PolyJet Project / / 3D Printed Models for Oakland’s Mayor

3D Printed Models For Oakland’s Mayor

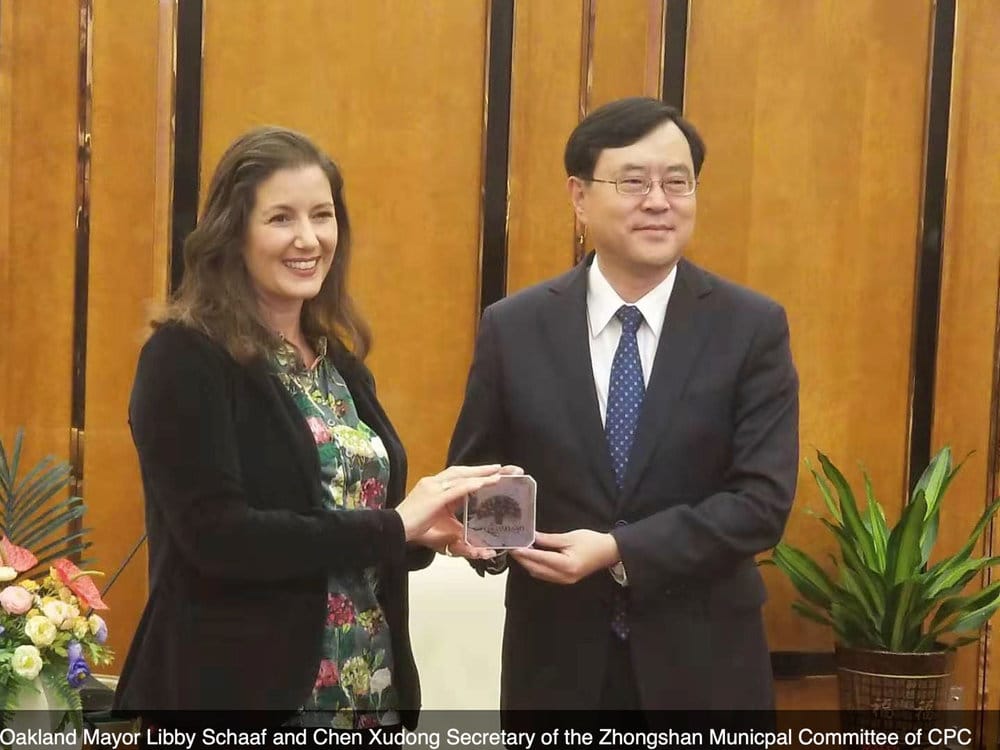

Symbol of Oakland’s Innovative Spirit, Mayor Libby Schaaf Presented PolyJet Models To Oakland’s Sister Cities In China During A Trip To Promote Exchanges In Education, Technology & Culture

Industrial Designer Ava DeCapri on Fathom’s Engineering & Design Team brought these models to life for Oakland’s Mayor by utilizing a PolyJet-based 3D printer (Stratasys J750) at its production center located in the Jack London Neighborhood. Designed in the spirit of Oakland’s rapid growth in technology and its history as a progressive city, DeCapri also chose to highlight its iconic Oak tree logo. These gifts represent the creativity and diversity that the Oakland community cherishes.

The Project // 10 Custom, 3D Printed Gifts

Featured Method Used // Advanced Slicer

Featured Software Used // Autodesk Fusion 360

Additive Technology Used // PolyJet (Multi-Material & Full-Color)

Fathom Teams // Engineering/Design + Production

Fathom Designer // Ava DeCapri, Industrial Designer

The Part // Fathom’s Engineering & Design Team created custom gifts for the Oakland Mayor’s visit to its ten sister cities in China. The gifts featured the City of Oakland tree logo and the artwork is overlaid on a map of the city. PolyJet was used for this project because of the technology’s speed, multi-material capabilities and accuracy.

The Process / / Fathom experts worked with the mayor’s team to come up with a theme that best suited the engagement. Once the concept was selected, a simplified vector version of the Oakland map and logo was created which could be extruded in 2.5D CAD. The map had to be scaled to size to maintain detail quality for the 3D printing process (the final design was 3D printed in a UV-cured resin with a resolution of .25mm). Once vector files were appropriately sized, CAD files were created quickly using Autodesk Fusion 360. One thing to be mindful of while creating this part was to keep the thickness of the model under 1.5in because the clear PolyJet material can appear hazy with greater thicknesses. Files were processed using GrabCAD Print and 3D printed on one build tray. Once the 3D printing was complete, light sanding was required, followed by a clear coat of gloss paint to give the gift a truly high-quality finish.

Design Guidelines // Fathom’s application and engineering team created this easy-to-use guideline for 3D printing and additive manufacturing technologies—get answers for commonly asked questions specific to designing for PolyJet, SLA, FDM, MJF and SLS. Information includes wall thickness, hole diameter, clearance for assemblies, escape holes, minimum detail, pin diameter, accuracy and standard layer thickness.

Did you know Fathom’s application engineering team offers a course on how to design for additive manufacturing? Check out the Fathom calendar of events for upcoming sessions.

For more information about Fathom’s engineers and designers who can be contracted to support your in-house design teams product development, click thru to read about their expertise and view available services.

Learn more about Fathom’s engineering & design help—start a conversation today!