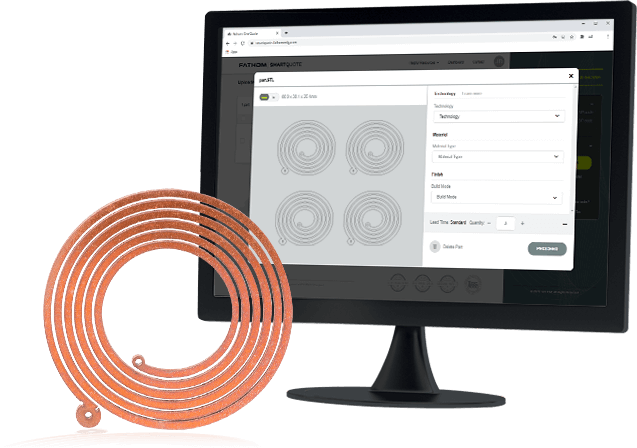

Water Jet Cutting

-

Ideal for Intricate Designs

-

High Cutting Accuracy & Tight Tolerances

-

No Heat-Affected Zones

Trusted by Industry Leaders

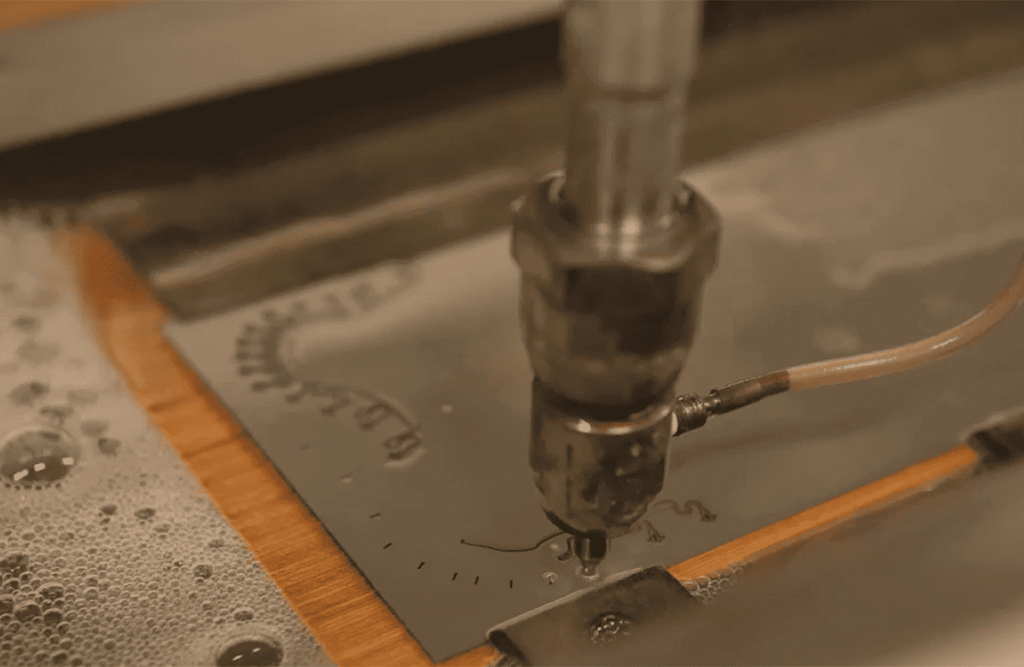

How Water Jet Cutting Works

Water jet cutting uses an ultra-high pressure stream of water to erode a thin line of material. It’s very precise and provides excellent edge quality with no heat-affected zones. It can even cut multiple sheets of metal at the same time. That helps make water jet cutting an affordable process. An abrasive substance may be mixed with the water, making it easier to cut hard or thick metals.

Sheet metal is first placed on a cutting table. It may be secured to prevent it from moving. The cutting table is designed so excess water and metal particles drain away. That keeps the cutting area clean. High-pressure pumps increase water pressure to extremely high levels. They force a stream of water through a nozzle. It accelerates the water to supersonic speeds. This tiny but powerful stream cuts a thin line through the material.

Water jet cutting makes clean cuts, which means that parts don’t require as much post-processing as with other cutting methods. Most significantly, it’s a cold process. It doesn’t cause heat-affected zones. In other words, the heat generated by cutting can alter the microstructure of the metal along the cutting edge. That can cause brittleness and other problems.

How Does Water Jet Cutting Compare to Other Cutting Methods?

