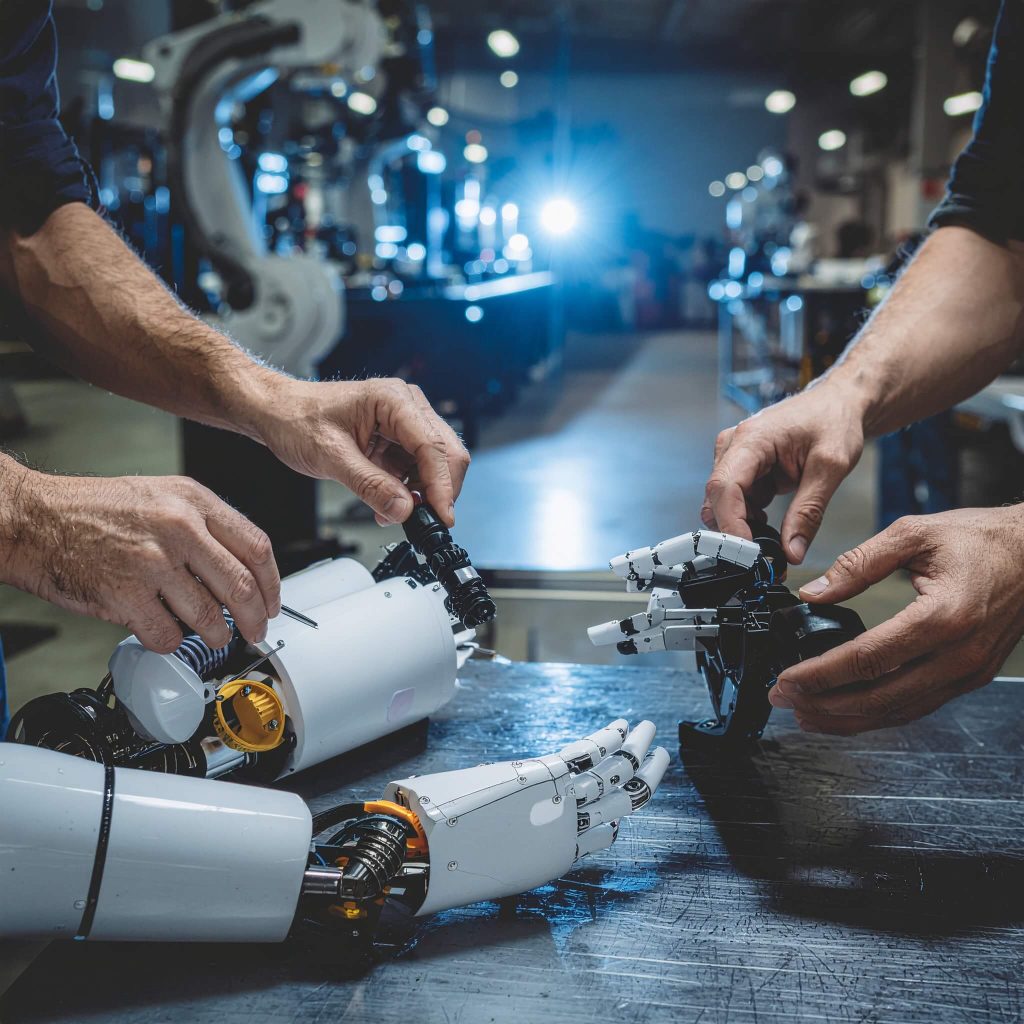

Robotics Manufacturing

Our Robotics Customers

Accelerate Your Robotic Programs – With a Trusted Partner

Are you struggling to manage quality across a fragmented supplier network? Component failures can bring your entire production line to a standstill and can cripple your new product development programs.

Your customers demand exceptional precision and reliability from your robots. You need a manufacturing partner that can maintain the same high standards while providing white glove service that’s tailored to your needs.

