Fathom’s white-glove service means unwavering attention to quality, speed, and detail at every step of the process. We go beyond what other contract manufacturers offer by taking a customer-centric approach that ensures every project receives the technical guidance and care it deserves.

Most importantly, we make sure every component meets the highest standards of precision and performance, so our customers can count on every part we deliver.

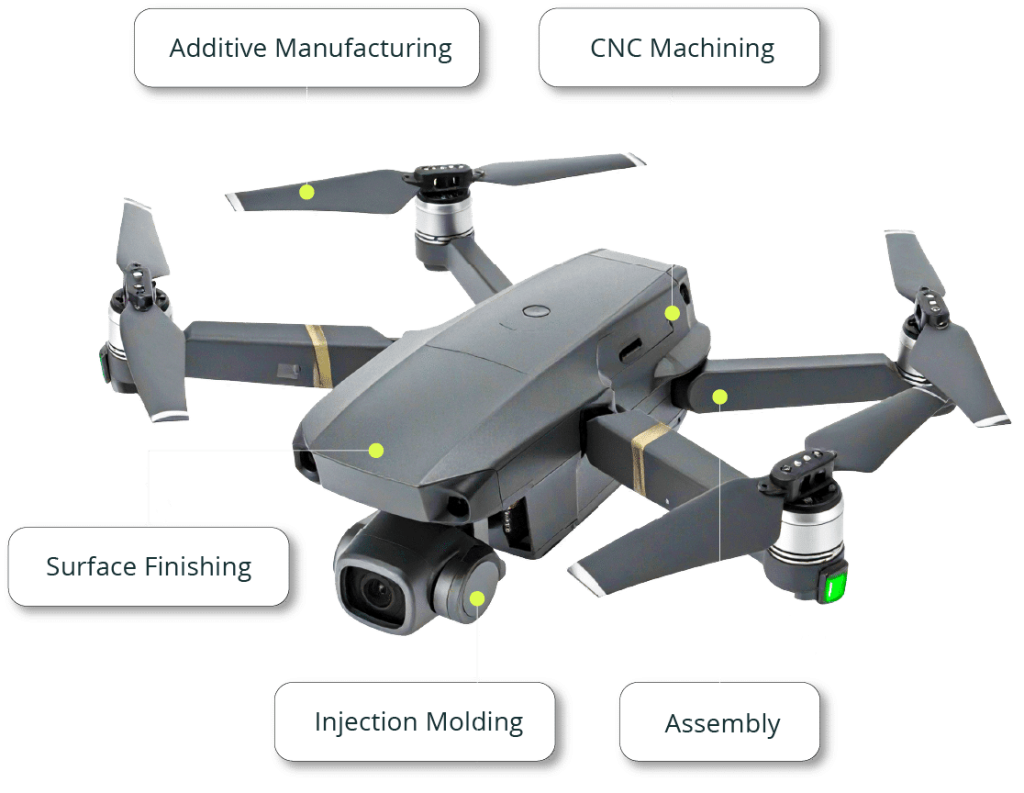

Our engineering and design team works closely with customers from concept through production, helping to refine designs, select the right materials, and identify the most efficient manufacturing methods. With decades of hands-on experience across additive manufacturing, injection molding, CNC machining, and sheet metal fabrication, we anticipate challenges early and provide practical solutions that keep projects on track.

The result is a more collaborative, transparent process that leads to better products and faster launches.