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | ||

|---|---|---|---|---|---|---|---|---|

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° | |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. | |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast | |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon | |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

Advantages of Water Jet Cutting

Advantages

-

Material Versatility

Water jetting cuts virtually any material: From metal and stone to composites and even food, water jet cutting is extremely versatile. It can also cut bonded and laminated materials.

-

Complex Shapes & 3D Cutting

This technology can handle intricate designs and, with 5-axis cutting heads, can produce beveled edges and 3D shapes.

-

No Heat-Affected Zones

Water jet cutting doesn’t generate heat, which prevents damage from warping, distorting or hardening the material’s edge.

-

Can Cut Thick Materials

Water jets can cut through very thick materials, sometimes exceeding 10 inches, while maintaining accuracy.

-

Cost-Effective

Water jet cutting is efficient because of its fast setup and programming and by nesting parts closer together, it minimizes material waste

Disadvantages

-

Reduced Accuracy with Thick Materials

As material thickness increases, the cutting jet stream can spread and become less accurate, causing a diagonal cut rather than a straight one.

-

Slower Cutting Speed

Compared to other cutting methods, water jet cutting is often slower, which reduces output.

-

Inner Corner Radius Can’t be Eliminated

Water jets cannot create perfectly sharp inside corners and will leave a small radius equal to the width of the jet stream.

Applications That Can Benefit From Water Jet Cutting

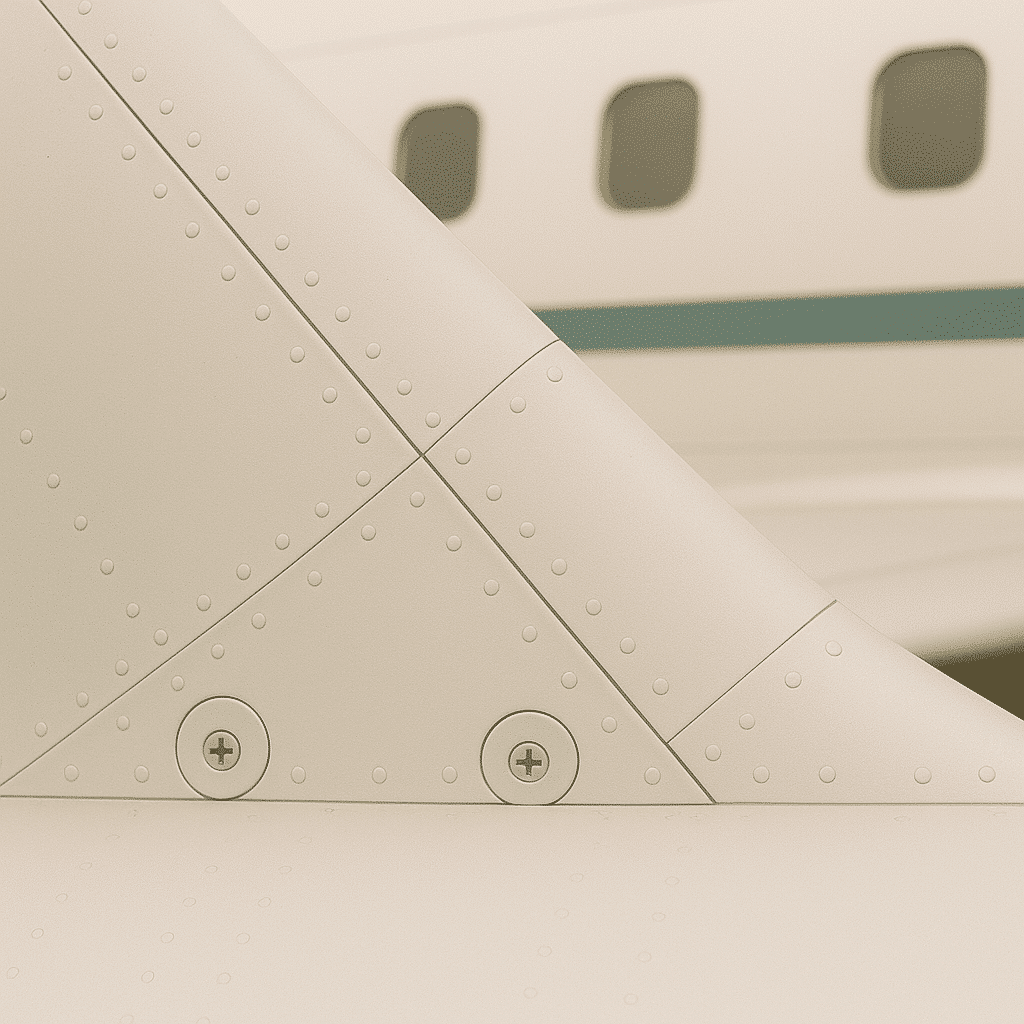

Aerospace

Water jet cutting is ideal for cutting tough metals, such as titanium and aluminum. They are widely used for aerospace and defense applications because of their combination of high strength and light weight.