Fathom provides engineering and production expertise and produces high-performance, customized parts for every sector of the robotics and automation market, including:

- Assembly stations

- Cobots

- Pick-and-place applications

- Automated guided vehicles

- Loading and unloading of delivery vehicles

- Humanoid robots

- End-of-arm tooling

Human-First Manufacturing

From the moment you kick off your project, you’ll have access to a team of experienced professionals who will help you through every step of the process, from part design and prototyping to accelerating production. It’s all part of our white glove approach to meeting your needs and helping ensure the success of your production and new product development programs.

Account Manager

Applications Engineer

Project Coordinator

Customer Success Representative

Our Expertise – By the Numbers

3,300+

15

25+

ISO 9001

How Do Robotic & Automation Manufacturers Use Fathom?

Unmatched Breadth of Technologies

We offer more advanced manufacturing technologies than any other contract manufacturer. That enables you to get more of their needs met with one supplier.

Rapid Prototyping

We’re optimized to manage the rapid prototyping needs of our customers. Our expert engineers will help you quickly test, iterate and finalize your part designs for production.

Product Lifecycle Support

We’ll support your needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes as well as bridge production and full production. We specialize in low-volume/high-mix projects – ideal for new platform launches.

Engineering & Design Support

We take a hands-on, white glove approach to DFMs. That helps ensure that all of your potential part design issues are identified and solved early in the process. We’ll help you optimize your part designs, production processes and material selections for the best results, at the best price.

Quality Assurance

At Fathom, our commitment to in-house inspections enables us to turn around parts quickly, including CMM validation, surface inspections and tensile strength testing. In addition, we have a proven ability to comply with our customers’ specific process, material and workmanship standards.

Comprehensive Capabilities for the Robotics & Automation Industries

With a portfolio of 25+ advanced manufacturing technologies, we’re able to provide you with blended solutions that meet your exact requirements. It’s all backed by our white-glove, hands-on service.

Unmatched Additive Expertise

Additive metal technology, such as Direct Metal Laser Sintering (DMLS), is an ideal fit for the rugged yet lightweight needs of the robotics industry. Fathom can also produce parts using additive technologies like FDM, SLS, MJF and STEP.

Urethane Casting

Urethane Casting can be used to produce soft surfaces for end-of-arm tooling that simulate overmolding – without the complex, expensive tooling it requires. Urethane casting can be used to produce prototype parts quickly.

Sheet Metal Fabrication

Fathom can handle your large sheet metal needs as well as the precision forming of small, complex metal components. We also offer photo chemical etching, a process used to produce extremely flat, burr-free parts.

CNC Machining

Our facilities do some of the most advanced, precise CNC machining work in the country, including tough materials like aluminum, titanium and Inconel. Complex machining needs? We can handle it!

Common Robotics Applications

We have years of experience delivering high-quality parts for numerous types of robots and automated systems.

-

Robot frames and support structures

-

End-of-arm tooling

-

Jigs and fixtures for machining and assembly

-

Harnesses

-

Wire guides

-

Brackets

-

Pneumatic systems for picking and moving packages

Why Choose Fathom for Your Robot & Automation Projects?

By partnering with Fathom, you can concentrate on robot design and final assembly while offloading complex manufacturing work to a trusted, specialized partner.

-

Short-Run, High-Mix Parts – Fast

We have the systems, processes and technical expertise to be able to deliver short-run, highly customized parts that meet your requirements.

-

Focused on New Product Innovation

Rapid prototyping is one of our core competencies. We have decades of expertise helping our customers bring their robot and automation system designs to market quickly and efficiently.

-

Accelerated Product Development

Fathom is uniquely organized to support a flexible development environment, ideal for the rapid iteration needed in the hyper-competitive robotics market. We can match your speed and agility.

-

Robotics Industry Expertise

We have a long track record of success delivering high-quality parts to a variety of robotics companies, military agencies and other organizations that serve this fast-moving, cutting-edge industry.

-

Our White Glove Approach

We’re problem solvers. Bring us your complex geometries, short-run/high-mix parts and “impossible” projects. We’ll help you get the work done!

-

Certifications

Our certifications include:

- ISO 9001:2015

- ISO 13485:2015

- AS9100 Rev. D

- NIST 800-171

- ITAR

In addition, we have a proven ability to comply with customer-specific process, material and workmanship standards.