Medical

Medical components need to be strong and light. That’s why water jet cutting is a preferred technology for creating components for medical device, prosthetics and surgical instruments.

Electronics

Water jet cutting is ideal for cutting high-precision components for electronic devices.

Automotive

Water jet cutting is favored for cutting dashboard, door panel and custom components for today’s automobiles.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.

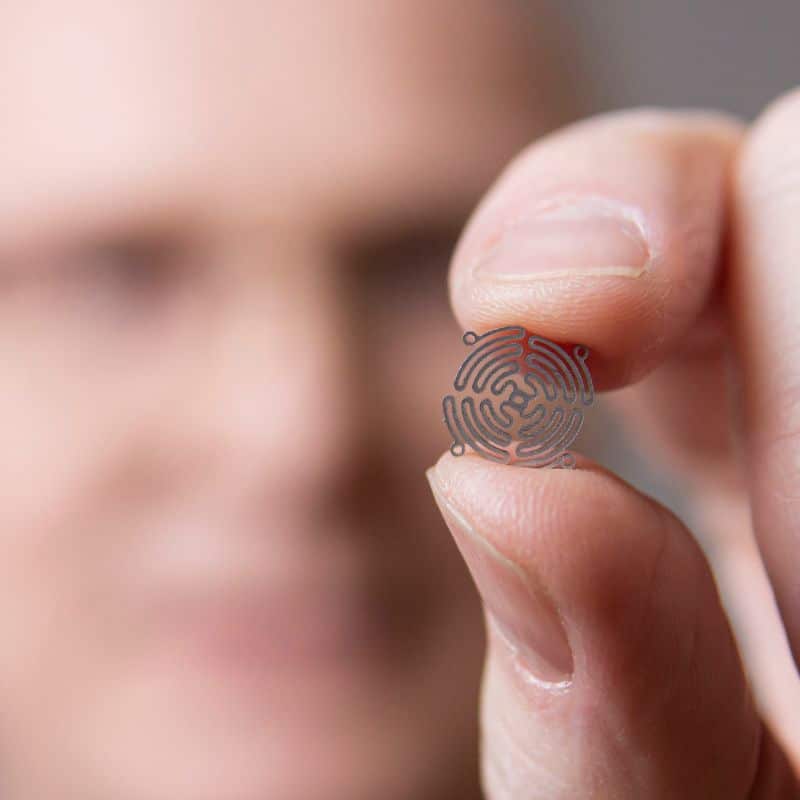

What is Micro Water Jet Cutting?

When you need exceptional precision for your highest tolerance metal parts, micro water jet cutting can help you achieve the results you seek. Fathom’s micro water jet machines can cut materials up to 0.5 inches thick with a tolerance of 0.0005″- 0.005″. It’s faster than cutting fine features with EDM and doesn’t create heat-affected zones.

Micro water jet cutting is especially valuable for parts that require precise blanks with high tolerances that must be bent into complex shapes. It’s equally well-suited to rapid prototyping and production applications.

Micro Water Jet Cutting Specifications

Micro water jet recision cutting provides higher accuracies and tighter tolerances than standard cutting processes:

- Position accuracy 0.0001 in. (0.003mm)

- Feature and contour accuracy +/- 0.0004 in (0.01mm)

- Kerf width 0.009 in (0.2 mm) min.

- Kerf width 0.0118 in. (0.3 mm) min. with abrasive

- Maximum workpiece size 24 x 39 inches (600 x 1000 mm)

Download a Data Sheet for the Finecut™ WMC500II Micro Waterjet System

Review the precision capabilities, tolerances, and application strengths of the Finecut™ WMC500II.

Water Jet Cutting – Additional Resources

Why Choose Fathom for Water Jet Cutting?

-

We have decades of experience doing water jet and micro water jet cutting for high-precision parts.

-

We specialize in quick turnaround of prototype sheet metal parts.

-

We can handle your metal forming projects from concept and prototyping to production – one point of accountability.